Tire Manufacturing Process Pdf

The tire manufacturing process begins with the mixing of raw materials to create rubber. Next, this rubber is vulcanized, or treated with heat and chemicals to make it stronger and more durable. The vulcanized rubber is then molded into shape and cured, or left to cool and harden.

Finally, the tires are inspected for defects and shipped to customers.

tire manufacturing process

Tire manufacturing is a complex process that involves several different stages. The first stage of the process is the mixing of raw materials. This includes rubber, carbon black, chemicals and other compounding ingredients.

The mixture is then placed into a mold where it is vulcanized, or cured. This curing process gives the tire its shape and strength. Once the tire has cooled, it is removed from the mold and trimmed to its final size.

Tyre Manufacturing Process Step by Step

The modern tyre is a complex engineering feat, and the process of manufacturing tyres is just as complicated. Here’s a step-by-step look at how tyres are made.1. The first step in the tyre manufacturing process is the compounding of the rubber.

This is done by mixing together various ingredients in large vats called Banbury mixers. The exact recipe for each type of tyre is a closely guarded secret, but common ingredients include natural and synthetic rubber, carbon black, sulfur, oils, and other chemicals.2. Once the rubber has been mixed together, it undergoes a vulcanization process to crosslink the molecules and make them stronger.

This process was invented by Charles Goodyear in 1839 and involves heating the rubber with sulphur at high temperatures.3. After vulcanization, the rubber is ready to be formed into tyres. To do this, it is first placed into large moulds where it takes on the shape of the desired tyre tread design.

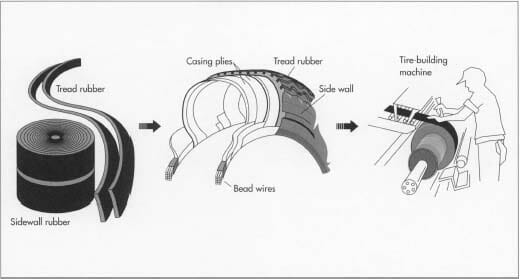

4 sidewalls are then added to form the complete tyre shape before it is cooled and removed from the moulds .5 Next ,the tyremakers will add reinforcement layers made from fabric or steel belting . These layers help to support the weight of the vehicle and protect against punctures .6 Finally , an inner liner made from another type of synthetic rubber is added to prevent air leaks .7 Once all these components have been put together ,the tyre is ready to be inflated and mounted on a wheel rim .8 Then It can finally be used on a car ,truck ,or bicycle!

Tyre Manufacturing Process Ppt

The process of manufacturing tyres is a complex one that involves multiple steps and procedures. Tyre manufacturers must adhere to strict quality standards to ensure that their products meet the needs of consumers. The following is a detailed overview of the tyre manufacturing process:

Raw Materials:

The first step in the tyre manufacturing process is sourcing the raw materials. natural rubber, synthetic rubber, fabric and steel wire are all required to make a tyre.

These materials are sourced from suppliers around the world and must meet the strictest quality standards.Compounding:

Once the raw materials have been sourced, they are sent to the compounding department where they are mixed together to create a compound.

This compound is then used to create tyres with specific properties such as strength, durability and resistance. Different compounds are used for different types of tyres such as passenger car tyres or truck tyres.Extrusion:

The next step in the process is extrusion where the compound is fed into an extruder machine where it is heated and formed into shape. The tyre tread and sidewall design is created at this stage. Extrusion machines can produce up to 10 tyres per minute!

Curing:

After extrusion, the newly formed tyres need to go through a curing process where they are placed in moulds and exposed to high temperatures for vulcanisation to occur. This makes the tyres stronger and more durable.

Curing takes place in large autoclaves which can hold hundreds of tyres at once. Once cured, the tyres are cooled down before moving on to the next stage of production.

Tyre Technology Books Pdf

When it comes to choosing the right tyres for your vehicle, you need to make sure that you have all the right information at your disposal. With so many different tyre manufacturers and types of tyres on the market, it can be difficult to know where to start. However, by reading a few key tyre technology books, you can quickly get up to speed on everything that you need to know.

One of the best tyre technology books available is “Tyre Technology: Fundamentals, Materials and Manufacturing Processes”. This book provides a comprehensive overview of all aspects of tyre technology, from the basics of how tyres are made through to advanced manufacturing processes. It also includes detailed information on materials used in tyre construction, as well as performance characteristics of different types of tyres.

If you want to learn everything there is to know about tyres, this is the book for you.Another excellent resource for learning about tyre technology is “The Tyre Technology Handbook”. This book contains a wealth of information on all aspects of tyre design, manufacture and performance.

It includes chapters on topics such as tread patterns, sidewall design and rolling resistance, making it an essential read for anyone involved in the development or use of tyres.If you’re looking for more specific information on a particular type of tyre, there are also many specialist books available. For example, if you’re interested in winter tyres then “Winter Tyres: Technology and Application” by Klaus Zinken would be an excellent choice.

This book provides a detailed analysis of winter tyre performance characteristics and discusses how they can be optimised for use in various conditions.Whether you’re a car enthusiast or simply someone who wants to make sure their vehicle has the best possible tyres fitted, reading one or more of these tye technology books is essential. By doing so, you’ll gain a much better understanding of this complex topic and be able to choose the perfect tyres for your needs.

Tyre Manufacturing Plant Project Report Pdf

Are you planning to start a tyre manufacturing plant? If yes, then you must prepare a detailed project report. In this post, we will provide you with all the information that you need to know about preparing a tyre manufacturing plant project report pdf.

The first step is to gather all the necessary data and information. You will need to research the market, the competition, and the potential customer base. It is important to have a clear understanding of these factors before you start your project.

Next, you will need to create a business plan. This should include your financial projections, marketing strategies, and production plans. Make sure that your business plan is realistic and achievable.

Once you have your business plan ready, it’s time to start working on your project report. This document should include all the details of your project, including the costs involved, timelines, risks, and benefits. Make sure that you include everything in your report so that investors can make an informed decision about whether or not to invest in your project.

If you follow these steps carefully, you will be able to create a successful tyre manufacturing plant project report pdf that will help you get the funding you need to get started on your new business venture!

Tyre Curing Process Pdf

When it comes to tyres, the curing process is just as important as any other stage in the manufacturing process. In fact, it’s often said that tyres are only as good as their cure. So what exactly is tyre curing and how does it impact the quality of your tyres?

Tyre curing is the process of vulcanising rubber. This involves adding sulphur or another vulcanising agent to the rubber mix and then heating it to create cross-links between the polymer chains. This makes the rubber stronger and more resistant to heat and wear.

It also gives tyres their distinctive ‘bouncy’ feel.The type of vulcanising agent used, and the temperature and time at which the vulcanisation reaction takes place, all have an impact on the properties of the finished tyre. For example, using a higher temperature will result in a harder tyre with less grip, while a longer vulcanisation time will produce a softer tyre with better grip.

One of the most important things to get right during tyre curing is ensuring that there are no voids or bubbles in the rubber mix. These can cause problems later on down the line, such as premature tread wear or even blowouts. To avoid this, manufacturers use specialised equipment that applies pressure and vacuum during cure cycles to remove any air pockets from within the rubber.

Once cured, tyres are cooled before being inspected for flaws. Any tyres that don’t meet standards are rejected and recycled back into new ones. The rest are sent off for further processing (such as fitting them with treads) before being shipped out to customers all over the world!

Credit: sickusablog.com

What is the Manufacturing Process of a Tire?

In order to manufacture a tire, several different materials are needed. These materials include rubber, carbon black, synthetic rubber, and other chemicals. The first step in the manufacturing process is to create the “green tire.”

The green tire is made by combining all of the necessary ingredients in a large mixer. Once the ingredients are mixed together, they are vulcanized (or cured). Vulcanization is a process where the rubber is heated and then cooled in order to make it stronger.

After the green tires are vulcanized, they are then placed on a machine that will shape them into their final form. Once they have been shaped, they are put into an oven where they will be dried. After they come out of the oven, any excess material is trimmed off and then the tires undergo a final inspection before being shipped out.

What are the 4 Major Materials That Tires are Made Of?

Tires are made of four major materials: rubber, steel, wire, and fabric. Each material has its own unique properties that make it ideal for tire construction.Rubber is the primary material in tires.

It provides good traction and absorbs shocks to protect the inner structure of the tire. Steel reinforcement gives tires strength and durability. Wire helps keep the tire inflated and also reinforces the sidewalls of the tire.

Fabric helps hold everything together and gives the tire its shape.

What is the Raw Material for Making Tyres?

There are a few different raw materials that can be used to make tyres, but the most common is rubber. This is because rubber has a number of properties that make it ideal for use in tyres. It is flexible, which helps to absorb shocks and protect the vehicle from bumps in the road.

It is also strong and durable, meaning that it can withstand the high temperatures and pressures that are generated when a vehicle is in motion. Rubber also has good grip properties, helping to keep the vehicle stable on the road.

Which Chemical is Used in Tire?

The main chemical used in tire manufacturing is rubber. There are many different types of rubber, but the most common type used in tires is synthetic rubber. This is because it has superior strength and durability compared to natural rubber.

Other chemicals that are used in tire manufacturing include carbon black and sulfur. These two materials are added to improve the strength and flexibility of the tire.

Conclusion

Tire manufacturing is a complex process that involves a variety of chemicals and materials. The end product is a rubber tire that is strong and durable. There are several steps involved in the tire manufacturing process, including vulcanization, molding, and finishing.

Each step requires different machinery and techniques. The finished product must meet strict quality standards before it can be sold to consumers.