Author Archives: David V. Williamson

- Home

- Author's Archive:

How To Tell If A Wheel Bearing Is Bad While Driving

There are a few things you can pay attention to while driving that may indicate your wheel bearing is going bad. If you hear a grinding noise coming from the wheel area, this is likely the first sign that something is wrong. The noise will usually get louder as you drive faster.

You may also feel a vibration in the steering wheel or seat that gets worse the faster you drive. If you notice either of these issues, it’s important to have your vehicle checked out as soon as possible to avoid further damage.

- Pay attention to any strange noises coming from the wheels while driving

- If you hear a grinding or growling noise, it could be a sign that the wheel bearing is going bad

- Also, pay attention to how the car feels while driving

- If the car starts to feel like it is wobbling or shaking, this could also be a sign of a bad wheel bearing

- If you suspect that the wheel bearing is going bad, it is best to have it checked out by a mechanic as soon as possible

- They will be able to tell for sure and can make the necessary repairs

How do you diagnose a bad wheel bearing while driving?

If you’re driving and you notice that your car is making a humming noise, it’s possible that your wheel bearing is going bad. Here are a few other signs that your wheel bearing might be failing:– Your car feels like it’s shaking or vibrating

– The steering wheel feels loose

– The brake pedal feels spongyIf you notice any of these symptoms, it’s important to have your car checked out by a mechanic as soon as possible.

A failing wheel bearing can cause serious damage to your car if it’s not fixed, so don’t ignore the signs!

What does it feel like driving with a bad wheel bearing?

If you hear a grinding noise coming from your car while you’re driving, it’s possible that your wheel bearings are going bad. Here are a few other signs that your wheel bearings may be failing:– Your car starts to pull to one side while you’re driving

– Your steering feels loose or wobbles

– You feel a vibration in your steering wheel or seat

– Your car’s brakes feel less effective

If you notice any of these signs, it’s important to get your car checked out by a mechanic as soon as possible. Wheel bearings are an important part of your car’s suspension, and if they fail, it can be very dangerous.

How long can you drive with a bad wheel bearing?

If you’re wondering how to tell if a wheel bearing is bad while driving, there are a few signs to look out for. You may notice a grinding noise coming from the affected wheel, or the steering wheel may shake when driving at high speeds. There may also be a feeling of looseness in the affected wheel.

If you notice any of these symptoms, it’s important to have the wheel bearing checked out by a mechanic as soon as possible.

Wheel bearing noise

If you’re driving and you suspect that a wheel bearing is going bad, there are a few things you can look for. First, listen for a humming or grinding noise coming from the wheel area. This is a classic sign of a bad wheel bearing.

Second, feel for any vibration in the steering wheel or through the seat. This can be a sign that the bearing is not spinning smoothly.Third, look at the condition of the tire.

If the tire is starting to show signs of wear on one side more than the other, it could be because the bearing is causing the wheel to wobble.If you notice any of these signs, it’s important to get the bearing checked out as soon as possible. A bad wheel bearing can cause all sorts of problems, from decreased fuel economy to complete loss of control of the vehicle.

So don’t take any chances – if you think there’s a problem, get it checked out!

Front wheel bearing noise symptoms

If you’re driving and you notice that your car starts to shake, vibrate, or make strange noises, it could be a sign that your wheel bearing is going bad. Here are a few other symptoms to watch out for:– Your car takes longer to stop than usual

– You feel a pulsing sensation when you brake– Your steering feels loose or wobbles– Your car pulls to one side when you’re driving

If you notice any of these things, it’s important to get your car checked out by a mechanic as soon as possible. A bad wheel bearing can cause serious damage to your car if it’s not fixed, so don’t delay in getting it checked out!

What happens if a wheel bearing fails while driving

If you’re driving and you suspect that a wheel bearing may be failing, there are a few tell-tale signs to look out for. First, listen for any unusual noise coming from the affected wheel. A bad wheel bearing will often make a grinding or growling noise that will be most noticeable when driving at lower speeds.

Additionally, you may feel vibration or shaking in the steering wheel or seat that corresponds to the affected wheel.If you notice either of these symptoms while driving, it’s important to get your vehicle to a mechanic as soon as possible. A failing wheel bearing can cause serious damage to your car if it is not addressed, so it’s best not to take any chances.

Bad wheel bearing symptoms

If you’re driving and you notice that your car is making a loud, grinding noise, it’s possible that you have a bad wheel bearing. Here are a few other signs that your wheel bearing might be going bad:1. Your car vibrates when you’re driving at high speeds.

2. Your steering feels loose or wobbles when you turn.3. Your car pulls to one side when you’re driving.If you notice any of these symptoms, it’s important to get your car checked out by a mechanic as soon as possible.

A bad wheel bearing can cause serious damage to your car if it’s not fixed, so don’t delay in getting it checked out!

Wheel bearing noise when turning left

If you’re driving and you think your wheel bearing might be going bad, there are a few things you can look for. First, see if the steering wheel is vibrating. This is usually a sign that something is wrong with the front wheel bearings.

Second, listen for a humming noise coming from the wheel area. This noise is caused by the bearings spinning at high speeds and can be a sign that they’re starting to wear down. Finally, check to see if your car is pulling to one side.

This can be a sign that the bearings are not properly aligned. If you notice any of these things, it’s best to take your car to a mechanic and have them check it out.

Wheel bearing noise diagnosis

If you notice any unusual noise or vibration coming from your wheels while driving, it could be a sign that your wheel bearings are going bad. Here are a few other things to look for:– If your car starts to pull to one side while driving, this could be a sign that a wheel bearing is damaged and not working properly.

– If you hear a grinding noise coming from your wheels, this is another sign that your wheel bearings may be damaged.– If you feel a vibration in your steering wheel or seat, this could also be a sign of damaged wheel bearings.If you notice any of these signs, it’s important to have your car checked out by a mechanic as soon as possible.

Wheel bearings are an important part of your car’s suspension and if they are damaged, it can cause serious problems.

How long will a wheel bearing last after it starts making noise

If you’re driving and you suspect that a wheel bearing is going bad, there are a few things you can look for to confirm your suspicions. First, listen for any strange noises coming from the affected wheel. A bad wheel bearing will often make a grinding or growling noise that will get louder as you accelerate.

Additionally, you may feel a vibration in the steering wheel or seat that gets worse as you drive faster.If you notice either of these signs, it’s best to get your car checked out by a mechanic as soon as possible. A bad wheel bearing can cause serious damage to your car if it’s not fixed, so it’s best not to take any chances.

How to stop wheel bearing noise

If you’re driving and you notice that your steering wheel is starting to vibrate, or that your car is making a humming noise, there’s a good chance that your wheel bearing is going bad. Here are a few other signs that your wheel bearing might be failing:1. Your car starts to pull to one side while driving

2. Your steering wheel becomes harder to turn3. Your car vibrates at high speeds4. You hear a grinding noise coming from your wheels

If you notice any of these signs, it’s important to have your car checked out by a mechanic as soon as possible. A failed wheel bearing can be very dangerous and can cause serious damage to your car.

Conclusion

If you’re driving and you suspect that a wheel bearing is going bad, there are a few signs you can look for. The first is a humming noise that gets louder as you accelerate. You may also feel a vibration in the steering wheel or seat.

Additionally, the car may pull to one side or the other. If you notice any of these signs, it’s important to get the car checked out by a mechanic as soon as possible.

How To Reset Tire Pressure Sensor Chevy Silverado 2008

If your Chevy Silverado’s tire pressure sensor needs to be reset, there are a few simple steps you can follow. First, locate the tire pressure sensor, which is usually located on the inside of the wheel well. Next, use a tire pressure gauge to check the tire pressure and inflate the tires to the recommended pressure if necessary.

Finally, use a reset tool to clear the tire pressure sensor’s memory.

- Park your Chevy Silverado on a flat surface and turn off the engine

- Locate the tire pressure sensor on the affected tire

- Use a tire pressure gauge to check the current air pressure in the tire

- Use a tire iron to loosen the lug nuts on the affected tire

- Remove the tire from the Silverado

- Find the reset button on the tire pressure sensor

- Use a small object, such as a paperclip, to press and hold the reset button for five seconds

- Re-install the tire on the Silverado and tighten the lug nuts

- Turn on the engine and check the tire pressure sensor to make sure it is reset

How do you reset the tire pressure sensor on a Chevy Silverado?

If your Chevy Silverado’s tire pressure sensor needs resetting, there are a few different ways you can do it. One way is to use a special tool called a tire pressure sensor reset tool. This tool can be found at most auto parts stores.

Another way is to use a handheld OBD-II scanner. This scanner will read the tire pressure sensor data and then allow you to reset the sensor.

Where is the TPMS reset button?

If you have a Chevy Silverado from 2008, you may be wondering how to reset the tire pressure sensor. Fortunately, it’s a pretty easy process. Here’s what you need to do:

1. Start by turning on your ignition.2. Then, press and hold the “Set/Reset” button on your instrument panel for about 5 seconds.3. After that, press the “Tire Pressure” button on your instrument panel.

4. Finally, use the arrow buttons to adjust the tire pressure to the desired level.That’s all there is to it! Resetting the tire pressure sensor on your Chevy Silverado is a quick and easy process.

How do you reset the tire monitor on a 2007 Chevy Silverado?

If your Chevy Silverado’s tire pressure sensor needs to be reset, there are a few things you’ll need to do. First, you’ll need to find the reset button on the sensor. This is usually located on the back of the sensor.

Once you’ve found the reset button, press and hold it for a few seconds.Next, you’ll need to turn on your Silverado’s ignition. Once the ignition is on, press and hold the reset button on the sensor for a few more seconds.

After a few seconds, the sensor will be reset and you can release the button.If your Silverado is equipped with a tire pressure monitoring system, you may need to reset the system after you reset the sensor. To do this, simply press and hold the reset button on the system for a few seconds.

That’s all there is to resetting your Chevy Silverado’s tire pressure sensor!

How do you reset the tire pressure light on a 2008 GMC Sierra?

If you have a Chevy Silverado 2008, you may be wondering how to reset the tire pressure sensor. This is actually a pretty simple process, and it can be done in just a few minutes. Here’s what you need to do:

1. First, locate the tire pressure sensor on your Silverado. It will be located on the inside of the wheel well, near the tire.2. Next, use a tire pressure gauge to check the pressure in all of your tires.

Make sure that they are all inflated to the proper level.3. Once you have verified that the tires are all properly inflated, you can go ahead and reset the tire pressure sensor. To do this, simply press and hold the “Reset” button on the sensor for about 5 seconds.

4. That’s it! You’ve now successfully reset the tire pressure sensor on your Chevy Silverado.

2008 silverado tpms reset without tool

If your Chevy Silverado’s tire pressure sensor needs to be reset, there are a few things you’ll need to do. First, you’ll need to find the reset button. This is usually located on the dash near the speedometer.

Once you’ve found the reset button, press and hold it for about five seconds. Next, turn the ignition to the “on” position without starting the engine. Again, press and hold the reset button for about five seconds.

Finally, start the engine and drive around for a bit to see if the light comes back on. If it does, repeat the process.

How to turn off service tire monitor system light chevy silverado

If you have a 2008 Chevy Silverado and need to reset the tire pressure sensor, here are the steps you’ll need to follow.1. Start by removing the tire pressure sensor from the tire.2. Next, use a tire pressure gauge to check the pressure of the tire.

3. Once you know the pressure of the tire, use a tire pressure sensor reset tool to reset the sensor.4. Finally, reinstall the tire pressure sensor and you’re all set!

How to reset tire pressure sensor chevy silverado 2009

If your Chevy Silverado’s tire pressure sensor needs to be reset, follow these steps:1. Park your Silverado in a safe, level location.2. Turn the ignition to the “On” position, but do not start the engine.

3. Press and release the “Trip/Odometer” button until the message “TPMS Learn Mode Active” appears on the driver information center.4. Press and hold the “Set/Reset” button for approximately five seconds. The message “TPMS Relearn Complete” will appear when the process is finished.

5. You can now start your engine and drive as usual.

2008 chevy silverado tpms problems

If you have a 2008 Chevy Silverado, you may find that the tire pressure sensor needs to be reset from time to time. Here’s how to do it:1. Start by turning on the ignition, but do not start the engine.

2. Press and hold the trip odometer reset button.3. While holding the trip odometer reset button, turn the key to the “run” position.4. Continue to hold the trip odometer reset button until the tire pressure sensor light on the dash goes out.

5. Release the trip odometer reset button and you’re done!

2008 silverado tpms sensor

If your Chevy Silverado’s tire pressure sensor needs to be reset, there are a few things you’ll need to do. First, you’ll need to find the tire pressure sensor. This is usually located on the inside of the tire, near the rim.

Once you’ve found it, you’ll need to use a tire pressure gauge to check the pressure in all four tires. If any of the tires are low, you’ll need to add air until they’re all at the correct pressure.Once the tires are all inflated to the correct pressure, you’ll need to use a reset tool to reset the tire pressure sensor.

This can usually be found at your local auto parts store. Once you have the reset tool, follow the instructions that come with it to reset the sensor.That’s all there is to it!

After following these steps, your Chevy Silverado’s tire pressure sensor should be reset and working properly.

2010 silverado tire pressure sensor reset

If your Chevy Silverado’s tire pressure sensor needs to be reset, there are a few simple steps you can follow to do so. First, locate the tire pressure sensor, which is usually located on the inside of the wheel well. Then, use a tire pressure gauge to check the pressure in all of your tires and adjust accordingly.

Finally, use a reset tool or your Silverado’s computer to reset the tire pressure sensor.

How to reset tire pressure sensor chevy silverado 2020

If your Chevy Silverado’s tire pressure sensor needs to be reset, there are a few things you’ll need to do. First, you’ll need to locate the tire pressure sensor, which is usually located on the inside of the wheel well. Once you’ve found the tire pressure sensor, you’ll need to use a tire pressure gauge to check the tire pressure and make sure it’s at the correct level.

If the tire pressure is too low, you can add air to the tire until it reaches the correct level. Once the tire pressure is at the correct level, you can reset the tire pressure sensor by press and holding the reset button for about 5 seconds.

How to reset tire pressure sensor chevy silverado 2011

If your Chevy Silverado’s tire pressure sensor needs to be reset, there are a few things you’ll need to do. First, you’ll need to find the tire pressure sensor, which is located on the inside of the tire. Once you’ve located the sensor, you’ll need to use a tire pressure gauge to reset the sensor.

To do this, simply press the reset button on the tire pressure gauge.Once the sensor has been reset, you’ll need to check the tire pressure to make sure it is at the correct level. You can do this by using a tire pressure gauge or by checking the tire pressure on the tire itself.

If the tire pressure is too low, you’ll need to add air to the tire. If the tire pressure is too high, you’ll need to release some air from the tire.

Conclusion

If your Chevy Silverado’s tire pressure sensor needs to be reset, there’s a simple way to do it. Just follow these steps:1. Make sure the Silverado is turned off.

2. Locate the tire pressure sensor, which is usually located on the driver’s side door.3. Press and hold the reset button on the sensor for about 5 seconds.4. You should see a light on the sensor flash, indicating that the reset is complete.

5. Start up the Silverado and drive it for a few miles to make sure the sensor is working properly.If you have any questions about resetting the tire pressure sensor on your Chevy Silverado, be sure to consult your owner’s manual or a qualified mechanic.

How To Reset Tire Pressure On Honda Civic 2015

If your Honda Civic’s tire pressure monitoring system (TPMS) light illuminates, it means that the pressure in one or more of your tires is low. You can reset the system by adding air to your tires or, if your tires are already inflated to the proper pressure, by driving for a few miles. Here’s how to do both:

To reset the system by adding air to your tires:1. Park your Civic in a safe place and turn off the engine.2. Locate the tire that is low on pressure and remove the valve cap.

3. Press the valve stem firmly to release any air that may be left in the tire.4. Connect an air hose to the valve stem and inflate the tire to the recommended pressure.5. Replace the valve cap and repeat the process for each tire that is low on pressure.

- Park your Honda Civic on a level surface and turn off the engine

- Locate the tire pressure monitoring system (TPMS) reset button, which is usually located on the dash or center console

- Press and hold the TPMS reset button for approximately five seconds

- The TPMS light will flash to indicate that the system has been reset

- Check the tire pressure in all four tires and inflate or deflate as needed to achieve the recommended pressure

Where is the TPMS button on a 2015 Honda Civic?

If you need to reset the tire pressure on your Honda Civic 2015, there are a few things you need to do. First, find the tire pressure sensor on the driver’s side door. Second, use a tire pressure gauge to check the pressure in all four tires.

Third, use the Honda Civic 2015 Tire Pressure Reset Tool to reset the pressure in the tires. Finally, drive the car for a few miles to make sure the pressure is reset.

How do you reset the tire pressure sensor on a Honda Civic?

If your Honda Civic’s tire pressure monitoring system (TPMS) light is on, it means that one or more of your tires is significantly under-inflated. Inflating your tires to the correct pressure is important for both safety and fuel efficiency.To reset the TPMS light on your Honda Civic, start by finding the recommended tire pressure for your vehicle.

This information can be found in your owner’s manual or on a sticker inside the driver’s door. Once you know the correct tire pressure, use a tire pressure gauge to check the pressure of all four tires. If any of the tires are below the recommended pressure, use a air compressor or tire inflator to inflate them to the proper level.

Once all four tires are inflated to the correct pressure, the TPMS light should turn off automatically.

How do you reset the tire pressure sensor on a 2015?

If you need to reset the tire pressure on your Honda Civic 2015, there are a few things you need to do. First, find the reset button on the dash. It should be located near the odometer.

Once you’ve found the reset button, press and hold it for about three seconds.Next, turn the ignition to the “on” position without starting the engine. Once the ignition is on, press and release the reset button.

The tire pressure light on the dash should now be reset.If you have a Honda Civic with a tire pressure monitoring system (TPMS), there is a different process for resetting the system. For Civic models with TPMS, you need to use a scan tool to reset the system.

Consult your owner’s manual or a Honda dealer for more information on resetting the TPMS on your specific model.

Does 2015 Honda Civic have TPMS?

If your Honda Civic has tire pressure sensing valves, the process for resetting the tire pressure monitor is different than if it doesn’t. If your Civic is equipped with tire pressure sensing valves, follow these steps to reset the system:1. Start the engine and turn on the tire pressure monitor system.

2. Drive the vehicle for a few minutes to allow the system to stabilize.3. Stop the vehicle in a safe location and turn off the engine.4. Remove the cap from the tire pressure sensor valve.

5. Use a tire pressure gauge to check the pressure in all four tires.6. Adjust the pressure in each tire to the recommended level.7. Replace the cap on the tire pressure sensor valve.

8. Start the engine and turn off the tire pressure monitor system.9. Drive the vehicle for a few minutes to allow the system to recalibrate.

Reset tire pressure honda civic 2016

If you have a newer model Honda Civic (2015 or newer), then resetting your tire pressure is easy. All you need is the Honda Tire Pressure Monitoring System (TPMS) reset button. This button is located on the dash, near the steering wheel.

To reset your tire pressure, simply press and hold the TPMS reset button for about 5 seconds. The system will then automatically adjust the pressure in your tires to the recommended levels.If you have an older model Civic (2014 or older), then you’ll need to use a tire gauge to manually adjust the pressure in your tires.

First, find the recommended tire pressure for your vehicle in the owner’s manual.Then, use a tire gauge to check the pressure in each of your tires. If the pressure in any tire is below the recommended level, use a tire pump to add air until the pressure is at the recommended level.

That’s all there is to it!

How to reset tire pressure on honda civic 2017

If you have a Honda Civic from 2015 or newer, you may be wondering how to reset the tire pressure. The process is actually quite simple. Here’s what you need to do:

1. Park your Civic and turn off the engine.2. Locate the tire pressure sensor, which is located on the driver’s side near the door.3. Use a small object, such as a pen or paperclip, to press and hold the reset button for about 5 seconds.

4. Start the engine and drive around for a few minutes to allow the system to recalibrate.That’s all there is to it! By following these steps, you can easily reset the tire pressure on your Honda Civic.

How to reset tire pressure on honda civic 2019

If your Honda Civic has low tire pressure, you can reset the tire pressure sensor by following these steps:1. Locate the tire pressure sensor reset button. This is usually located on thedashboard, near the steering wheel.

2. Press and hold the reset button for five seconds.3. Release the reset button.4. Start the engine.

5. Drive the vehicle for a few miles to allow the tire pressure sensor to re-calibrate.

2015 honda civic tire pressure light keeps coming on

If you’re like most people, you probably don’t think about your car’s tire pressure unless there’s a problem. But did you know that properly inflated tires can save you money, improve your gas mileage, and extend the life of your tires?Unfortunately, it’s not always easy to keep track of your tire pressure.

That’s why it’s important to know how to reset the tire pressure on your Honda Civic.Here’s what you need to do:1. Use a tire pressure gauge to check the pressure of all four tires.

2. If any of the tires are low, remove the valve cap and use a tire inflator to add air until the tire is inflated to the proper pressure.3. Once all four tires are properly inflated, use the tire pressure gauge to check the pressure of the spare tire.4. If the spare tire is low, add air until it is inflated to the proper pressure.

Reset tire pressure honda civic 2021

If you have a 2015 Honda Civic, you may be wondering how to reset the tire pressure. Here’s a quick guide to help you out.Start by turning on your engine and pressing the “info” button on your dash.

Then, use the arrow keys to scroll over to the “vehicle” tab. From there, scroll down to “tire pressure” and press enter.Now, you should see a screen that shows the current pressure in each of your tires.

If any of the tires are low, you’ll need to add air. To do this, find the tire that’s low on pressure and press the “set” button.Enter the recommended pressure for that tire and press enter.

The tire will now be inflated to the proper pressure. Repeat this process for each tire that’s low on pressure.Once all of your tires are properly inflated, you can exit the menu by pressing the “info” button again.

Reset tire pressure honda civic 2020

If you’re like most people, you probably don’t think much about your car’s tire pressure. But if you’re driving a Honda Civic, it’s important to keep an eye on it. The 2015 Honda Civic has a Tire Pressure Monitoring System (TPMS) that alerts you when the pressure in one or more of your tires is low.

If the TPMS light comes on, it means that the pressure in one or more of your tires is below the recommended level. To reset the system, you’ll need to add air to your tires until the light goes off.Here’s how to do it:

1. Park your car in a safe place and turn off the engine.2. Locate the tire pressure sensor (it looks like a small black box) on each tire.3. Use a tire pressure gauge to check the pressure in each tire.

How to check tire pressure honda civic 2015

If your Honda Civic has low tire pressure, you can reset the tire pressure sensor by following these steps:1. Park your Honda Civic in a safe place and turn off the engine.2. Locate the tire pressure sensor reset button.

This is usually located on the dash near the steering wheel.3. Press and hold the reset button for about 5 seconds.4. Start the engine and drive around for a few minutes to allow the sensor to calibrate.

5. Check the tire pressure to make sure it is at the correct level.

2014 honda civic tpms reset

If you need to reset the tire pressure on your Honda Civic 2015, there are a few things you need to do. First, find the tire pressure sensor on the driver’s side door. Second, use a small flat-head screwdriver to press and hold the reset button for three seconds.

Finally, turn the screwdriver counterclockwise to release the button.

Conclusion

If your Honda Civic’s tire pressure light is on, it’s time to reset the tire pressure sensors. Here’s how to do it:1. Park your Civic on level ground and turn off the engine.

2. Locate the tire pressure sensor reset button. It’s usually on the dash, near the steering wheel.3. Press and hold the reset button for about 5 seconds.

4. Start the engine and drive for a few miles. The tire pressure light should go off.If the tire pressure light doesn’t go off, or if it comes back on, there may be a problem with the tire pressure sensors or the tire pressure sensor system.

How To Reset Tire Pressure Monitoring System?

If your car has a tire pressure monitoring system (TPMS), you’ll need to know how to reset it when you get new tires or swap out your winter tires for summer ones. Fortunately, it’s a pretty easy process. Here’s how to do it.

If your car has a tire pressure monitoring system (TPMS), you may need to reset it from time to time. There are a few different reasons why you might need to reset your TPMS, but the most common is after you’ve made a tire pressure adjustment. Here’s how to reset your TPMS:

1. Park your car in a safe, level spot.

2. Locate the TPMS reset button. This is usually located on the dash, near the steering wheel.

3. Press and hold the reset button for about 5 seconds.

4. Start the engine and drive around for a few minutes to allow the system to recalibrate. If your TPMS light is still on after resetting, there may be a problem with the system and you should have it checked out by a professional.

Can I reset tire pressure monitoring system?

If your car is equipped with a Tire Pressure Monitoring System (TPMS), you will need to reset the system when you get new tires or change your tire size.

Here’s how to do it:

1. Park your car in a safe location and turn off the engine.

2. Locate the TPMS reset button. This is usually located on the dash or near the steering wheel.

3. Press and hold the reset button for about 20 seconds.

4. Start the car and drive around for a few miles to allow the system to recalibrate.

5. That’s it! Your TPMS is now reset and ready to go.

Can you relearn TPMS without tool?

If your tire pressure monitoring system (TPMS) light is on, it means that your tires are low on air and you need to add air to them. You can usually do this yourself by using a air compressor or by going to a gas station that has an air pump. Once you’ve added air to your tires, you’ll need to reset the TPMS system so that the light will turn off.

To do this, find the TPMS reset button on your dash. It’s usually located near the steering wheel. Once you’ve found the button, press and hold it for about 30 seconds.

The light should turn off after a few seconds, indicating that the system has been reset.

Where is my TPMS reset button?

If your Tire Pressure Monitoring System (TPMS) light is on, it means that the pressure in one or more of your tires is low. You can often reset the light by adding air to the tires. However, if the light is on and you know that the tire pressure is fine, then there may be a problem with the TPMS itself.

In this case, you’ll need to reset the system. Here’s how to reset your TPMS:

1. Add air to your tires if needed. The TPMS light will often come on when the pressure in one or more tires is low. You can often reset the light by simply adding air to the tires.

2. Check the tire pressure with a gauge. Once you’ve added air to the tires, use a tire pressure gauge to check the pressure in each tire. Make sure that the pressure in each tire is at the correct level.

3. Find the TPMS reset button.

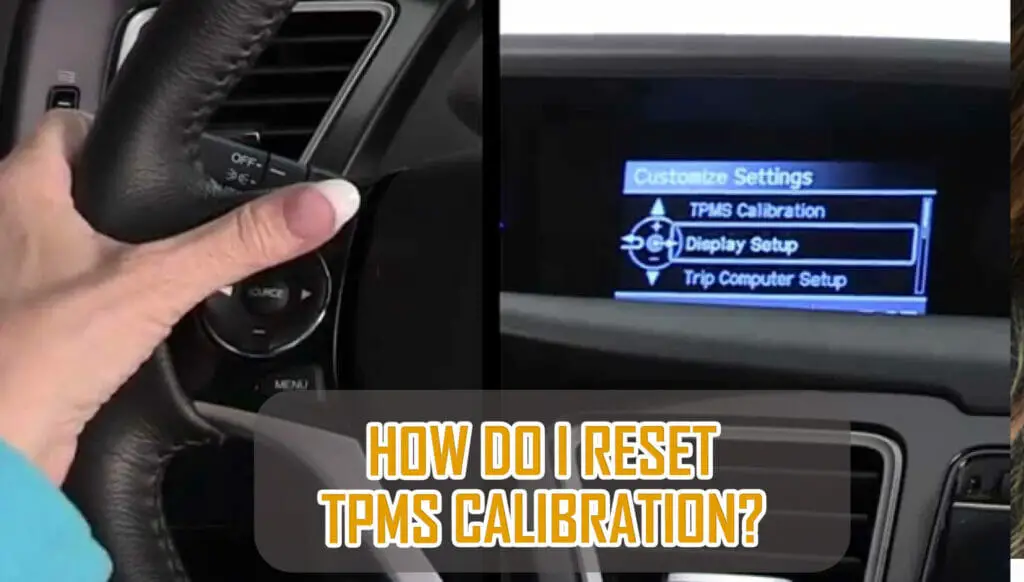

How do I reset TPMS calibration?

If your Tire Pressure Monitoring System (TPMS) light is on, it means that one or more of your tires is low on air. You’ll need to add air to your tires to bring them up to the recommended level. Once you’ve done that, you’ll need to reset your TPMS.

There are two ways to reset your TPMS:

1. The first way is to use your car’s onboard computer. Consult your owner’s manual to find the specific steps for your vehicle.

2. The second way is to use a TPMS reset tool. These tools are available at most auto parts stores. Once you’ve reset your TPMS, the light on your dash should go off.

If it doesn’t, you may have a problem with your TPMS sensors or system. Consult your owner’s manual or take your car to a qualified technician to have it checked out.

Where is the tpms reset button

If your vehicle has a tire pressure monitoring system (TPMS), you’ll need to know how to reset it. Otherwise, you’ll get false readings, and your vehicle won’t be able to properly monitor your tires.

Here’s a step-by-step guide on how to reset your TPMS:

1. Park your vehicle in a safe location and turn off the engine.

2. Locate the TPMS reset button. This is usually located on the dash or near the steering wheel.

3. Press and hold the reset button for a few seconds.

4. Start your engine and drive around for a few minutes to allow the system to recalibrate. If you’re still having trouble resetting your TPMS, consult your vehicle’s owner’s manual for further instructions.

How to reset the tire pressure sensor

If your car has a tire pressure monitoring system (TPMS), you may need to reset it from time to time. The TPMS is a feature that warns you when one or more of your tires are low on air, and it can be a valuable tool for keeping your car running safely. There are a few reasons why you might need to reset your TPMS.

If you get new tires, they may not have the right sensors for your TPMS, so you’ll need to reset the system to match the new tires. You may also need to reset the system if you get a flat tire and have to put on a spare. Whatever the reason, resetting your TPMS is a pretty easy process.

Here’s how to do it: 1. Start with your car’s ignition off. 2. Locate the TPMS reset button.

This is usually located on the dash, near the steering wheel.

Why is my tire pressure light on when my tires are fine

If your Tire Pressure Monitoring System (TPMS) light is on, it means that one or more of your tires is low on air. You can easily reset the system by following these simple steps:

1. Find the reset button. This is usually located on the dash, near the steering wheel.

2. Press and hold the reset button for a few seconds.

3. Start the engine and drive around for a few minutes.

4. The TPMS light should now be off. If your TPMS light doesn’t turn off after following these steps, it could mean that there is a problem with the system itself, and you should take your car to a mechanic to have it checked out.

Toyota tire pressure sensor reset

If your tire pressure monitoring system (TPMS) light is on, it means that one or more of your tires is low on air. You’ll need to add air to your tires to reset the TPMS. To reset your TPMS:

1. Add air to your tires. Check your owner’s manual to find out how much air to add.

2. Drive your car for a few miles. The TPMS light should go off once the tire pressure is back to normal. If the TPMS light doesn’t go off after you’ve added air to your tires, you may need to have your TPMS system checked by a mechanic.

Honda civic tire pressure light keeps coming on

If your tire pressure monitoring system (TPMS) light is on, it means that one or more of your tires is low on air. To reset the system, you’ll need to add air to your tires until the light goes off. There are two ways to do this:

1. Use a tire gauge to check the air pressure in each tire and add air as needed.

2. Drive your car for a few miles. The TPMS light will usually go off once the tires have warmed up and the air pressure has increased.

If you’re still having trouble, consult your car’s owner’s manual or take it to a mechanic.

Genesis g70 tire pressure reset

If your tire pressure monitoring system (TPMS) light is on, it means that one or more of your tires is low on air. You can typically find the specific tire that is low by looking at the corresponding light on your dash. Once you know which tire is low, use a tire gauge to check the pressure.

If the pressure is below the recommended level, add air until it reaches the proper level. If your TPMS light is on and you can’t find the specific tire that is low, it’s possible that the TPMS sensor is malfunctioning. In this case, you’ll need to reset the system.

The specific method for resetting your TPMS will vary depending on your vehicle, so consult your owner’s manual. In most cases, though, you can reset the system by driving at speeds above 25 mph for 10 minutes or so. Once the system is reset, the TPMS light should turn off.

Honda accord low tire pressure light on but tires are fine

If you have a tire pressure monitoring system (TPMS) in your vehicle, you may be wondering how to reset it. Depending on the type of TPMS you have, the process for resetting it may vary. Here are a few tips on how to reset your TPMS:

If you have a direct TPMS, the process for resetting it is usually pretty simple. All you need to do is re-learn the sensor IDs. This can usually be done by following the instructions in your owner’s manual.

If you have an indirect TPMS, the process for resetting it may be a bit more complicated. You may need to remove the sensor from the wheel and then place it back on. Once the sensor is back in place, you can then re-learn the sensor IDs.

Honda tire pressure light

If your Tire Pressure Monitoring System (TPMS) light is on, it means that one or more of your tires is low on air. Don’t ignore this warning! Low tire pressure can lead to tire failure, and can be dangerous.

To reset your TPMS light, you’ll need to add air to your tires until the light goes off. You can do this at any gas station or tire shop. Once your tires are inflated to the proper pressure, the light should reset itself.

If the light doesn’t reset, or if it comes on again after you’ve inflated your tires, there may be a problem with your TPMS system. In this case, you’ll need to take your car to a mechanic or dealership to have it checked out. Don’t let a TPMS light scare you!

With a little air in your tires, you’ll be back on the road in no time.

How to Reset Low Tire Pressure Light (TPMS)

Conclusion

If your check engine light is on, or you’re experiencing issues with your Tire Pressure Monitoring System (TPMS), you may need to reset the system. Here’s how: First, check your vehicle’s owner’s manual to see if there are any specific instructions for resetting your TPMS.

If not, the following steps should work:

1. Locate the TPMS reset button, which is usually located under the dash near the steering column.

2. Press and hold the reset button for about 30 seconds.

3. Start the vehicle and drive for about 15 minutes to allow the TPMS to relearn the new tire pressure readings. If you’re still having issues with your TPMS after resetting it, you may need to have the system checked by a professional.

How To Reset Tire Pressure Light On Honda Civic 2015

Honda civic 2015 has a tire pressure light that comes on when the pressure in any tire is low. To reset this light, you will need to add air to the tires until the light goes off. The light will come back on if the pressure in any tire drops below the correct level.

- Park your Honda Civic in a level area and turn off the engine

- Locate the tire pressure sensor reset button

- This button is usually located on the dash near the speedometer

- Press and hold the tire pressure sensor reset button for about 5 seconds

- Start the engine and drive for a few miles

- The tire pressure light should now be reset

How do you reset the tire pressure sensor on a 2015 Honda Civic?

If your Honda Civic has a tire pressure light that needs resetting, follow these steps:1. Find the tire pressure sensor. On the 2015 Honda Civic, it is located on the driver’s side doorjamb.

2. Use a small object, like a paperclip, to press and hold the reset button on the tire pressure sensor.3. While continuing to hold the reset button, turn the ignition key to the “On” position.4. Keep holding the reset button for a few seconds after the ignition is turned on, then release it.

5. The tire pressure light on the dash should now be reset and should not come on again unless there is a actual problem with the tire pressure.

How do you reset the low tire pressure light on a Honda Civic?

If your Honda Civic has a tire pressure light that won’t reset, there are a few things you can do to try and fix the problem. First, check the pressure in all four tires and make sure they are all inflated to the correct level. If they are, then you can try resetting the light by disconnecting the battery for a few minutes and then reconnecting it.

If that doesn’t work, you may need to take your car to a dealer or mechanic to have the system checked out.

Does 2015 Honda Civic have TPMS?

If your Honda Civic has a tire pressure light that won’t reset, there are a few things you can do to fix the issue. First, check the tire pressure in all four tires. If any of the tires are low, fill them up to the recommended pressure.

If the light still won’t reset, you may need to have the system checked by a Honda dealer or a qualified mechanic.

How do you reset the PSI on a Honda Civic?

If your Honda Civic has a Tire Pressure Monitoring System (TPMS) light that won’t reset, there are a few things you can do to reset it. First, check the pressure in all four tires and make sure they are at the correct pressure. If they are, then drive the car for a few miles to see if the light resets itself.

If it doesn’t, then you can try the following:1. Turn the ignition key to the “ON” position without starting the engine.2. Press and hold the reset button on the instrument panel for about 5 seconds.

3. Start the engine and drive for a few miles. The TPMS light should reset itself.If the above doesn’t work, then you may need to take the car to a Honda dealer to have the system checked.

How to reset tire pressure on honda civic 2016

If your Honda Civic has a tire pressure light that needs resetting, here’s how to do it. First, find the tire pressure sensor, which is located on the inside of the wheel well. Next, use a tire pressure gauge to check the pressure in all of your tires.

If any of the tires are low, fill them up to the recommended pressure. Finally, use a reset tool to clear the tire pressure light on your dash.If you have a Honda Civic from 2015 or newer, you may have noticed that the tire pressure light comes on from time to time.

This is because your car is equipped with a tire pressure sensor that monitors the pressure in your tires. If any of the tires are low, the light will come on as a reminder to fill them up.Fortunately, resetting the tire pressure light is a pretty easy process.

First, use a tire pressure gauge to check the pressure in all of your tires.

2015 honda civic tire pressure light keeps coming on

If your Honda Civic’s tire pressure light is on, it means that one or more of your tires is low on air. To reset the light, simply add air to the tire or tires that are low. Once the pressure is back to normal, the light will reset itself.

If you’re not sure which tire is low, you can check the pressure in all four tires with a tire pressure gauge. The proper pressure for your Civic’s tires is listed in the owner’s manual.If your tire pressure light is on, don’t ignore it!

Low tire pressure can lead to premature tire wear and even a blowout. So be sure to check your tires regularly and keep them inflated to the proper pressure.

How to reset tire pressure on honda civic 2017

If your Honda Civic 2015 has a tire pressure light that needs resetting, follow these steps:1. Locate the reset button. This is usually located on the dash near the speedometer.

2. Press and hold the reset button for about 5 seconds.3. The tire pressure light should now be reset and should go off when you start driving.

How to reset tire pressure on honda civic 2019

If your 2015 Honda Civic has a tire pressure light that needs resetting, here’s what you need to do. First, make sure that all four of your tires are inflated to the correct pressure. Once they are, turn on your car and press the button on your dashboard that looks like a car with a wavy line under it.

This is the button that controls your car’s settings and features. Find the tire pressure light in the menu and press the reset button. If the light doesn’t reset, consult your car’s owner’s manual for further instructions.

2014 honda civic tpms reset

If your Honda Civic has a tire pressure light that needs resetting, there are a few things you can do. First, check the pressure in all four tires and make sure they’re at the correct levels. Once you’ve done that, you can try one of the following methods to reset the light.

Method 1:1. Turn the key to the ON position without starting the engine.2. Press and hold the trip meter reset button.

3. While still holding the button, turn the key to the OFF position.4. Release the button and turn the key back to the ON position. The light should now be reset.

Method 2:1. Turn the key to the ON position without starting the engine.2. Press and hold the trip meter reset button.

3. While still holding the button, turn the key to the OFF position.

2014 honda civic tire pressure light keeps coming on

If your tire pressure light is on in your Honda Civic 2015, it’s time to reset it. Here’s how:1. Start by checking your tire pressure.

Make sure that all four tires are inflated to the correct pressure.2. Once your tires are inflated, turn on your Honda Civic and press the “Menu” button on your dash.3. Select “Vehicle Settings” from the menu.

4. Scroll down to “Tire Pressure” and select it.5. Select “Reset” and then press “OK.”Your tire pressure light should now be reset!

Reset tire pressure honda civic 2020

If your Honda Civic’s tire pressure light is on, it means that one or more of your tires is low on air. To reset the light, simply fill up your tires to the proper air pressure.There are a few things to keep in mind when checking and filling your tires.

First, make sure that you’re using a reliable tire pressure gauge. Many gas stations have air pumps that come with a gauge, but these are often inaccurate. Second, consult your Honda Civic’s owner’s manual to find out the proper air pressure for your tires.

Overinflating your tires can be just as dangerous as underinflating them, so it’s important to get it right.Once you’ve filled up your tires, the tire pressure light should reset itself. If it doesn’t, or if it comes back on after a short while, there may be a problem with one of your tire sensors.

2013 honda civic tpms reset

If the Tire Pressure Monitoring System (TPMS) light on your 2015 Honda Civic is on, it means that one or more of your tires is low on air pressure. You can usually reset the light by filling up your tires to the proper air pressure.To find out how much air your tires need, consult your owner’s manual.

Each tire should have the proper air pressure listed on the sidewall. Once you’ve filled up your tires, the TPMS light should reset itself.If the light doesn’t reset, or if it keeps coming on even after you’ve filled up your tires, there may be a problem with your TPMS system.

In this case, you’ll need to take your car to a Honda dealer or a qualified mechanic for diagnosis and repair.

Conclusion

If your Honda Civic has a tire pressure light that won’t reset, there are a few things you can try. First, check the tire pressure in all four tires. If the pressure is low in one or more of the tires, fill them up to the recommended pressure and see if the light will reset.

If the tire pressure is fine, then the next thing to check is the TPMS sensor in each tire. If a sensor is damaged or not working properly, it can cause the tire pressure light to stay on. You’ll need to have the sensor replaced if that’s the case.

If everything looks good with the tires and sensors, then the issue may be with the fuse or the TPMS system itself. Consult your Honda Civic’s owner’s manual for more information on troubleshooting the TPMS system.

How To Remove Transmission Cooler Lines From Radiator

The transmission cooler lines are responsible for keeping the transmission fluid cool as it circulates through the radiator. Over time, these lines can become clogged with debris and need to be replaced. Fortunately, this is a relatively easy process that can be completed in a few simple steps.

- Park your vehicle on a level surface and put the transmission in park or neutral

- Locate the transmission cooler lines at the radiator

- There will be two lines, one for the inlet and one for the outlet

- Place a drain pan under the radiator to catch any transmission fluid that may drip out

- Using a wrench, loosen the transmission cooler line fittings at the radiator

- Once the fittings are loose, remove the transmission cooler lines from the radiator

- Have a rag handy to clean up any transmission fluid that may have leaked out

- Repeat the process for the other transmission cooler line

How do you remove a radiator transmission line?

If you need to remove your transmission cooler lines from your radiator, there are a few things you need to do first. First, you need to disconnect the battery so you don’t accidentally electrocute yourself. Next, you need to drain the transmission fluid.

You can do this by disconnecting the transmission cooler line from the radiator and then starting the car. Once the fluid is drained, you can remove the transmission cooler lines from the radiator. Finally, you need to refill the transmission fluid.

You can do this by adding transmission fluid to the radiator through the transmission cooler line.

How do you remove transmission oil cooler lines?

If your car has an automatic transmission, then it likely has a transmission cooler. The transmission cooler is a small radiator-like device that helps to keep the transmission fluid cool. The transmission fluid is responsible for lubricating and cooling the transmission, so it is important to keep it at the correct temperature.

If you are doing any work on your car’s transmission, you may need to remove the transmission cooler lines from the radiator. This is not a difficult task, but it is important to be careful so that you do not damage the lines.The first step is to locate the transmission cooler lines.

They will be attached to the radiator at one end, and to the transmission at the other. You will need to follow the lines from the radiator to the transmission to find where they are attached.Once you have located the lines, you will need to disconnect them from the radiator.

There will be a clamp or fitting that is holding the line in place.

How do transmission cooler lines connect to radiator?

If your transmission cooler lines are leaking, you’ll need to remove them from the radiator so that you can repair or replace them. This can be a difficult task, but with a little patience and the right tools, you can do it yourself.First, you’ll need to locate the transmission cooler lines.

They’ll be running from the transmission to the radiator, and will likely be secured with clamps. Once you’ve found the lines, you’ll need to loosen the clamps so that you can remove the lines.Next, you’ll need to disconnect the lines from the transmission.

This can be done by using a wrench to loosen the fittings. Once the lines are disconnected, you can remove them from the radiator.Finally, you’ll need to clean the fittings on the transmission and the radiator.

This can be done with a wire brush or a piece of sandpaper.

How do you disconnect a transmission line?

If your car has an automatic transmission, then it likely has a transmission cooler. The transmission cooler is responsible for keeping the transmission fluid cool, and it does this by circulating transmission fluid through a cooling system. The most common type of cooling system is a radiator, and the transmission cooler lines are what connect the transmission cooler to the radiator.

If you need to remove the transmission cooler lines from your radiator, there are a few things you need to do first. First, you need to find the transmission cooler line that goes to the radiator. This is usually easy to find, as it will be the line that is closest to the radiator.

Once you have found this line, you need to follow it to the point where it connects to the transmission cooler.At the point where the transmission cooler line connects to the transmission cooler, you will see a nut that holds the line in place. This nut needs to be removed in order to disconnect the line from the cooler.

How to remove transmission cooler lines from radiator without tool

If you need to remove your transmission cooler lines from your radiator, there are a few things you need to know. First, make sure that your vehicle is turned off and the engine is cool before beginning this project. Next, locate the transmission cooler lines on your radiator.

There are usually two lines, one for the input and one for the output.To remove the transmission cooler lines, you will need to use a line wrench. Place the line wrench on the fitting that secures the line to the radiator.

Then, turn the line wrench counter-clockwise to loosen the fitting. Once the fitting is loose, you can pull the transmission cooler line off of the radiator.Repeat this process for the other transmission cooler line.

Once both lines are removed, you can proceed with whatever repair or replacement you need to do. Be sure to use new O-rings when reinstalling the transmission cooler lines to ensure a tight seal.

Transmission lines to radiator leaking

If you need to remove the transmission cooler lines from your radiator, there are a few things you need to know. First, you need to identify which line is the input and which is the output. The input line will be the one that’s attached to the transmission, and the output line will be the one that goes to the cooler.

Once you’ve identified the two lines, you can use a wrench to loosen the line nuts at the radiator. Be sure to have a drain pan handy to catch any fluid that may spill out. Once the nuts are loose, you can remove the lines and discard them.

How to remove transmission cooler lines from radiator ford

If you need to remove your transmission cooler lines from your radiator, there are a few things you’ll need to do. First, you’ll need to disconnect the battery to avoid any electrical issues. Next, you’ll need to drain the transmission fluid.

Once the fluid is drained, you can remove the cooler lines from the radiator. Be sure to have a catch pan handy to catch any fluid that may drip out. Finally, you can reinstall the transmission cooler lines and fill the transmission with fresh fluid.

How to connect transmission lines to radiator

If you need to remove your transmission cooler lines from your radiator, there are a few things you need to know first. First, transmission cooler lines are under pressure, so you will need to relieve that pressure before you can remove the lines. Second, the lines are held in place by clips or brackets, so you will need to remove those before you can take the lines off.

To remove the transmission cooler lines from your radiator, start by finding the clips or brackets that are holding the lines in place. These are usually located near the radiator. Once you have found the clips or brackets, use a screwdriver or a pair of pliers to remove them.

Once the clips or brackets are removed, you can now pull the transmission cooler lines off of the radiator. Be careful when doing this, as the lines are still under pressure. Once the lines are off, you can now proceed to install the new transmission cooler lines.

Transmission cooler lines diagram

Removing transmission cooler lines from a radiator can be a difficult and frustrating task. However, it is possible to remove them with the right tools and a little bit of patience.The first step is to locate the transmission cooler lines.

They will be located near the bottom of the radiator, on the side that faces the engine. Once you have located the lines, you will need to identify the line that goes to the transmission and the line that goes to the radiator. The line that goes to the transmission will be the larger of the two lines.

Next, you will need to disconnect the transmission cooler line from the radiator. To do this, you will need to use a pair of pliers. First, locate the retaining clip that holds the transmission cooler line in place.

The clip is usually located near the end of the line. Once you have located the clip, use the pliers to remove it.

Conclusion

Removing transmission cooler lines from a radiator can be a difficult and time-consuming task. However, with the proper tools and a little patience, it can be done relatively easily.First, disconnect the negative battery terminal to prevent any electrical shorts.

Next, locate the transmission cooler lines at the radiator. There are typically two lines, an upper and a lower.Using a wrench or pliers, loosen the retaining nuts or clamps that secure the lines to the radiator.

Once the clamps are loose, carefully pull the lines away from the radiator. There may be some fluid leakage, so have a drain pan ready to catch any drips.With the lines removed, the final step is to clean the radiator mating surfaces.

This can be done with a rag and some brake cleaner. Once the surfaces are clean, the new transmission cooler lines can be installed.Overall, removing transmission cooler lines from a radiator is not a difficult task.

How To Replace Main Bearings Without Removing Crank

If your main bearings are starting to go, you may be able to replace them without removing the crankshaft. This can be a tricky repair, so it’s important to follow the steps carefully. First, you’ll need to remove the engine’s oil pan.

Next, you’ll need to disconnect the connecting rods from the crankshaft. Once the connecting rods are disconnected, you’ll be able to remove the main bearings. To install the new bearings, you’ll need to press them into place.

Finally, you’ll need to reassemble the engine.

Can you replace main bearings without machining?

If you’re lucky enough to have a press in your shop, replacing main bearings without removing the crankshaft is a relatively easy job. The first step is to remove the oil pan and oil pump so that you have access to the bottom of the engine. Next, remove the main cap bolts and the main cap.

Once the main cap is off, you can press the old bearings out of the block and press the new ones in. Be sure to use plenty of bearing grease on the new bearings before you install them.If you don’t have a press, you can still replace the bearings without removing the crankshaft.

The first step is to remove the oil pan and oil pump so that you have access to the bottom of the engine. Next, use a hammer and punch to drive the old bearings out of the block. Be careful not to damage the bearing surfaces.

Once the old bearings are out, you can press the new ones in.

Can you just replace main bearings?

If you’re planning on replacing your main bearings without removing the crankshaft, there are a few things you need to know. First, you’ll need to support the engine so that the crankshaft doesn’t fall out when you remove the bearings. You can do this by using a block and tackle, or a floor jack and some wood blocks.

Once the engine is supported, you’ll need to remove the oil pan and the oil pump. Then, you’ll be able to access the main bearings. To remove the old bearings, you’ll need to heat them up with a torch.

Once they’re hot, you can pry them out with a screwdriver.To install the new bearings, you’ll need to first clean the bearing surfaces with a wire brush. Then, you’ll need to apply some bearing grease to the bearings.

Once the bearings are greased, you can press them into place.

How do you remove the main bearing on a crankshaft?

If your car is making a grinding noise, it may be time to replace the main bearings. The main bearings help support the crankshaft, so if they are worn out, the crankshaft can start to wobble and cause damage to the engine. You don’t have to remove the crankshaft to replace the main bearings, but it is a good idea to have a professional do it.

Here’s how to replace main bearings without removing the crankshaft:1. Jack up the car and remove the wheels.2. Disconnect the battery.

3. Remove the oil pan.4. Remove the main bearing caps.5. Remove the old bearings and clean the crankshaft.

6. Install the new bearings and main bearing caps.7. Reinstall the oil pan.8. Reconnect the battery.

How do you install main bearings?

If your main bearings are worn out, you’ll need to replace them. But, you don’t necessarily have to remove the crankshaft to do it. Here’s how to replace main bearings without removing the crankshaft:

1. Remove the oil pan and oil pump. This will give you access to the main bearings.

2. Use a press to remove the old bearings and install the new ones.

3. Reinstall the oil pan and oil pump.

4. Fill the engine with oil and you’re good to go! This is a pretty straightforward process, but it’s important to make sure that you press the new bearings in evenly.

If you don’t, it could cause problems down the road.

Conclusion

Assuming you are referring to an engine:The main bearing caps hold the bearings in place. To remove them, you will need a socket and ratchet.

Remove the bolts holding the cap in place. The bearings will be loose now, so be careful not to drop them. You can now remove the old bearings and install the new ones.

Make sure the new bearings are seated properly and then reinstall the bearing caps.

How To Remove Carrier Bearing Without A Press

If you’re looking to remove a carrier bearing without a press, there are a few methods you can try. One is to use a chisel and hammer to tap the bearing out of the housing. You can also try using a pry bar to gently pry the bearing out.

If either of these methods doesn’t work, you can try heating up the housing with a torch and then using a pry bar to remove the bearing.

- Jack up the vehicle and support it on jack stands

- Remove the driveshaft

- unbolt the carrier bearing from the housing

- using a pry bar, carefully pry the carrier bearing out of the housing

- clean the housing and install a new carrier bearing

- re-install the driveshaft

How do you remove carrier bearings without a puller?

Assuming you don’t have access to a press, the best way to remove a carrier bearing is to use a drift punch and a hammer. Start by gently tapping the drift punch on the inner race of the bearing. As you continue to tap, the bearing will start to loosen and eventually fall out.

You may need to use a little bit of force to get the bearing out, but be careful not to damage the race. Once the bearing is out, you can clean up the race and install a new bearing.

How do you remove a carrier bearing from a drive shaft without a press?

If you’re working on a car with a rear-wheel drive layout, there’s a good chance you’ll need to remove the carrier bearing at some point. This can be a tricky process, but with the right tools and a little bit of know-how, it’s not too difficult.The first step is to remove the driveshaft.

This will give you access to the carrier bearing bolts. Once the driveshaft is out of the way, you can use a socket and ratchet to remove the bolts.Once the bolts are out, the carrier bearing can be removed by hand.

Be careful not to damage the seal.Now that the carrier bearing is out, you’ll need to install the new one. This is where a press comes in handy, but if you don’t have one, you can use a few different methods.

One method is to use a socket and ratchet to thread the new bearing onto the bolts.

How do you remove a carrier bearing from a drive shaft?

If you’re attempting to remove a carrier bearing without a press, you’re in for a bit of a challenge. carrier bearings are designed to be extremely tight-fitting, so that they can handle the immense force and weight of a transmission. This means that they can be incredibly difficult to remove without the proper tools.

That being said, it is possible to remove a carrier bearing without a press, though it will undoubtedly be a difficult and time-consuming task. The first step is to remove the transmission from the vehicle. Once the transmission is out, you’ll need to remove the differential cover.

Once the cover is off, you’ll be able to see the carrier bearing. It will be held in place by four bolts. You’ll need to use a socket wrench to remove these bolts.

Once the bolts are removed, the carrier bearing can be pried off of the differential.

How do you press a wheel bearing into a hub without a press?

If you need to remove a carrier bearing without a press, you can use a few different methods. One is to use a chisel and punch to drive the bearing out. Another is to use a hydraulic jack to push the bearing out.

Whichever method you choose, be sure to use caution and go slowly to avoid damaging the bearing or the surrounding area.

Carrier bearing removal tool

If you’re looking to remove a carrier bearing without a press, there are a few ways you can go about it. The most common way is to use a bearing puller. This is a tool that essentially uses leverage to remove the bearing.

You can also use a Hydraulic Bearing Puller, which uses hydraulic pressure to remove the bearing. Finally, you can use a Slide Hammer and Bearing Puller Set. This method uses a hammer to hit the back of the bearing, which pops it out.

Drive shaft center support bearing removal tool

If you’re looking to remove your car’s carrier bearing without a press, there are a few different ways you can go about it. One option is to use a bearing separator, which is a tool that sits over the bearing and pulls it off. Another option is to use a gear puller, which is a tool that attaches to the teeth of the gear and pulls it off.

And lastly, you can use a hydraulic jack to push the bearing out from the inside.Here’s a step-by-step guide on how to remove your car’s carrier bearing without a press:1. Start by removing the bolts that hold the bearing in place.

You’ll likely need a socket wrench to do this.2. Once the bolts are removed, you can use a bearing separator to pull the bearing off. Just place the separator over the bearing and turn the handle to pull it off.

How to remove carrier bearing off drive shaft

If you’re planning on removing a carrier bearing without a press, there are a few things you’ll need to keep in mind. First, you’ll need to support the carrier bearing with a block of wood or something similar. This will prevent the carrier bearing from falling out while you’re removing it.

Next, you’ll need to use a hammer to gently tap on the carrier bearing. Be careful not to hit it too hard, as this could damage the bearing. Once the carrier bearing is loose, you should be able to remove it by hand.

Carrier bearing removal tool autozone

If you’re planning on removing your carrier bearing without a press, there are a few things you’ll need to keep in mind. First, you’ll need to support the weight of the differential with a jack or similar device. Next, you’ll need to remove the bolts that hold the carrier bearing in place.

Once the bolts are removed, the carrier bearing can be carefully removed by hand.Keep in mind that the carrier bearing is under a lot of tension, so be careful not to damage it when removing it. Also, be sure to clean the area around the carrier bearing before reinstalling it.

Once the new carrier bearing is in place, you can then bolt it down and lower the differential.

Diy carrier bearing puller

If you’re looking to remove a carrier bearing without a press, there are a few different methods you can try. One is to use a screwdriver and a hammer to gently tap the bearing out of its housing. Another is to use a pry bar to lever the bearing out.

Whichever method you choose, be careful not to damage the housing in the process. Once the bearing is out, you can inspect it for damage and replace it if necessary.

Heavy duty carrier bearing puller

If you’re faced with removing a carrier bearing without a press, never fear! There are a few ways to do it without all the fancy equipment.One way is to use a large screwdriver or pry bar.

Place the tip of the screwdriver or pry bar under the lip of the bearing, and then hit the other end with a hammer. This will slowly loosen the bearing. You may need to do this a few times to get the bearing completely loose.

Another way is to use a socket and a ratchet. Place the socket over the bearing, and then ratchet it until the bearing pops out.Once the bearing is loose, you can remove it by hand.

Be careful not to damage the shaft or the housing while you’re doing this.With a little elbow grease, you can remove a carrier bearing without a press!

Conclusion

If you’re looking to remove your carrier bearing without a press, there are a few different ways you can do it. One way is to use a slide hammer, which is essentially a large metal rod with a handle on one end and a hook on the other. You attach the hook to the bearing, and then use the handle to apply pressure and force the bearing out.

Another way you can remove the carrier bearing without a press is by using a pry bar. Place the pry bar under the bearing and then apply pressure to pry it out. You may need to use a few different pry bars to get the job done, depending on the size and strength of the bearing.

Once you have the carrier bearing removed, you can then proceed to remove the rest of the bearings in the same manner. Just be sure to work slowly and carefully to avoid damaging any of the other parts in the process.

How To Check Tire Pressure Honda Civic 2018

Assuming you would like a step-by-step guide on how to check the tire pressure for a Honda Civic in 2018:Start by parking your Honda Civic on level ground and turning off the engine. Next, locate the tire pressure gauge on the driver’s side door.

Unscrew the cap to the tire pressure gauge and press the gauge firmly onto the valve stem of the tire. The gauge will give you a reading of the current tire pressure. Compare this number to the recommended tire pressure for your Honda Civic, which can be found in the owner’s manual or on the door placard.

If the number on the gauge is lower than the recommended tire pressure, use a tire air pump to add air to the tire until it reaches the recommended pressure. If the number on the gauge is higher than the recommended tire pressure, use the tire air pump to release air from the tire until it reaches the recommended pressure.

- Open the driver’s side door and locate the tire pressure information label on the door frame

- Locate the recommended tire pressure for your Honda Civic on the label

- Use a tire pressure gauge to check the pressure of each tire

- Add air to each tire as needed to reach the recommended pressure

How do I check my tire pressure on Honda Civic?

It is important to check your tire pressure regularly to maintain optimal performance and safety while driving. The recommended tire pressure for a 2018 Honda Civic is 32 psi for the front tires and 30 psi for the rear tires.To check the pressure in your tires, use a digital tire pressure gauge.

Insert the gauge into the tire valve and wait for the reading to stabilize. Compare the reading to the recommended pressure for your tires. If the pressure is too low, add air to the tires until they reach the proper pressure.

If the pressure is too high, release air from the tires until they reach the proper pressure.It is also important to check the condition of your tires regularly. Look for signs of wear and tear, such as cracks, bald spots, or bulges.

If you notice any damage, replace the tire immediately.Driving on properly inflated and maintained tires will help improve your fuel economy and extend the life of your tires.

Does a 2018 Honda Civic tell you tire pressure?

It’s important to check your tire pressure regularly, and it’s especially important to do so before long trips. Here’s how to check the tire pressure on your 2018 Honda Civic:1. Park your Civic on a level surface and turn off the engine.

2. Locate the tire pressure monitoring system (TPMS) reset button, which is located on the driver’s side of the instrument panel.3. Press and hold the TPMS reset button for about 5 seconds.4. The TPMS system will chime and the low tire pressure warning light on the dash will turn off.

5. Use a tire pressure gauge to check the pressure of all four tires. The ideal pressure for the 2018 Civic is 32 psi.6. If any of the tires are low on pressure, use a air compressor to add air until the pressure is at the proper level.

7.

How do you check tire pressure on a 2018?

If you own a Honda Civic from 2018 or newer, you may be wondering how to check your tire pressure. Here’s a quick guide on how to do just that:First, locate the tire pressure monitoring system (TPMS) reset button on your dash.

It should be near the bottom of the center stack, to the left of the steering wheel.Next, use a tire pressure gauge to check the pressure in each of your tires. The ideal pressure for a Honda Civic is 32 psi (pounds per square inch).

If any of your tires are low on pressure, use a portable air compressor to add air until the pressure is at the correct level.Once you’ve checked and corrected the pressure in all four tires, press and hold the TPMS reset button for about five seconds. This will reset the system and allow it to properly monitor your tire pressure going forward.

That’s all there is to it!

Where is the TPMS button on a 2018 Honda Civic?

It is always important to keep your tires properly inflated. This helps with fuel economy and extends the life of your tires. You should check your tire pressure at least once a month.

You can do this easily at home with a tire pressure gauge.To check your tire pressure on a Honda Civic 2018, first locate the tire pressure monitoring system (TPMS) reset button. This is usually located on the driver’s side, near the instrument panel.

Once you have found the reset button, press and hold it for about 5 seconds.Next, use your tire pressure gauge to check the pressure in all 4 tires. The recommended tire pressure for a Honda Civic 2018 is 32 psi.

If any of your tires are low, use a portable air compressor to add air until the pressure is back to 32 psi.Finally, press the TPMS reset button again to turn off the tire pressure warning light.

How to check tire pressure honda civic 2016

If you own a Honda Civic 2018, you may be wondering how to check the tire pressure. Luckily, it’s a pretty simple process. All you need is a tire pressure gauge.

First, find the tire pressure sticker on your driver’s door. This will tell you the recommended tire pressure for your car. Then, use your tire pressure gauge to check the pressure in each tire.

If the pressure in any tire is below the recommended amount, use a air compressor to add air until it reaches the correct level. Then, check the pressure again to make sure it’s at the right level.That’s all there is to it!

Checking your tire pressure is a quick and easy way to keep your car running smoothly.

How to check tire pressure on honda civic 2019

If you own a Honda Civic 2018 or any other vehicle with tires, it’s important to know how to check the tire pressure. This is a simple process that only takes a few minutes and can save you a lot of money in the long run. Here’s how to do it:

1. Locate the tire pressure gauge. This is usually located near the air fill valve on the side of the tire.2. Remove the valve cap from the tire.

3. Place the tire pressure gauge on the valve and press down firmly to get a reading.4. Compare the reading to the recommended tire pressure for your vehicle. This can be found in the owner’s manual or on a sticker inside the driver’s door.

5. If the reading is lower than the recommended pressure, use an air compressor or tire inflator to add air to the tire until it reaches the proper pressure.

How to check tire pressure honda civic 2020

If you own a Honda Civic 2018, you may be wondering how to check the tire pressure. It’s actually quite simple! Here’s what you need to do:

1. Locate the tire pressure monitoring system (TPMS) reset button, which is located on the driver’s side door panel.2. Press and hold the reset button for about 5 seconds.3. The TPMS system will then enter learning mode, and the Tire Pressure light on the dash will illuminate.

4. Now, simply drive around for a bit until the light goes out. This means that the system has learned the new tire pressure and is now functioning properly.That’s all there is to it!

Checking the tire pressure on your Honda Civic 2018 is quick and easy. Now you can hit the road with peace of mind, knowing that your tires are properly inflated.

How to check tire pressure honda civic 2017

If you own a Honda Civic from 2018 or newer, checking your tire pressure is easy! All you need is a digital tire pressure gauge.To check your tire pressure: