Author Archives: David V. Williamson

- Home

- Author's Archive:

Under Ideal Conditions With Properly Inflated Tires Your Tires Provide

The best way to ensure your tires provide ideal conditions is to properly inflate them. This can be done by using a tire pressure gauge to check the air pressure in each tire and adding or releasing air as needed. You should also check the condition of your tires regularly, looking for any cracks, bulges, or bald spots.

If you notice any damage, it’s important to have your tires repaired or replaced as soon as possible.

Under ideal conditions, with properly inflated tires, your tires provide the following benefits:1. They help keep you safe on the road.

2. They improve your gas mileage.

3. They last longer.

4. They make your ride more comfortable.

Here's why tire inflation matters | Driving ca

A Tilting Motion from Front to Back is Called

A tilting motion from front to back is called a “pitch.” This type of movement is often used to describe the up-and-down movements of an aircraft or boat. When an object pitches, its nose moves up or down in relation to its tail.

When Driving at Night It is Most Important for You to

. .When driving at night, it is most important for you to be aware of your surroundings and use your headlights. Headlights help you see the road in front of you and also help other drivers see your car.

It is also important to drive slower at night so that you have time to react to any potential hazards.

If Your Tire Blows Out the Proper Thing to Do is

. .If your tire blows out, the proper thing to do is pull over to the side of the road and stop. Do not try to continue driving on a flat tire as this can damage your wheel and make it difficult to control your car.

Once you are safely off to the side, you can change your tire or call for help. If you have a spare tire, changing it is relatively simple. First, loosen the lug nuts with a wrench and then jack up your car so that the flat tire is off the ground.

Put the spare tire on in its place and tighten the lug nuts. Lower your car back down and you’re ready to go! If you don’t have a spare, you’ll need to call for roadside assistance or a tow truck to take your car to a service station.

Credit: www.bridgestonetire.com

What Safety Feature Automatically Inflates to Protect an Occupant?

In a frontal collision, your vehicle’s airbag is designed to protect you. The National Highway Traffic Safety Administration (NHTSA) estimates that frontal airbags have saved more than 50,000 lives since they were first introduced in the 1970sHow Airbags Work

Airbags are made of nylon fabric and filled with either nitrogen gas or a chemical propellant. When the airbag sensor detects a certain amount of force—usually from the weight of the driver hitting the steering wheel—it sets off a small explosion that ignites the chemical propellant. This creates a rapid reaction that fills the bag with nitrogen gas in about one-twentieth of a second

The inflation process is extremely fast—faster than you can blink your eye. Once it’s full, the bag quickly deflates so it doesn’t obstruct your view as you continue to drive.Types of Airbags

There are two main types of airbags: driver airbags and passenger airbags. Driver airbags are located in the center of the steering wheel, while passenger airbags are located in the dashboard on the passenger side. In some vehicles, there may also be side-impact or curtain airbags on both sides of the vehicle

Why Airbags Are ImportantAirbags provide invaluable protection in frontal collisions, which account for nearly half of all traffic fatalities each year. According to NHTSA data, frontal air bags saved 2,788 lives in 2017 alone.

Wearing a seatbelt is still your best defense against being ejected from your vehicle or sustaining serious injuries in a crash, but an properly deployedairbag can make all the difference

What is Estimated Total Stopping Distance under Ideal Conditions?

When you are driving, it is important to be aware of your estimated total stopping distance under ideal conditions. This is the distance it would take for your vehicle to stop if you were traveling at a constant speed and had no other vehicles or obstacles in front of you. If you need to stop suddenly, it is important to know how much space you will need in order to come to a complete stop.

The estimated total stopping distance under ideal conditions is based on the speed that you are traveling at when you begin to brake. The faster you are going, the longer it will take for your vehicle to come to a complete stop. For example, if you are driving 30 miles per hour and begin braking, it will take approximately 96 feet for your vehicle to come to a complete stop.

However, if you double your speed to 60 miles per hour, it will now take approximately 384 feet for your vehicle to come to a complete stop.It is important to keep in mind that these estimates are based on ideal conditions and do not account for any real-world factors that could impact your ability to stop. For example, road conditions, weather conditions, and the weight of your vehicle can all affect how quickly your vehicle comes to a stop.

Additionally, if there is traffic or other obstacles in front of you when you attempt to brake, it may take even longer for your vehicleto come completely stopped.In conclusion, knowing your estimated total stopping distance under ideal conditions can help you be better prepared in case of an emergency situation where sudden braking is necessary. Remember that this estimate does not account for any real-world factors that could impact your abilitytoStop so always use caution when driving and give yourself plenty of space between yourself and the car ahead ofyou just in case!

When Tires are Underinflated It Leads to Quizlet?

Underinflated tires can lead to a number of problems, including decreased fuel economy, increased wear and tear on the tires, and reduced handling. Tires that are underinflated by just 10% can decrease fuel economy by up to 2%, so it’s important to keep your tires properly inflated. You should check your tire pressure at least once a month, and more often if you’re frequently driving on rough roads or in extreme weather conditions.

If you notice that your tires are consistently underinflated, there may be a problem with your tire pressure sensor or valve stem.

What Indicates the Expected Life of a Tire?

What indicates the expected life of a tire?Tires are designed to last for a certain number of miles. The number varies depending on the type of tire, but most passenger tires have a lifespan of around 40,000 to 50,000 miles.

If you regularly rotate your tires and take care of them, they should last closer to the higher end of that range. However, if you don’t maintain your tires properly, they could start showing signs of wear at much lower mileages. There are a few different indicators that can help you tell when it’s time to replace your tires.

One is simply the age of the tire. Even if a tire hasn’t been used very much, it will still degrade over time due to exposure to sunlight and other environmental factors. So if you have an old Tire that you’re not sure about, it’s best to err on the side of caution and get it replaced.

Another indicator is tread depth. Most tires have treadwear indicators molded into them in several places around the circumference of the tire. Once the tread gets down to those indicators, it means that the tire only has 1/16th inch (1.6 mm)of tread remaining all around its surface.

At that point, it’s time to replace the tire since it won’t be able to grip the road as well anymore and could be more susceptible to punctures or blowouts. You can measure tread depth with a simple gauge or by using a penny – just insert it into the tread head-first and if Lincoln’s head is visible at any point then you know you’re at or below 1/16″.

Finally, another way to tell that your tire needs replacing is by looking for cracks or splits in the sidewall .

These can happen from impacts (like hitting a pothole) or from prolonged exposure to UV rays from sunlight . If you see any cracks , no matter how small , it’s time for a new tire since those cracks can leadto bigger problems down the line .

Conclusion

Your tires are one of the most important parts of your car, and it is important to make sure they are properly inflated. Under ideal conditions, with properly inflated tires, your tires provide a comfortable ride, good traction, and long life. However, if your tires are not properly inflated, you may experience a number of problems, including a bumpy ride, poor traction, and shortened tire life.

Wheelbarrow Tire Valve Stem Replacement

replacing a wheelbarrow tire valve stem is a simple process that anyone can do with the right tools and a little bit of know-how. the first step is to deflate the tire completely using a tire inflator or by letting all the air out manually. next, remove the old valve stem from the rim of the wheelbarrow by unscrewing it with a wrench.

once the old valve stem is removed, screw in the new one until it’s snug. then, re-inflate the tire to its proper pressure using an air compressor or pump. finally, check that the new valve stem is secure by giving it a few good pumps.

If you have a flat tire on your wheelbarrow, the first thing you’ll need to do is remove the tire. Once the tire is off, locate the valve stem and unscrew it from the wheel. To replace the valve stem, simply screw on a new one in its place.

How To: Replace Tire Valve Stem & Break Bead On Wheelbarrow YOURSELF!

Lawn Mower Tire Valve Stem Size

If you’re a lawn care enthusiast, then you know that having the right tires on your mower is important. Not only do they help with traction and stability, but they can also affect the level of comfort you feel while mowing. One thing you might not have considered, however, is the valve stem size on your lawn mower tires.

Most people don’t think about the valve stem size when it comes to their tires, but it’s actually an important factor to consider. The valve stem size will determine how much air you can put in your tires and how easily you can check the pressure.There are two main types of valve stems: Schrader valves and Presta valves.

Schrader valves are the most common type of valve stem and are typically found on car tires. They’re easy to use and allow for a lot of air to be put into the tire. Presta valves are often found on bicycle tires and are less common on lawn mower tires.

They require a special adapter to be used with a standard air pump and don’t allow for as much air to be put into the tire.When choosing a valve stem for your lawn mower tire, it’s important to consider what type of pump you’ll be using and how much air you need to put into the tire. If you plan on using a standard air pump, then a Schrader valve would be your best bet.

However, if you want to save some money or if you only need to add a small amount of air to your tire, then a Presta valve would suffice.

Valve Stem for Lawn Mower Tire

If you have a lawn mower, chances are you will eventually need to replace the valve stem. The valve stem is the part of the tire that allows air to enter and exit. Over time, it can become worn or damaged, which can lead to leaks.

Replacing the valve stem is a relatively simple process, and doing so can help extend the life of your tires.When shopping for a new valve stem, be sure to get one that is compatible with your lawn mower’s tires. You’ll also want to make sure it is the right size – too small and it won’t fit properly; too large and it could cause problems with the tire.

Once you have the correct valve stem, simply remove the old one and screw in the new one. Be sure not to over-tighten, as this could damage the threads on the tire itself.With a new valve stem in place, your lawn mower’s tires should be good as new!

Tubeless Tire Valve Stem Sizes

Valve stems come in different sizes and depending on the size of your tire, you will need a specific sized valve stem. A tubeless tire valve stem is slightly larger in diameter than a regular valve stem and has a removable core.The most common tubeless tire valve stem sizes are 40mm and 60mm.

The 40mm size is typically used for road bikes while the 60mm size is used for mountain bikes. There are also other less common sizes such as 48mm and 80mm but these are not as widely available.To determine what size valve stem you need, simply measure the width of your tire from one side to the other.

If it is between 20 and 30 millimeters wide, then you will need a 40mm valve stem. If it is between 30 and 45 millimeters wide, then you will need a 60mm valve stem. And if it is over 45 millimeters wide, then you will need an 80mm valve stem.

Installing a tubeless tire can be tricky so if you are not confident in doing it yourself, take it to your local bike shop and they can help get you set up with the right sized valve stem for your tires.

Small Tire Valve Stem

Small Tire Valve StemMost tires have a small valve stem that sticks out from the wheel. The valve stem is used to let air in and out of the tire.

If you have ever had a flat tire, you know that you need to use a pump or compressor to add air to the tire. The valve stem makes this possible.The valve stem on a tire is usually made of metal and has a small cap that screws on and off.

You will need a special tool, called a valve stem wrench, to remove the cap. Once the cap is off, you can use a pump or compressor to add air to the tire. To let air out of the tire, simply press down on the center of the valve stem with your thumb.

You should check your tires regularly to make sure that the valve stems are tight and not leaking air. If you notice that your tires are losing pressure, it could be due to a leaky valve stem. Take your car to a mechanic or Tire Center so they can fix it for you.

Credit: www.amazon.com

How Do You Change a Valve Stem on a Wheelbarrow?

Assuming you have a standard wheelbarrow with a pneumatic (air-filled) tire, here are instructions for changing the valve stem:1. Prepare your tools. You will need a wrench to remove the old valve stem and another tool, like a screwdriver or pliers, to help pry out the old rubber grommet that seals the hole around the valve stem.

You will also need a new valve stem and rubber grommet.

2. Remove the old valve stem by unscrewing it from the wheel rim with your wrench. Some valve stems have a cap that needs to be unscrewed first before you can access the threads; others may be recessed into the rim so you’ll need to use a pair of needle nose pliers to grab onto it and pull it out far enough to get a grip with your wrench.

3. Once the old valve stem is removed, use your other tool to pry out the old rubber grommet that seals around the hole in the wheel rim. Be careful not to damage the aluminum or steel surface around the hole as you do this.

4. Take your new rubber grommet and place it in position in the hole in the wheel rim.

Make sure it’s seated all way around evenly so there’s an airtight seal when you screw in the new valve stem later on.

5x Place your new valve stem throught he hole in teh wheel rim and screw it on tightly by hand until finger-tight..

Then finish tightening it with your wrench until snug – don’t overdo it or strip out/damage any threads!

Are Tire Valve Stems Universal?

Most people believe that tire valve stems are universal, but this is not the case. There are four different types of valve stems, each with its own unique purpose. The four types of valve stems are: Schrader valves, Presta valves, Dunlop valves, and Woods valves.

Each type of valve stem has a different diameter and thread pitch, so they are not interchangeable.The Schrader valve is the most common type of valve stem found on cars and trucks. It has a diameter of 8mm and a thread pitch of 14mm x 1.5mm.

The Presta valve is smaller in diameter than the Schrader valve (6mm), but has a larger thread pitch (24mm x 1). The Dunlop valve is even smaller in diameter (4mm) and has an extremely fine thread pitch (40mm x 0.6). The Woods Valve is the largest of all four types, with a diameter of 10mm and a thread pitch of 20mm x 1.25″.

So, to answer the question, no—tire valve stems are not universal. Each type serves a specific purpose and must be used accordingly. Be sure to check your vehicle’s owner manual or tire pressure placard to determine which type of valve stem it uses before attempting to add air to your tires!

Can I Replace a Valve Stem Without Removing the Tire?

If you have a leaking valve stem, you may be able to replace it without removing the tire. However, it is always best to remove the tire first to ensure that you can properly inspect and clean the area around the valve stem before installing a new one. If you do not remove the tire, there is a risk that dirt or debris could get into the valve stem hole and cause further damage or leaks.

What Valve Stem Do I Need?

If you’re asking yourself, “What valve stem do I need?” the answer may depend on the type of tire you have. In general, there are four types of valve stems: rubber snap-in, metal snap-in, high pressure (metal), and Presta.Rubber snap-in valve stems are the most common and can be used with all tires.

They’re easy to install and remove, making them a good choice for people who don’t want to deal with the hassle of screwing in a metal valve stem.Metal snap-in valve stems are also common and can be used with all tires. They offer a more secure fit than rubber snap-in valves and are less likely to leak air.

Metal snap-in valves are also more durable than rubber ones and can withstand higher temperatures and pressures.High pressure (metal) valve stems are designed for use with high pressure tires, such as those on cars and trucks. They can safely hold up to 60 psi of air pressure.

High pressure valves are made from brass or steel and have a thicker wall than other types of valves.Presta valves are narrow tubes that screw into the wheel rim. They’re mostly used on road bikes because they allow for fine tuning of tire pressure.

Presta valves must be tightened before use – if they’re not, they will leak air constantly.

Conclusion

If you have a flat tire on your wheelbarrow, you’ll need to replace the valve stem. This is a relatively easy process that anyone can do with a few simple tools.First, you’ll need to remove the old valve stem from the wheelbarrow tire.

You can do this by using a screwdriver or other tool to pry it out of the hole in the tire. Once the old valve stem is removed, simply insert the new one into the hole and screw it in place tightly.Now that the new valve stem is in place, all you need to do is inflate the tire back up to its proper pressure and you’re ready to go!

Tractor Tire Leaking around Valve Stem

If you have a tractor tire that is leaking around the valve stem, there are a few things that you can do to try and fix the problem. First, check the tire to see if the leak is coming from the valve stem itself or from somewhere else on the tire. If it is coming from the valve stem, then you will need to replace the valve stem.

If it is coming from somewhere else on the tire, then you may be able to patch the hole in the tire.

If you have a tractor tire that’s leaking around the valve stem, there are a few things you can do to try and fix the problem. First, check to see if the valve stem itself is damaged or corroded. If it is, you’ll need to replace it.

Next, check the tire pressure. If the pressure is low, inflate the tire to the proper level. Finally, check the wheel for any damage that could be causing the leak.

If you find any cracks or damage, you’ll need to get the wheel repaired or replaced.

Repairing Leaking Valve on Liquid Filled Rear Tractor Tire

Replace Motorcycle Valve Stem Without Removing Tire

If you’ve ever had a flat tire on your motorcycle, you know how frustrating it can be. Not only do you have to remove the tire, but then you have to locate the puncture and patch or replace the inner tube. And if the valve stem is damaged, that’s another repair that needs to be made.

But what if there was a way to replace the valve stem without removing the tire?It turns out there is! With a little bit of know-how, you can replace a motorcycle valve stem without taking off the tire.

Here’s what you need to do:1. Start by deflating the tire completely. You can do this with a hand pump or by using a compressor.

Just make sure all of the air is out of the tire before moving on.2. Next, use a valve stem removal tool to unscrew the old valve stem from the rim. If your old valve stem is damaged beyond repair, simply twist it off with a pair of pliers.

3. Once the old valve stem has been removed, take your new one and screw it into place hand-tight. Be careful not to overtighten as this could damage the new valve stem or cause it to leak air.4. Finally, inflate your tire back up to its recommended pressure and you’re good to go!

Now you can hit the road again without having to worry about a flat tire or damaged valve stem holding you back.

Push in Tractor Valve Stem

If you’re a farmer or rancher, chances are you’ve had to deal with a flat tire on your tractor at some point. And if you have, then you know that changing a tire can be a real pain. But there’s an easy way to make sure that you never have to deal with a flat tire again – simply install a push in valve stem on your tractor!

A push in valve stem is just what it sounds like – a valve stem that pushes into the rim of your tractor’s tire. This type of valve stem is incredibly easy to install, and it’s also much more durable than the standard rubber valves that come installed on most tires. That means that once you’ve got a push in valve stem installed, you can rest assured knowing that your tires will always be properly inflated.

So if you’re tired of dealing with flat tires, make the switch to push in valve stems today! Your tractor will thank you for it.

Valve Stem Hole Repair

If you have a car, you know that there are valves that help to control the air pressure in the tires. Over time, these valves can become damaged, which can lead to problems with maintaining proper tire pressure. If you find yourself in this situation, don’t worry – it is possible to repair a valve stem hole and get your car back on the road.

The first thing you need to do is locate the hole in the valve stem. If it is large enough, you should be able to see it with the naked eye. Once you have found the hole, clean it out so that you have a clear surface to work with.

Next, take a piece of sandpaper and roughen up the area around the hole. This will help the repair material adhere better. Once you have done this, apply a sealant or adhesive designed for use on rubber surfaces.

Be sure to follow the instructions on the package carefully so that you apply an adequate amount.Once the sealant has dried, place a patch over the hole and press it firmly into place. You can find patches made specifically for repairing valve stem holes at most auto parts stores.

Again, be sure to follow any instructions provided by the manufacturer.After allowing ample time for drying (usually 24 hours), check your work by inflating the tire and looking for any leaks around the patched area. If all looks good, put your car back on solid ground and enjoy peace of mind knowing that your valve stem hole has been properly repaired!

Tyre Valve Stem Replacement

If you have a slow leak in your tire, it may be time to replace the valve stem. A new valve stem will ensure that air doesn’t escape from your tire, keeping it properly inflated. Here’s a step-by-step guide to replacing a valve stem on your own:

1. Start by removing the cap from the valve stem. Use a small screwdriver or other tool to pry it off.2. Once the cap is removed, use your fingers to unscrew the core of the valve stem.

Be careful not to lose any parts as you remove it.3. Take the new valve stem and screw on the core tightly by hand. Make sure that there’s no air leakage around the connection.

4. Screw on the cap until it’s snug against the top of the valve stem. You may need to use a small amount of force to get it started, but don’t over-tighten it or you could damage the threads.

Credit: baileylineroad.com

How Do You Fix a Leaking Tractor Tire Valve?

If you have a leaking tractor tire valve, there are a few things you can do to fix it. First, check the valve stem for any damage. If the stem is damaged, it will need to be replaced.

Next, check the O-ring on the valve stem. If it is damaged or missing, it will need to be replaced as well. Finally, check the valve core for any damage.

If the valve core is damaged, it will need to be replaced as well.

How Do You Fix a Leaky Valve Stem on a Tractor?

If your tractor’s valve stem is leaking, there are a few things you can do to fix it. First, try tightening the packing nut. If that doesn’t work, you may need to replace the packing washer.

To do this, remove the packing nut and unscrew the valve stem from the wheel. Pull out the old packing washer and put in a new one. Screw the valve stem back into place and tighten the packing nut.

How Do You Stop a Tire Valve Stem from Leaking?

If you have a tire valve stem that is leaking, there are a few things that you can do to try and stop the leak. First, you will want to make sure that the valve stem itself is not damaged. If it is, then you will need to replace it.

If the valve stem is not damaged, then you can try tightening the nut that holds it in place. This may stop the leak. If this does not work, then you may need to replace the O-ring on the valve stem.

Why is My Tire Leaking around the Valve Stem?

If your tire is leaking around the valve stem, there are a few possible reasons. The first is that the valve stem itself may be defective. If the rubber O-ring or washer that seals the connection between the valve stem and wheel is damaged, leaks can occur.

Another possibility is that the metal core of the valve stem may be corroded, which can also cause leaks.If neither of these is the case, then it’s likely that something is wrong with your tire. A hole in the tread or sidewall can cause air to leak out around the valve stem.

If you have recently hit a curb or pothole hard, this may be the cause. Inspect your tires thoroughly for any signs of damage before taking them to a mechanic or tire shop to have them checked out and repaired if necessary.

Conclusion

If you have a tractor tire that is leaking air around the valve stem, there are a few things that you can do to try and fix the problem. First, make sure that the valve stem is tight and not loose. Next, check to see if there is any debris or dirt around the valve stem that could be causing the leak.

Finally, if all else fails, you may need to replace the valve stem.

How to Remove Tubeless Tire Valve Stem

Removing a tubeless tire valve stem is a simple process that anyone can do with the right tools. The first step is to remove the cap from the valve stem. Then, use a tire lever or another similar tool to pry out the core from the valve stem.

Once the core is removed, you can simply pull out the entire valve stem from the tire. If you are having trouble removing the valve stem, you may need to use a needle nose pliers or other small tool to help grip and pull it out.

- First, you’ll need to remove the wheel from the bike

- To do this, you’ll need to loosen the axle nuts or quick release levers

- Once the wheel is removed, use a tire lever to pry off one side of the tire

- Be careful not to damage the rim

- Once one side of the tire is off, locate the valve stem and deflate the tire completely

- Use a pair of needle-nose pliers to grab onto the base of the valve stem and pull it out of the rim

- If it’s stubborn, you may need to use a small screwdriver or another tool to help pry it out

- Now that the valve stem is removed, you can put on a new one by simply pushing it into place in the rim hole and inflating your tire as usual

How do you install and remove tubeless valve

How to Remove Valve Stem Without Damaging It

Assuming you have a Schrader valve stem (the type with the small pin in the center of the cap), you can use a few different tools to remove it without damaging it.One option is to use a valve core removal tool. This is a small, T-shaped tool that fits over the top of the valve stem.

To use it, simply insert the tool into the valve stem and turn it counterclockwise until the valve core pops out.Another option is to use a pair of needle-nose pliers. Grip the base of the valve stem with the pliers and twist counterclockwise until the valve core comes out.

Be careful not to grip too tightly or you may damage the stem.Once the valve core is removed, you can unscrew and remove the entire valve stem if desired.

Replacing Tubeless Valve Stem Mtb

If you have a tubeless mountain bike tire, then you know that one of the most important parts is the valve stem. Without a properly functioning valve stem, your tire will not hold air and you will not be able to ride. So, if your valve stem is damaged or leaking, it’s important to replace it as soon as possible.

Luckily, replacing a tubeless valve stem is not difficult, and can be done at home with just a few tools. In this blog post, we’ll walk you through the steps of how to replace a tubeless valve stem on your mountain bike.First, start by removing the damaged or leaking valve stem from your tire.

To do this, use a small flathead screwdriver to pry out the retaining nut that holds the valve stem in place. Once the retaining nut is removed, simply pull out the old valve stem.Next, take your new valve stem and insert it into the hole where the old one was located.

Make sure that the new valves taper end is facing downwards so that air can easily enter when you start pumping up your tire.Once the new valve stem is in place, screw on the retaining nut until it’s tight against the rim of your wheel. Then all that’s left to do is inflate your tire using a floor pump or compressor – and you’re ready to ride!

Tubeless Valve O Ring Inside Or Outside

When it comes to tubeless valves, there is some debate about whether the o-ring should be placed on the inside or the outside of the valve stem. There are pros and cons to both sides, so it ultimately comes down to personal preference.If you place the o-ring on the inside of the valve stem, it will create a seal between the rim and the valve stem, which can help to prevent air leaks.

However, it can be difficult to get the o-ring in place if you’re not using a dedicated tool, and it can also be tricky to remove the valve stem without damaging the o-ring.If you place the o-ring on the outside of the valve stem, it’s easier to install and remove, but it’s not as effective at sealing against air leaks. Some people also find that an external o-ring can interfere with tire changes.

So, which is best? Like we said, it’s up to you! Experiment with both methods and see what works best for you.

Best Tubeless Valve Stem Mtb

Mountain biking is a great way to get out and explore the trails. However, before you can hit the trails, you need to have a bike that is ready to go. This means having a good quality mountain bike with all the right gear.

One of the most important pieces of gear for your mountain bike is the tubeless valve stem.A tubeless valve stem allows you to ride without inner tubes. This means that you do not have to worry about punctures or flat tires.

Tubeless valve stems are also much lighter than traditional inner tube setups. This makes them ideal for racing and riding in remote areas where weight is a concern.There are many different brands and types of tubeless valve stems on the market.

So, how do you know which one is right for you? Here are a few things to consider when choosing a tubeless valve stem for your mountain bike:-Compatibility: Make sure that the tubeless valve stem you choose is compatible with your rims and tires.

There are many different standards on the market, so it is important to check compatibility before purchasing.

-Valve Length: Valve length will vary depending on your rim depth. You want to make sure that the valve stem is long enough to reach past the rim bed and extend into the tire cavity.

Otherwise, air may leak out around the edges of the rim and cause problems down the road.

-Construction: Most tubeless valves are made from aluminum or brass. Aluminum valves are typically lighter but more susceptible to damage from rocks or other debris kicked up by your tires.

Credit: www.instructables.com

How Do You Remove the Stem from a Tubeless Tire?

Assuming you want to remove the stem from a tubeless tyre:There are a few reasons you might want to remove the stem from a tubeless tyre. Maybe you’re changing wheels and need to swap tyres, or maybe you have a puncture and need to patch the inner tube.

Whatever the reason, it’s not as difficult as it may seem. Here’s how to do it:1. First, deflate the tyre completely.

This will make it easier to work with and less likely to damage.2. Use a sharp knife or tire lever to pry the bead of the tyre away from the rim. Be careful not to scratch or damage the rim in the process.

3. Once you have one side of the bead pried away, work your way around the circumference of the tyre until both sides are loose. The stem should now be exposed.4. Use pliers or your fingers (if they’re strong enough) to grasp onto the base of the stem and pull it out of the tyre completely.

If there is any resistance, wiggle back and forth until it comes free.

How Do You Remove a Valve Stem from a Tubeless Rim?

Assuming you would like information on how to remove a valve stem from a tubeless rim:There are a few reasons you might need or want to remove the valve stem from your tubeless rim. Maybe you’re changing out your tires and need to get the old ones off, or maybe you’re trying to fix a flat and need to get to the tube.

Whatever the reason, it’s not as difficult of a task as it may seem. Here’s a step-by-step guide on how to remove a valve stem from a tubeless rim:1. To start, deflate your tire completely.

This will make it easier to work with and less likely that you’ll damage anything while trying to remove the valve stem.2. Next, use a tire lever (or something similar) to pry the edge of the tire away from the bead of the wheel. You only need to do this enough so that you can see the valve stem poking through.

3. Once you can see the valve stem, use a pair of pliers (needle nose work best) to grip onto it and unscrew it counterclockwise until it is removed from the wheel entirely. If it’s being stubborn and not coming out easily, try spraying some WD-40 or another lubricant onto the threads before attempting to unscrew again.4. And that’s all there is to it!

Now just reverse these steps when you’re ready to put your new tires on or fix that flat.

How Do You Remove a Tubeless Valve Core Without a Tool?

If you’re like most people, you probably don’t have a tubeless valve core removal tool just lying around the house. But that’s okay! There are a few different ways that you can remove a tubeless valve core without a tool.

One way is to use a pair of needle-nose pliers. Just grab onto the end of the valve core with the pliers and twist it until it pops out.Another way is to use an old spoke (or something similar).

Just insert the spoke into the end of the valve core and twist until it pops out.Once the valve core is removed, you can do whatever you need to do (inflate your tire, add sealant, etc.) and then put the valve core back in when you’re finished. To put the valve core back in, just press it into place with your fingers and then screw it on tightly with your hands.

No need for any tools!

How Do You Remove a Valve Stem from a Tire?

Assuming you would like tips on removing a valve stem from a tire:Tools You Will Need:

-Tire iron

-Valve stem core tool or a small flathead screwdriverInstructions:

1. Loosen the lug nuts on your wheel using the tire iron.

Do not remove them completely.

2. Lift the wheel off of the ground and place it on a jack stand. Again, do not remove the lug nuts completely.

3. Find the valve stem on your tire. It is likely located near the edge of the wheel well on one side of your car. The valve stem will have a small cap covering it.

Use your fingers to unscrew this cap and set it aside.

4a) If you are using a valve stem core tool: Insert the tool into the hole in the center of the valve stem and twist until you feel resistance. Then, continue twisting until you hear air hissing out of the tire – this means that you have successfully removed the valve stem core from its housing in the tire (see image 1 below).

Be careful not to lose this small metal piece – keep it in a safe place until you are ready to reinsert it later on!4b) If you are using a small flathead screwdriver: Gently insert the tip of your screwdriver into hole in center of valve stem (you may need wiggle it around slightly to find just right spot). Once found, apply gentle pressure while twisting counter clockwise until air starts hissing out (see image 2 below).

This means that have successfully removed valve stem core from its housing in tire – be careful not to lose this small metal piece! Keep safe place until ready to reinsert later on5) With either method above, once air starts hissing out, stop removing tool/screwdriver and leave Valve stem core removed for now (leaving hole open). This will allow all remaining air to escape from tire so that we can proceed with next steps without risk overinflating Tire when inserting new Valve Stem later on6) Proceed by loosening lug nuts completely and then removing wheel from car altogether by hand – be careful as wheels can be heavy!

Conclusion

Most tubeless tires come with a valve stem already installed. If you need to remove the valve stem for any reason, follow these steps:1. Use a tire iron or screwdriver to loosen the nut that holds the valve stem in place.

2. Pull the valve stem out of the tire.3. Replace the valve stem if necessary, and then reinstall it by following the above steps in reverse order.

How to Fix a Broken Presta Valve

If you have a broken Presta valve, don’t despair! While it may seem like a daunting task, with a little patience and the right tools, you can easily fix it. Here’s what you’ll need:

-A flat head screwdriver

-A new Presta valve (if the old one is beyond repair)

-Some pliers

-Patience!First, start by unscrewing the cap from the Presta valve. Next, use your flat head screwdriver to loosen the nut that holds the valve in place.

Be careful not to damage the threads. Once the nut is loose, carefully remove the valve from the tire. If there is any debris or dirt on the threads, be sure to clean them off before proceeding.

Now it’s time to replace the old valve with a new one. Start by screwing on the new valve (again, being careful not to damage the threads). Next, use your pliers to tighten down the nut.

Once everything is tight and secure, screw on the cap and give it a good pump! You’re now ready to hit the road again with a fully functioning Presta valve.

- If you have a broken presta valve, there are a few steps you can take to fix it

- Remove the wheel from the bike and remove the tire

- Inspect the valve stem to see if it is bent or damaged in any way

- If the valve stem is bent, you can try to straighten it with a pair of pliers

- If the valve stem is damaged beyond repair, you will need to replace it

- Once you have repaired or replaced the valve stem, re-install the tire and wheel on the bike

How To Fix A Leaky Tire Presta Valve Stem Valve Core Bike Blogger

How to Remove Presta Valve Core Without Tool

Assuming you don’t have a Presta valve core removal tool, there are still a few ways that you can remove the valve core.One way is to use a small flathead screwdriver. Simply unscrew the top of the valve until the core is exposed, and then use the screwdriver to pry out the core.

Another way is to use a nail or another sharp object. Again, unscrew the top of the valve until the core is exposed. Then, insert the nail into the hole in the center of the valve and twist until the core pops out.

If neither of these methods work, you may need to replace your inner tube entirely.

Broken Presta Valve Tubeless

If you have a broken Presta valve on your tubeless tire, don’t worry! With a few simple steps, you can easily fix it.First, remove the wheel from the bike and take off the tire.

Next, use a pair of pliers to remove the broken valve stem from the rim. Once the stem is removed, clean out any debris from the hole in the rim.Now it’s time to install the new valve stem.

Start by screwing on the metal base (or “nut”) onto the threads of the new valve stem. Then insert the stem into the hole in the rim and hand-tighten it until it’s snug against the side of the rim.

Can You Ride With a Broken Presta Valve

If you have a broken Presta valve, you may be wondering if you can still ride your bike. The good news is that you can continue to use your bike even with a broken valve. However, there are some things that you need to keep in mind.

First, it is important to understand how the Presta valve works. The valve is designed to allow air to enter the tube when the pump is attached and then seals the opening when the pump is removed. This prevents air from escaping from the tube while you are riding.

However, if the valve itself is damaged, it may not seal properly and air can escape. This will cause your tire to lose pressure and could lead to a flat tire. As such, it is important to check your tires regularly for any signs of leakage.

If you do find that your Presta valve is leaking, there are a few options for fixing it. One option is to replace the entire valve with a new one. Another option is to try and repair the existing valve with a patch kit or by replacing just the O-ring on the valve stem.

Either way, it is important to make sure that the repair is done properly so that air does not leak out again.In summary, yes you can ride with a broken Presta valve but there are some things that you need to keep in mind in order to avoid flats and other issues.

Replace Presta Valve Core

If you have a Presta valve and need to replace the valve core, here’s how:First, remove the cap from the valve. Next, use a valve core removal tool to unscrew the old valve core.

Once the old valve core is removed, screw in the new one. Make sure it’s tight! Finally, put the cap back on and you’re done!

Credit: denveraddictions.com

Can Presta Valves Be Repaired?

Yes, Presta valves can be repaired. There are a few ways to do this, but the most common is to use a Presta valve stem tool. This tool is inserted into the valve stem and turned clockwise until it pops out.

Once the tool is removed, the old valve stem can be pulled out and a new one can be inserted.

How Do You Change a Presta Valve Stem?

Assuming you’re talking about a bicycle wheel, the first thing you need is a presta valve adapter, which allows you to use a standard pump head to inflate the tire. You’ll also need a new presta valve stem – these are available at most bike shops. To remove the old stem, unscrew the retaining nut and pull out the stem.

To install the new one, simply reverse the process – screw in the new stem and tighten the retaining nut.

How Do You Fix a Broken Bike Valve Stem?

A broken bike valve stem can be a serious problem if you’re trying to inflate your tires. The good news is, it’s an easy fix. All you need is a new valve stem and some patience.

1. Remove the old valve stem from the tire. You’ll need a tire lever or something similar to pry it out. Be careful not to damage the rim of the tire.

2. Install the new valve stem in the same hole as the old one. Again, be careful not to damage the rim of the tire. You may need to use a little force to get it started, but it should go in easily enough.

3. Inflate your tire to the desired pressure using a hand pump or air compressor. Make sure that the new valve stem is holding air before you put your bike back on the road!

How Do You Fix a Leaky Presta Valve?

If you have a leaky presta valve, there are a few things you can do to fix it. First, check to see if the valve core is tight. If it is, then unscrew it and remove the O-ring.

Inspect the O-ring for any damage or debris and clean or replace it as needed. Next, screw the valve core back in and inflate the tire to the recommended pressure. If the tire still leaks, then you may need to replace the entire presta valve.

Conclusion

A broken Presta valve can be a real pain, preventing you from being able to pump up your tires. But don’t worry, it’s not the end of the world. With a few simple tools, you can easily fix a broken Presta valve and get back on the road.

First, start by removing the broken valve core with a pair of needle nose pliers. Next, use a small screwdriver to remove the rubber O-ring from the top of the valve stem. Once that’s done, insert a new valve core and screw it in place.

Finally, put the rubber O-ring back on and screw on the cap. That’s it! Your Presta valve is now fixed.

How to Buy All Season Tires

If you live in an area with cold winters and hot summers, then you know how important it is to have a good set of all season tires. All season tires are designed to perform well in a variety of conditions, making them the perfect choice for year-round driving. But with so many different brands and models on the market, how do you choose the right all season tires for your car?

Here are a few tips to help you make the best decision.

- Look for a tire that has the All Season designation on it

- Find the right size for your vehicle

- Consider your driving needs and choose a tire accordingly

- Compare prices and reviews to find the best deal on all season tires

Tire Buying Guide (Interactive Video) | Consumer Reports

All Season Tires Sale Costco

Looking to buy new all-season tires? You’re in luck! Costco is currently having a sale on all-season tires.

Here are some of the best deals:Michelin Defender LTX – $169.99 per tirePirelli Scorpion Verde All Season Plus – $179.99 per tire

Goodyear Assurance Tripletred All-Season – $184.99 per tireIf you’re looking for a great deal on all-season tires, be sure to check out Costco’s current sale!

Credit: www.motortrend.com

How Do You Get All-Season Tires?

If you’re looking to buy all-season tires, there are a few things you need to keep in mind. First, all-season tires are designed to provide good traction and handling in a variety of conditions, including wet weather and light snow. However, they’re not necessarily the best choice for everyone.

If you live in an area with very cold winters or a lot of snow, you’ll probably be better off with winter tires.That said, if you decide that all-season tires are right for you, there are a few things to keep in mind when shopping. First, make sure you buy tires that are appropriate for your vehicle.

All-season tires come in different sizes and have different load ratings; if you buy too small of a tire, it could impact your gas mileage or cause other problems.Second, pay attention to the tread wear rating when choosing all-season tires. This number indicates how long the tire is expected to last; generally speaking, the higher the number, the longer the tire will last.

Of course, this is just an estimate – how long your tire lasts will also depend on how well you take care of it and how often you drive on rough roads or in adverse conditions.Finally, don’t forget to factor in the cost of all-season tires when making your decision. They tend to be more expensive than summer or winter tires (although prices vary depending on brand and size), so make sure you budget accordingly.

When Should I Buy All-Season Tires?

If you’re wondering when the best time to buy all-season tires is, the answer is typically in the late spring or early summer. This is because all-season tires are designed to perform well in a variety of conditions, including both warm and cold weather. All-season tires also tend to have a longer lifespan than other types of tires, so they can be a good investment if you plan on keeping your car for a while.

How Do I Know If My Tires are All-Season?

If you’re not sure whether or not your tires are all-season, there are a few things you can look for. First, check the sidewall of the tire. All-season tires will typically have a symbol that looks like a snowflake within a mountain.

This indicates that the tire is designed for winter driving conditions.Another way to tell if your tires are all-season is to look at the tread pattern. All-season tires will have wider grooves than summer or winter tires.

These grooves help to channel away water and slush so that you can maintain traction in wet weather conditions.If you’re still unsure, you can always consult your owner’s manual or ask a professional at your local tire shop.

Is There a Difference between All-Weather Tires And All-Season Tires?

There is a difference between all-weather tires and all-season tires. All-weather tires are designed to perform well in all types of weather, while all-season tires are designed to perform well in specific types of weather. All-weather tires are typically more expensive than all-season tires, but they offer better performance and traction in all types of conditions.

Conclusion

It’s finally that time of year again. The weather is starting to get colder and the leaves are falling off the trees. You know what that means?

It’s time to start thinking about getting your all season tires! Here are a few things to keep in mind when you’re shopping for all season tires:1. Make sure you know the size of tire that you need.

You can find this information in your car’s owner’s manual or on the placard located on the doorjamb of the driver’s side door.2. Pay attention to tire tread depth. All season tires typically have a tread depth of at least 10/32″.

3. Consider getting an all-wheel drive (AWD) vehicle if you live in an area with particularly bad winter weather conditions. This will help improve your traction and safety on icy or snowy roads.4. Don’t forget about tire pressure!

How Much Is Air Pressure? You Should Know

The air pressure at sea level is about 1013.25 millibars. This is the atmospheric pressure on Earth that is caused by the weight of air in the atmosphere. The higher the altitude, the less air there is above, so the atmospheric pressure decreases with altitude. At high altitudes, such as those found on mountaintops, the air pressure can be much lower than it is at sea level.

The air pressure is the force per unit area exerted by the weight of air. The SI unit for air pressure is the pascal (Pa), which is equal to one newton per square meter (N/m2). The average atmospheric pressure at sea level is 1013.25 hPa, or 1 atmosphere (atm).

Table of Contents

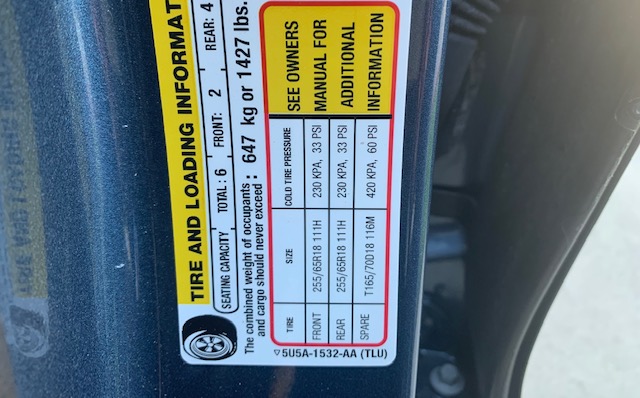

Car Tyre Air Pressure Front And Rear

Most people know that their car has tyres, and that these need to be inflated in order to work properly. However, many don’t realise that there is usually a different air pressure required for the front and rear tyres. The correct tyre pressures for your car can be found in the owner’s manual, or on a sticker inside the driver’s door frame.

It’s important to check and adjust your tyre pressure regularly, as even a small change can impact how your car handles on the road. Under-inflated tyres will result in reduced handling and braking ability, as well as increased fuel consumption due to more rolling resistance. Over-inflated tyres can also cause problems, as they are more likely to suffer from punctures and blowouts.

To check your tyre pressure, you will need a reliable pressure gauge. Once you know the current pressures of each tyre, compare them to the recommended figures and inflate or release air accordingly. Don’t forget to check all four tyres!

What Should My Tire Pressure Be in Summer

It’s no secret that warmer weather can lead to lower tire pressure. The heat causes the air inside your tires to expand, which means you’ll need to add a bit of air to maintain the proper pressure. But how much air should you add?

The answer depends on a few factors, including the type of tire you have and the manufacturer’s recommendations. For most passenger vehicles, the recommended tire pressure for summer is between 32 and 35 PSI (pounds per square inch). However, some tires may require a higher or lower pressure, so it’s always best to check your owner’s manual or the sticker inside your driver’s door before making any adjustments.

If you’re not sure what PSI your tires should be at, start by inflating them to the middle of the range (33-34 PSI). Once you’ve done that, take your vehicle for a short drive and then recheck the pressure. If everything feels good, you’re all set! If not, adjust as needed until you find the perfect balance.

Normal Tire Pressure for SUV

Tires are one of the most important parts of your vehicle, and it’s important to keep them inflated to the proper pressure. Overinflated tires can lead to a bouncy ride, while underinflated tires can cause premature wear and tear. Most SUV’s have a recommended tire pressure of 30 psi, but it’s always best to check your owner’s manual or the placard on your doorjamb for the specific number.

If you don’t have either of those handy, you can usually find the correct tire pressure in the glove box. If you notice that your tires seem low on air, don’t hesitate to add some air. You can find air pumps at most gas stations, and they usually only cost a few quarters. It’s better to be safe than sorry when it comes to your tires!

How to Check Tire Pressure

It’s important to keep your tires inflated to the proper pressure. Not only does it help with gas mileage, but it also helps with tire wear and safety. The proper tire pressure for your vehicle can be found in the owner’s manual or on a sticker inside the driver’s door.

There are a few different ways that you can check your tire pressure. You can either use a digital or analog gauge. If you don’t have a gauge, you can also go to a service station and have them check it for you.

To check your tire pressure with a gauge, start by removing the cap from the valve stem on your tire. Place the gauge on the valve stem and press down firmly to get an accurate reading. If you’re using an analog gauge, read the number that lines up with the pointer.

If you’re using a digital gauge, read the number that is displayed. Once you have your reading, compare it to what is listed in your owner’s manual or on the sticker inside your door (for most vehicles, this will be between 30 and 35 PSI). If your tires are low, use a air compressor or hand pump to add air until they reach the proper pressure. Once they are inflated properly, replace the valve stem caps.

Tire Pressure Calculator

If you’re like most people, you probably don’t think much about your car’s tires until there’s a problem. But keeping your tires properly inflated is actually very important for a number of reasons. For one thing, it can improve your gas mileage by up to 3%.

It can also extend the life of your tires and make them safer to drive on. But how do you know what the right tire pressure is? That’s where a tire pressure calculator comes in handy.

Just enter in some basic information about your vehicle and its tires, and the calculator will do the rest. In general, you’ll want to keep your tires inflated to the manufacturer’s recommended level. But if you’re going to be carrying extra weight (like passengers or cargo), you may need to adjust your tire pressure accordingly.

Once you know what the right pressure is, check your tires at least once a month using a tire gauge. If they’re low, add air until they reach the proper level. And that’s all there is to it! By taking just a few minutes to check and inflate your tires regularly, you can save yourself time and money down the road.

Credit: evanstire.com

Is 40 Psi a Lot of Pressure?

No, 40 psi is not a lot of pressure. In fact, it’s pretty standard for many applications. For example, car tires are typically inflated to between 30 and 35 psi.

What is the Pressure of a Car Tire?

The pressure of a car tire is the amount of air that is inside the tire. This is measured in pounds per square inch (PSI). The recommended PSI for most cars is between 30 and 35.

How Much Air Pressure is Too High?

You know how sometimes you can just tell that a storm is brewing? The air pressure changes and everything feels a little off. That’s because air pressure is dropping, which means low pressure systems are on the way.

But what happens when the opposite occurs and air pressure starts to rise? Well, that’s when things can get a bit uncomfortable. Rising air pressure indicates high pressure systems, which usually means clear skies and good weather but it can also mean some not-so-fun side effects.

For some people, an increase in air pressure can lead to headaches or migraines. It can also cause fatigue, dizziness, and even nausea. And in extreme cases, it can trigger anxiety attacks or panic disorders.

So how much air pressure is too high? Unfortunately, there’s no easy answer to that question as everyone reacts differently to changes in barometric pressure. However, most experts agree that anything above 30 inches of mercury (or 1013 millibars) is considered dangerously high.

At this level, the body struggles to compensate for the sudden change and symptoms like those mentioned above become more likely. Of course, it’s important to keep in mind that atmospheric conditions are constantly changing so what may be considered “high” today may not be tomorrow. That’s why it’s always best to pay attention to your own body and how it responds to different levels of air pressure.

If you start feeling any strange symptoms, make sure to take a break from whatever you’re doing and rest until they subside.

Bike Tire PSI: How Much Air Should You Put in Your Bike Tire? || REI

How Much is the Air Pressure at Sea Level?

The air pressure at sea level is about 1013.25 millibars. This is the atmospheric pressure on Earth at an altitude of 0 meters (0 feet). The average person experiences this pressure every day. It’s the pressure that pushes against your skin and keeps your lungs from collapsing. At higher altitudes, the air pressure is less than it is at sea level.

Frequently Asked Questions (FAQs)

1. What Is Air Pressure?

Air pressure is the force exerted by the weight of air on a given area. It is measured in units called millibars or atmospheres, and it is crucial in forecasting weather and understanding the earth’s climate.

2. How Is Air Pressure Measured?

Air pressure is typically measured with a barometer. The standard atmospheric pressure at sea level is about 1,013 millibars or 1 atmosphere.

3. Why Does Air Pressure Change With Altitude?

Air pressure changes with altitude because the higher you go, the less air there is above you to exert pressure. This is why it’s harder to breathe at high altitudes – there’s less pressure to push oxygen into your lungs.

4. How Does Air Pressure Affect The Weather?

Air pressure affects the weather by influencing wind patterns and precipitation. Low-pressure areas are often associated with cloudy, rainy, or snowy weather, while high-pressure areas usually bring clear skies.

5. What Is The Difference Between High Pressure And Low Pressure?

High pressure refers to areas where the air pressure is higher than the surrounding areas, usually characterized by clear, calm weather. Low pressure refers to areas where the air pressure is lower, often resulting in clouds, wind, and precipitation.

Conclusion

The blog post discusses how air pressure affects different objects. It explains that the air pressure is greater at lower altitudes because there is less air above the object to push down on it. The article also states that air pressure decreases as altitude increases. This decrease in pressure is why airplanes fly; the wings create lift by deflecting some of the downward-moving air, which causes the airplane to rise.

How Do You Know When Your Tires Need Air

You may not think about your tires much until you have a flat, but they are an important part of your car. Your tires need air to be able to grip the road and provide a comfortable ride. You should check your tire pressure at least once a month.

If you notice that your tires are low on air, add air until they are at the recommended level. You can usually find this information on the inside of your driver’s door or in your car manual.

If your vehicle is like most, you have a tire pressure monitoring system (TPMS) that alerts you when your tires are low on air. But what if your TPMS is broken or malfunctioning? How can you tell when it’s time to add air to your tires?

Here are a few signs that indicate your tires may be low on air:1. Your car is handling differently. If you feel like your car is pulling to one side or the other, or if the ride feels rougher than usual, it could be a sign that one or more of your tires are low on air.

2. You see cracks or bulges in the sidewalls of your tires. These are signs of weakened structure and could lead to a blowout if not addressed. Check your tire’s PSI rating and inflate accordingly.

3. Your mileage suffers. Believe it or not, underinflated tires can negatively impact fuel efficiency by as much as 3%. Keep an eye on your gas gauge and top off those tires when needed!

How to check Tyre and Wheel Air Pressures Visually daily in Car or Truck

How to Check Tire Pressure

Most people know that it’s important to check their tire pressure regularly. But many don’t know how to do it properly. Here are some tips on how to check your tire pressure:

1. Get a tire pressure gauge. You can find one at most auto parts stores or online.2. Remove the cap from the valve stem on your tire (the part that sticks out).

3. Press the gauge onto the valve stem and hold for a few seconds until you hear a hissing sound. This means that the gauge is getting a reading from your tire.4. Look at the number on the gauge and compare it to the recommended pressure for your tires (this information is usually listed on the side of your tires).

If your tire pressure is low, add air until it reaches the proper level; if it’s high, let some air out until it reaches the proper level.

How to Know Which Tire Needs Air Without Gauge

If you have a tire that needs air, but you don’t have a gauge to check the pressure, there are still ways to tell. First, try pressing on the tire with your hand. If it feels soft and squishy, then it definitely needs more air.

Another way to tell is by looking at the tread. If the tread looks flat or worn down, that’s another sign that it’s time to add some air.If you’re not sure whether or not your tire needs air, err on the side of caution and add some anyway.

It’s better to have slightly too much air in your tires than not enough. Underinflated tires can lead to all sorts of problems, including decreased fuel efficiency and increased wear and tear. So if you’re unsure, just add a little bit of air and check back later to see if it needs more.

How to Check Air Pressure in Tires at Gas Station

If you’re like most people, you probably don’t think much about your car’s tires. But they play a vital role in keeping you safe on the road. That’s why it’s important to check their air pressure regularly.

Here’s how to do it:1. Find the right tire gauge. There are two types of tire gauges: analogue and digital.

Analogue gauges are the cheaper option, but they can be less accurate than digital ones. If you can, get a digital gauge.2. Locate the valve stem on your tire.

This is the small metal cap on the side of the tire that allows air to enter or escape.3. Remove the valve cap and press the tip of the gauge onto the valve stem until you hear a hissing sound. This means that air is coming out of your tire and into the gauge.

Keep hold of the gauge until it registers a reading on its display screen or dial (this will take a few seconds). Alternatively, if you’re using an analogue gauge, wait for the needle to settle on a reading before removing it from the valve stem.4 .

Compare your reading to what’s printed on the side of your tire . Most tires have their recommended pressure levels printed on them (usually in PSI – pounds per square inch). If your reading is lower than this, then you need to add more air to your tires; if it’s higher, then let some air out until it reaches the correct level .

You can usually do this at any gas station by using an air compressor . Just insert coins or tokens into machine , attach its hose to your tire ‘s valve stem , and turn it on . It’ll automatically stop when it reaches t he desired pressure level .

Do You Have to Turn Car off When Putting Air in Tires

When it comes to adding air to your tires, there is some debate over whether or not you should turn your car off. Some people say that it’s necessary in order to get an accurate reading, while others claim that it doesn’t make a difference. So, what’s the verdict?

Turning your car off when adding air to your tires is not required, but it can help you get a more accurate reading. If you don’t turn your car off, the gauge may be affected by the engine’s vibration and give you a false reading. However, as long as you’re careful and keep an eye on the gauge, adding air with the engine running shouldn’t be a problem.

In short, there is no harm in turning your car off when adding air to your tires. If you’re worried about getting an accurate reading, it’s best to err on the side of caution and turn off your engine.

Credit: www.wikihow.life

How Do I Tell If My Tire Needs Air?

It’s important to check your tires regularly to make sure they are properly inflated. Under-inflated tires can lead to decreased fuel efficiency, increased tire wear, and a potentially dangerous blowout. Here are a few ways to tell if your tire needs air:

1. Check the tire pressure with a gauge. The ideal pressure for most passenger vehicles is between 32 and 35 psi (pounds per square inch). If the pressure is below this range, add air until it reaches the proper level.

2. Take a look at the treads. If they appear low or flat, it’s time to add air. Air helps maintain the proper shape of the tread, which is essential for gripping the road and providing traction.

3. Pay attention to how the vehicle feels when you’re driving. If it seems like the ride is rougher than usual or that the car is pulling to one side, low tire pressure may be to blame.If you’re not sure how much air to add, consult your owner’s manual or ask a professional at a service station.

How Do You Know If Your Tire Pressure is Low?

It’s important to check your tire pressure regularly to ensure safe driving conditions and prolong the life of your tires. Here are a few ways to tell if your tire pressure is low:1. Check the PSI rating on the side of your tires.

The recommended PSI will vary depending on the type of vehicle you’re driving.2. Use a tire pressure gauge to measure the air pressure in each tire. You can find a gauge at most auto parts stores.

3. Compare your readings to the PSI rating on the side of your tires. If they’re significantly different, then your tire pressure is likely low and needs to be adjusted accordingly.4. Look for visual clues that may indicate low tire pressure, such as cracks or bulges in the sidewalls of your tires.

How Often Should You Put Air in Your Tires?

It is important to keep your tires properly inflated for several reasons. First, underinflated tires can lead to decreased fuel efficiency. Second, they can cause premature tire wear.

Third, they can make your car handle poorly and decrease its stability, making it more difficult to control on the road.So how often should you put air in your tires? It depends on a few factors.

If you drive mostly on highways, you can typically get away with inflating your tires once a month or so. But if you do a lot of stop-and-go driving or live in an area with lots of potholes, you may need to inflate them more often. The best way to know for sure is to check your tire pressure regularly (at least once a week) using a reliable tire gauge.

You can find one at most auto parts stores.When checking your tire pressure, be sure to do it when the tires are cold (meaning they haven’t been driven for at least three hours). This will give you the most accurate reading.

If you find that your tires are low on air, add enough air until they reach the recommended PSI level (you’ll find this information either in your car’s owner’s manual or on a sticker inside the driver’s door).

Can I Drive If My Tire Needs Air?

If your tire needs air, you can drive to a nearby gas station or service center to fill it up. However, if the tire is completely flat, you’ll need to replace it with a new one. Driving on a flat tire is dangerous and can damage your wheel.

Conclusion

If your car is riding a bit low to the ground, or you notice that the steering wheel or pedals are vibrating, it might be time to check your tires. Other signs include uneven wear on the tread and bulges or splits in the sidewall. You can use a tire gauge to check the pressure of your tires and add air if necessary.

It’s important to keep your tires properly inflated since underinflated tires can lead to decreased fuel efficiency and increased wear and tear.

Tire Air Pump How to Use

If you’ve ever been driving and had a tire go flat, you know how frustrating it can be. The good news is that if you have a tire air pump, you can easily fix the problem yourself. Here’s a quick guide on how to use a tire air pump:

Start by checking the pressure in your tires. If they’re low, use the air pump to add air until they’re at the correct level. Then, unscrew the cap from the valve stem on each tire.

Place the nozzle of the air pump over the valve stem and start pumping. Once the tire is inflated to the proper level, screw the cap back onto the valve stem.

If you’ve ever been stranded on the side of the road with a flat tire, you know how important it is to have a working air pump. But even if you haven’t had that experience, it’s still a good idea to know how to use one. After all, you never know when you might need it!

Here’s a quick guide on how to use a tire air pump:1. Make sure that the power switch is in the “off” position before plugging in the pump.2. Once plugged in, turn on the power switch and set the pressure gauge to your desired PSI reading.

3. Place the nozzle over the valve stem on your tire and press down firmly to create a seal.4. Begin pumping air into the tire until you reach your desired PSI reading. You may hear a hissing sound as air escapes from around the nozzle, but this is normal.

Just keep pumping until the noise stops.5. Once finished, remove the nozzle and replace the cap on your tire’s valve stem. Then, unplug the air pump and store it away for next time!

How to Inflate Car Tires at Home

If you’re like most people, you probably don’t think much about your car’s tires until there’s a problem. But keeping your tires properly inflated is actually one of the simplest and most effective ways to extend their life and improve your gas mileage. Here’s how to do it:

First, find out what the correct tire pressure is for your vehicle. This information can usually be found on a sticker inside the driver’s door frame or in the owner’s manual.Next, invest in a good quality air compressor.

You can find these at most auto parts stores or online. Be sure to get one that has an automatic shut-off feature so you don’t overinflate the tires.Now it’s time to start inflating!

Connect the air compressor to the tire valve and turn it on. The tire should start filling up slowly. Once it reaches the correct pressure, the compressor will automatically shut off.

Repeat this process for all four tires.And that’s all there is to it! Inflating your car tires regularly is a quick and easy way to keep them in top condition and improve your gas mileage.

How to Use Tire Air Pump at Gas Station

If you’re like most people, you probably don’t think much about your tires until something goes wrong. But did you know that properly inflated tires can save you money and improve your safety on the road? That’s why it’s important to know how to use a tire air pump at a gas station.

Here’s what you need to do:1. Find the right tire air pump for your car. There are two types of tire air pumps: those that work with your car’s cigarette lighter and those that plug into a standard 120-volt outlet.

If you’re not sure which type of pump you need, consult your car’s owner manual or ask a staff member at the gas station.2. Insert the air pump nozzle into the valve stem on your tire. Make sure that the nozzle is fully inserted; otherwise, air will escape and it will be harder to get an accurate reading from the pressure gauge.

3. Turn on the air pump and wait for it to reach its maximum pressure (usually around 60 psi). Once it reaches this point, stop inflating and remove the nozzle from the valve stem. Be careful not to overinflate your tires; too much pressure can cause them to burst.

4. Check the pressure gauge on the air pump to see how much air you’ve added to your tires. Compare this number with what is recommended in your car’s owner manual or on the placard inside your doorjamb (this is usually between 30 and 35 psi). If necessary, add more air until you reach the proper level of inflation.

How Much Air to Pump into Car Tires

If you’re like most people, you probably don’t think much about your car’s tires – until one goes flat. Then, all of a sudden, you have to think about how much air to pump into the tire.Most passenger car tires require between 30 and 35 PSI (pounds per square inch) of pressure.

Some trucks and SUVs may require more, up to 60 PSI. You can usually find the recommended tire pressure for your vehicle on a placard inside the driver’s door or in the owner’s manual.It’s important not to overinflate or underinflate your tires.

Overinflation can cause premature wear and make the ride less comfortable. Underinflation can lead to increased fuel consumption and reduced traction in wet weather conditions.To get an accurate reading of tire pressure, it’s best to check when the tires are cold (first thing in the morning is ideal).

Use a reliable tire gauge – digital ones are more accurate than analog – and check each tire individually. Add air as needed to reach the correct PSI level.

How Does a Tire Inflator Work

Inflating a tire is simple with a tire inflator. Most have a gauge to help you get the pressure just right. You’ll also find a valve stem cap remover on many models in case your valve stems are difficult to reach.

Here’s how it works:First, make sure the power cord is unplugged from the outlet. Then, attach the air hose to the chuck.

Next, screw the chuck onto the valve stem until it’s tight. Finally, plug in the power cord and turn on the switch. The inflator will automatically stop when it reaches the desired PSI reading on the gauge.

How to Put Air in a Tire

It is important to know how to put air in a tire, as this can be a lifesaving measure when you are on the road. There are two different ways that you can do this, and each has its own benefits. The first way is to use an air compressor.

This method is quick and easy, and it will give you a precise amount of air. However, it can be expensive to buy an air compressor, so this may not be the best option for everyone. The second way to put air in a tire is to use a hand pump.

This method is slower than using an air compressor, but it is much less expensive. You can also control the amount of air that you are putting into the tire better with this method.

Credit: www.monoprice.com

How Do I Pump Air into My Tires at a Gas Station?

If you’re like most people, you probably don’t think too much about your car’s tires. But if you want to keep your vehicle running safely and smoothly, it’s important to maintain them properly – and that includes keeping them inflated to the correct pressure.One way to do this is to use a air compressor at a gas station.

Here’s how it works:1. Park your car next to the air compressor and turn off the engine.2. Locate the valve stem on each tire – this is where you’ll be attaching the air hose.

3. Put the end of the air hose over the valve stem and make sure it’s snugly in place (you may need to unscrew the cap first).4. Turn on the air compressor and monitor the gauge as it fills up your tire with air. Stop when it reaches the recommended PSI for your tires (this information can be found in your owner’s manual or on a sticker inside your driver-side door).

How Do You Use a Gas Station Air Pump in a Car?

If your car has low tire pressure, you can use a gas station air pump to fill up the tires. Here’s how:1. Find an air pump at a gas station.

They are usually located near the gas pumps.2. Insert your car’s key into the air pump and turn it on.3. Put the nozzle of the air pump into one of your car’s tires and start pumping air into it until it reaches the desired pressure.

Make sure to check your car’s owner’s manual to know what the recommended tire pressure is for your vehicle.4. Repeat steps 2-3 for each of your car’s tires that need more air pressure.

How Do You Properly Inflate a Tire?