Author Archives: David V. Williamson

If you're looking for a way to upgrade your road bike without spending a lot of money, switching to tubeless tires may be the answer. Tubeless tires are gaining popularity because they offer several advantages over traditional clincher tires.

The first advantage is that tubeless tires are easier to install and remove. There's no need for a tire lever, and you can usually get them on and off without any tools. They are also ideal for cyclists who prefer to travel light, making them an excellent choice.

The second advantage is that tubeless tires are more puncture resistant than traditional clincher tires. This is because there's no tube inside the tire, so if you get a puncture, the air will escape slowly rather than all at once.

Why use tubeless tires on a road bike?

Reduced chance of getting a flat

One of the benefits of using tubeless tires on your road bike is that you have a reduced chance of getting a flat. The sealant filler in the tire means that you get a level of puncture protection beyond what you would get with a simple strip.

When the sealant dries, it plugs the hole, fixing the puncture and preventing air from leaking out. Tubeless tires also offer a much faster ride than traditional tube-type tires.

If you have a puncture that is more than 5mm in size, tubeless tires will not be able to help fix the problem quickly enough to keep you safe on your bike.

In this case, you can use the plug system as a last resort after the sealant fails. The plug system will help prevent further puncture damage, but it won't protect against something like a broken spoke or rim.

Lighter weight

Another advantage of using tubeless tires is that they weigh less than conventional tubes, making them easier to mount and dismount. They also make it easier to maintain your bike's speed when climbing hills.

Increased speed

Since no friction exists between the tire and the wheel casing, tubeless tires are usually faster than tubed tires. This allows the bike to move more easily and with less resistance.

What are the benefits of using tubeless tires on a road bike?

Reduced chance of getting a puncture

One of the benefits of using tubeless tires on a road bike is that you have a reduced chance of getting a puncture. There are no holes in the tire, so it can't puncture. Also, tubeless tires are often made of Kevlar, making them more puncture-resistant.

More comfortable ride

Tubeless tires are designed to provide an airtight seal with the rim and carry more speed on loose surfaces. Tubeless tires can even reduce rolling resistance on rough surfaces. A supple tire retains its shape well when inflated, perfect for road bikes as they rely on a smooth ride over bumps or cobblestones.

Tubeless tires are thinner and deform more easily, leading to a more comfortable ride. The casing is reduced because there's no need for an inner tube - meaning that you'll experience less fatigue on your rides.

How to choose the best tubeless tire for your road bike?

When selecting tubeless tires for your road bike, you should consider a few factors. The first thing is what type of riding you will be doing. You might like the Bontrager R3 or Continental Grand Prix 5000 TL if you mostly ride on paved roads.

If you're looking for more performance and are willing to sacrifice a bit of durability, then the Hutchinson Sector 28 could be a good choice.

A tubeless tire that offers great grip, traction, and durability while still being lightweight is the Maxxis Highroad HYPR K2. However, keep in mind that these tires can be more expensive than some of the other options on the market.

Another thing to consider when choosing a tubeless road tire is your bike's brake type. Disc brakes can be easily assembled at home following online video tutorials reducing the cost of bike shop service. And finally, make sure you choose the right size tire for your frame and riding style.

How to install a tubeless tire on your road bike?

Installing a tubeless tire on your road bike can be tricky, but it's doable with the right tools and knowledge.

First, you'll need to ensure that your bike is compatible with tubeless tires. Most modern bikes are designed for use with tubeless tires, but some older models may not be compatible. Before purchasing new equipment, check with the manufacturer if you're unsure whether tubeless tires are compatible with your motorcycle.

To proceed, you will need to ensure that you are equipped with the proper tools, a pump, and tubes (if you are still using them). You can purchase these tools separately or as part of a kit designed to install tubeless tires.

Once you have the proper tools, it's time to get started! The first step is to seal the rim of your wheel. Several methods are available, but the best way is to use a sealant product like Stan's NoTubes Tire Sealant. Once the rim is sealed, add the sealant to your tire and install it on the wheel.

Now comes the tricky part: inflating the tire. Most tires will inflate much more easily if you use a bike pump with a built-in gauge, but some may require an air compressor instead.

If you're using an air compressor, set the pressure to no more than 5 bars (70 psi). Once the tire is inflated, check for leaks and make necessary adjustments.

That's it! You've now successfully installed a tubeless tire on your road bike. Congratulations!

Tips for maintaining your tubeless tires on your road bike

The sealant will help you avoid flats.

If you're using tubeless tires on your road bike, adding sealant is good, and this will help you avoid flats. There are several types of sealant available, and each one has its strengths and weaknesses.

Some sealants dry out quickly at high pressures, while others last longer. If your sealant runs out or isn't working, you can try using a tubeless plug to close the hole.

However, if other options aren't working, your best bet is to carry a pump and spare tube with you on your rides. Keep in mind that some holes are too large for the sealant to fix.

To find the best sealant for you, take our test. We've compared six different types of sealant to see which one works best.

When you use lower pressures, you won't experience pinch flats.

Most cyclists are familiar with the term "pinch flat." This is when you hit a bump in the road, and suddenly your tire goes completely soft. You might have even experienced this yourself.

It has been traditional to carry a spare tube with you as a solution to this problem. However, there's another option - running tubeless tires at lower pressures.

Removing the tube from the equation eliminates one of the main causes of pinch flats. Therefore, you can run the right pressure on your wheels based on your weight, and you probably need a lot less pressure than you think.

For example, if you weigh 150 pounds, running 25 psi in your tires instead of 100 psi can make a big difference.

The benefits of running tubeless tires at lower pressure reduce the risk of pinch flats while also providing a more comfortable ride. But that's not all - running low pressure on your bike will also make flat resistance better.

When combined with an appropriate sealant, this makes it much less likely that you'll get a flat tire in the first place.

You can keep these tips in mind when you're riding and cycling with a road bike by thinking about a full balloon vs. one that is not as full. When the balloon is full, it's difficult to bend. However, when the balloon isn't as full, it's much easier to deform it.

This is similar to what happens when you're riding a bike with low-pressure tires. They're more flexible and better able to absorb bumps in the road, making your ride much more comfortable.

Should I convert my road bike to tubeless?

Tubeless tires are a great concept for your road bike, and they offer many advantages. For one, you don't have to inflate them before every ride- this can save you some time and hassle.

Additionally, since there is no tube inside the tire, it's less likely that you'll get a flat. Tubeless tires also provide a smoother ride than traditional tubes, and they're often lighter weight.

If you're thinking about making the switch to tubeless tires, there are a few things you need to know first. Before making any changes to your bike, talk to your local bike shop about whether your model is compatible with tubeless technology.

Additionally, you may need extra equipment and adjustments to convert your bike- it's best to check with your local shop.

Once you've made the switch to tubeless tires, be sure to take good care of them! Check the air pressure and make sure they're inflated properly- too little or too much pressure can pose problems.

Can you go tubeless on a road bike?

There are pros and cons to going tubeless on a road bike. The lower pressure issue means a slower ride. Small bumps cause small losses in momentum and resistance to the wheel's ability to roll.

This is where tubeless tires come into their own faster due to less rolling friction. As tubular tires have more suppleness and can more easily conform to imperfection, they will be faster for a given power output, which means cycling faster will be easier.

Can you put tubeless tires on a road bike?

A tubeless tire can be mounted and removed without a compressor, and it allows riders to switch between different tires without bringing bulky equipment. In addition, this will enable you to fix or change your tire more easily if needed while out on a ride.

Some tubeless tires may be worth testing out, depending on your needs. The Continental Grand Prix S TR and Schwalbe Pro One TLE have similar tire loss rolling resistances. Additionally, you should consider other factors, including weight and puncture resistance.

Are tubeless tires better for road bikes?

There is a lot of debate surrounding tubeless tires on road bikes. Some people swear by them, while others find that they don't offer any real benefits over traditional inner tubes. The advantages and disadvantages of riding tubeless are discussed in this article.

Lower pressure means a faster ride - this is one of the main reasons people choose to go with tubeless tires. Without an inner tube, the bike will not be as quick when taking on imperfections of the road, and it will incur small losses in momentum.

As tubeless tires are more flexible, you will experience less rolling resistance and be able to travel at higher speeds.

Tubeless tires also have the advantage of being less susceptible to punctures. If you do get a flat tire, all you have to do is replace the outer casing rather than an entire inner tube. Due to the rubber compound's increased suppleness, people find tubeless setups more comfortable.

A detailed explanation of what tubeless road tires are all about.

Tubeless tires are great because they're easy to fit and remove. But there are some downsides too. You'll need to know how to fit them before properly taking them off the tubes. And if you do decide to take them off, you'll need to make sure to put them back on correctly.

Can I use tubeless road tires without carrying a tube?

A tire without tubes is better than having none at all. When you need a tube, you can buy one at any time. With tubeless tires, you don't have to worry about punctures.

How much pressure should I run in tubeless road tires?

Tubeless tires are better than tubes because they're easier to inflate and maintain. Lowering the pressure makes them last longer, and lower pressure also gives you more flexibility and less chance of flats.

How do I fit tubeless road tires?

We've got a guide for you. Check out how to install tubeless tires for step-by-step instructions.

Road Bike Tubeless Tyre maintenance and puncture repair guide

Road bikes are great for riding around town or even commuting. However, if you want to go fast, you need to get yourself a racing bike. Racing bikes use different parts than regular bikes.

For example, racing bikes usually have disc brakes instead of traditional pads. Also, racing bikes have thinner tires, making them faster because there is less friction when turning.

Road bikes use tubeless tires instead of tubes. Tubeless tires are more durable than tubes because they do not need an inner tube. Rubber seals prevent punctures by filling the space around the tire.

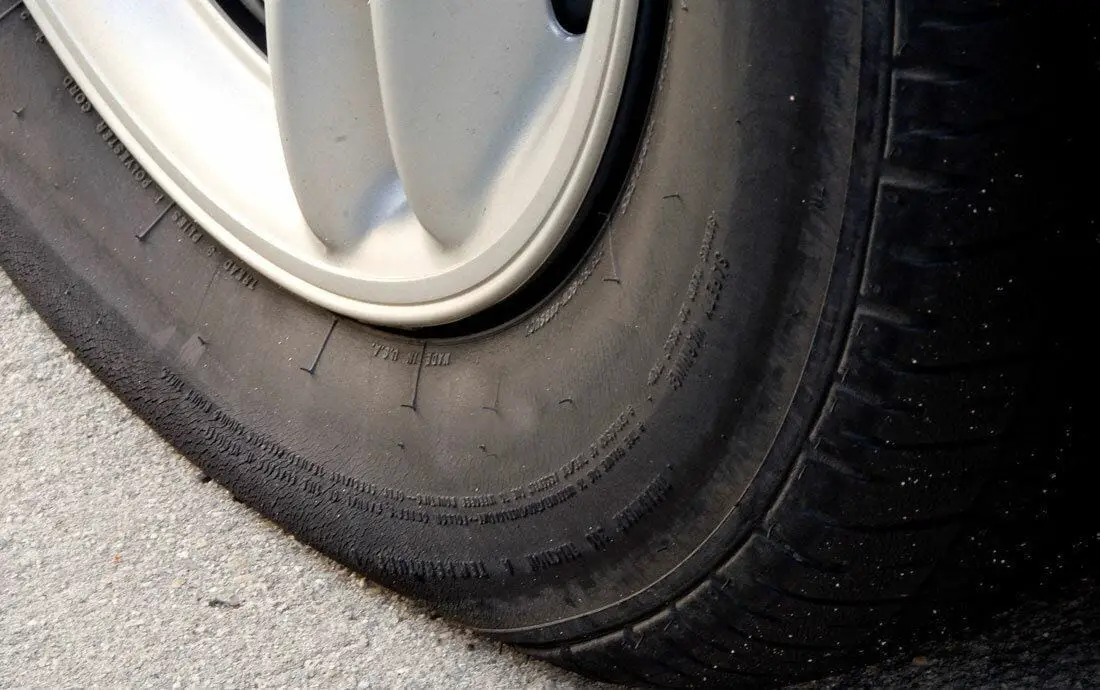

Tubeless tires are not completely puncture-proof, sealants can't fix large tire cuts, and high air pressure forces the sealant through rather than sealing larger holes. A tire cut that won't seal has two quick and simple techniques that can be used to fix it.

Tubeless Repair Kits Tubeless plugs are a quick and easy way to repair a puncture. You can continue using the tire for many miles.

Inner tubes are used to fix a punctured tire, and you must remove the valve first before fitting a new inner tube. You should always have a spare tube on you when you ride. Don't forget to check the rim for sharp objects.

A tubeless tire should be repaired with a tube or tire boot. Tubeless tires need to be patched with a tube or tire boots. Duct tape is used to reinforce the repair and ensure the tire stays inflated, and super glue is used to seal the tread back into place.

Tubeless tire maintenance: The main maintenance you'll need to do on your tubeless tires includes checking that the sealant stays topped up. It's also important to ensure that a little bit of latex is present inside the tire; otherwise, it'll need more sealant.

More often than not, your tire loses air pressure because you've run out of sealant. Add some new sealant to the inside of the tube, and the problem will be solved.

Another issue can be damaged rim tapes. If the tire has lost pressure or you have changed tires, the rim tape can become damaged or, in some cases, peel up.

Renewing the rim tapes ensures a good rim seal and seals any unnoticed leak. Our tubeless tire fitting video explains thoroughly how to replace the rim tapes.

Conclusion

You can, therefore, find the best road bike tubeless tires by following the tips provided in this article.

Compared to clincher tires, tubeless tires offer many benefits for those who ride their bikes on paved roads. You may want to contemplate switching to tubeless tires to improve your cycling experience.