How the Air Compressor Works? | Tips & Advice

An air compressor is a machine that compresses air. It typically contains one or more cylinders that draw in air and compress it. The compressed air is then sent to a storage tank where it can be used later.

Air compressors are used in many industries, including automotive manufacturing, construction, and mining.

If you own or operate a business that uses air compressors, it’s important to understand how they work. Here’s a quick overview of the basics: an air compressor is a machine that takes in air and compresses it using a piston, crankshaft, or other types of mechanism. The compressed air is then stored in a tank until it’s needed.

When the compressed air is released from the tank, it powers tools like impact wrenches and paint guns. The amount of pressure that the air compressor can generate depends on its size and design. Most home-use models can generate about 90 PSI, while industrial models can go up to 200 PSI or more.

The basic principle behind an air compressor is simple, but there’s a lot of engineering that goes into making one that’s safe and efficient. If you’re curious about how your air compressor works (or if you need to troubleshoot a problem), there are plenty of resources available online and in your owner’s manual. With a little bit of knowledge, you can keep your air compressor running smoothly for years to come.

How Does an Air Compressor Work? (Compressor Types) – Tutorial Pneumatics

Air Compressor Working Principle Pdf

An air compressor is a machine that converts power into potential energy stored in pressurized air. By one of several methods, an air compressor forces more and more air into a storage tank, increasing the pressure. When the desired pressure is reached, the air compressor shuts off, and the tank pressure maintains the system pressure.

The compressed air can be released by depressing a valve to use it for operating pneumatic tools and other equipment how Air Compressors Work The key component of an air compressor is the pump.

The pump draws in atmospheric air and compresses it, raising its temperature in the process. Most home workshop compressors are single-stage units. They draw in atmospheric air at about 14 psi (pounds per square inch) and deliver it at 115 psi to 125 psi after compressing it to less than half its original volume.

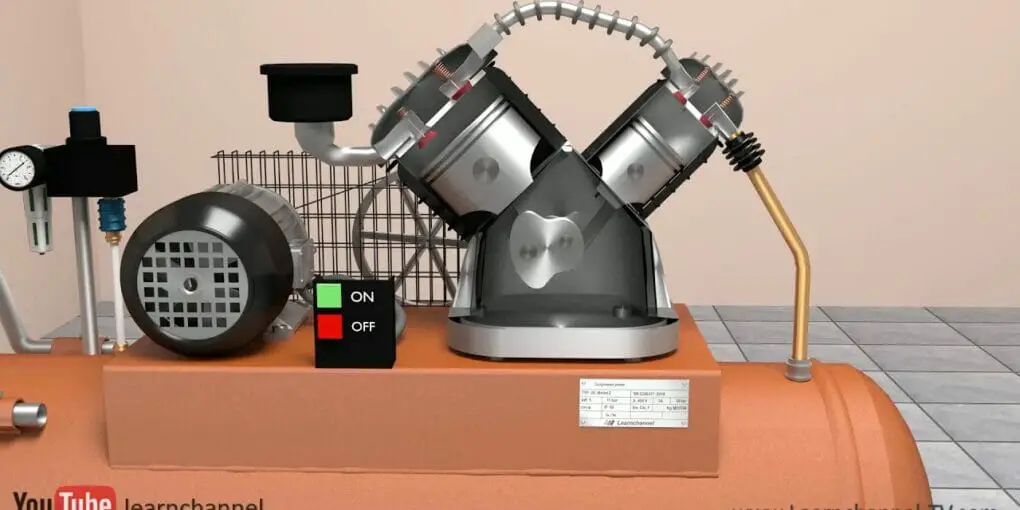

As shown in Figure 1, single-stage compressors typically have one cylinder with a piston that moves up and down inside it. Air enters through an intake valve at low pressure (LP). As the piston moves downward, it increases the volume of the LP chamber, drawing in atmospheric air; as it moves upward again toward the top dead center (TDC), this same piston compresses the LP chamber, delivering high-pressure (HP) compressed air out through an exhaust valve to fill an attached storage tank until shut off by either a pressure switch or manual intervention.

A typical single-stage reciprocating piston compressor has an LP cylinder on one side of a crankshaft and an HP cylinder on the other side. Each cylinder has its own intake and exhaust valves.

Working Principle of Air Compressor on Ship

An air compressor is a mechanical device that converts power into potential energy stored in pressurized air. By one of several methods, an air compressor forces more and more air into a storage tank, increasing the pressure. When the desired pressure is reached, the air compressor shuts off.

The compressed air, now at a much higher pressure than atmospheric pressure, is held in the tank until needed.

Types of Air Compressors

If you’re in the market for an air compressor, it’s important to know the different types that are available and which one will best suit your needs. Here is a rundown of the most common types of air compressors:

1. Piston Compressors: This type of air compressor uses piston-driven cylinders to compress air. They’re typically used for light-duty applications like powering small tools.

2. Rotary Screw Compressors: These compressors use two rotating screws to draw in and compress air. They’re more powerful than piston compressors and can be used for heavy-duty applications such as operating pneumatic tools or inflating tires.

3. Centrifugal Compressors: These compressors use a rapidly spinning impeller to draw in and compress air. They’re often used in industrial settings where large volumes of compressed air are needed, such as in factories or power plants.

How Does a Refrigerator Compressor Work?

A refrigerator compressor is a vital component of your fridge, and it’s important to understand how it works in order to keep your food fresh. The compressor is responsible for circulating coolant through the fridge coils. This process helps to remove heat from the interior of the fridge so that your food stays cold.

The compressor is powered by an electric motor, and it works by compressing refrigerant gas. This creates a high-pressure environment inside the compressor, which forces the refrigerant through the coils. As the refrigerant passes through the coils, heat is transferred from the interior of the fridge to the outside air.

The cooled refrigerant then moves back into the compressor, where the cycle begins again. This continuous cycle ensures that your food stays cold and fresh.

Credit: www.campbellhausfeld.com

What is the Function of the Compressor, And Basically, How Does It Work?

The function of a compressor is to increase the pressure of a gas by reducing its volume. Compressors are used in a wide variety of applications, including air conditioning, refrigeration, and car engines. How does a compressor work?

At its most basic, a compressor is a pump that increases the pressure of a gas by compressing it. When the gas is compressed, its molecules are forced closer together, resulting in an increase in pressure. The amount of compression that a compressor can achieve is limited by the laws of thermodynamics.

Compressors are classified according to their principle of operation. The most common type of compressor is the piston type, which uses reciprocating motion to compress the gas. Other types include screw compressors, vane compressors, and scroll compressors.

How Does a Compressor Generate Air?

A compressor is a mechanical device that increases the pressure of a gas by reducing its volume. An air compressor is a type of gas compressor that compresses air to supply high-pressure clean air to various types of equipment, including scuba tanks and paintball guns. Air compressors are either piston-type or rotary screw-type.

Piston compressors work by drawing in air through an intake valve and then trapping it in a chamber between the piston and the cylinder head. As the piston moves up, it reduces the volume of the chamber, which increases the pressure of the trapped air. The compressed air is then forced out through an exhaust valve as the piston moves back down.

Rotary screw compressors work using two intermeshing helical screws (rotors) housed inside a casing. As one rotor turns clockwise, it draws in air from one end of the casing and forces it towards the other end, where it meets the second rotor turning counterclockwise. This second rotor further reduces the volume of air before it exits via an outlet at high pressure.

What are the 2 Principles of Air Compressors?

Air compressors are powered by either electricity or gas, and they work by pressurizing air and storing it in a tank. There are two principles that all air compressors follow: positive displacement and negative displacement. Positive displacement compressors work by trapping a volume of air in a chamber and then reducing the volume of that chamber.

This increases the pressure of the air, which is then stored in a tank. Common types of positive displacement compressors include piston, vane, lobe, scroll, and screw compressors. Negative displacement compressors work by drawing air into a chamber and then forcing it out of that chamber.

This also increases the pressure of the air, which is then stored in a tank. Common types of negative displacement compressors include rotary vane, reciprocating, centrifugal, and Roots blowers.

What is the Process of the Compressor?

A compressor is a mechanical device that increases the pressure of a gas by reducing its volume.

Compressors are similar to pumps: Both increase the pressure on a fluid, and both can transport the fluid through a pipe. As gases are compressible, the compressor also reduces the volume of a gas.

Liquids are relatively incompressible; while some can be compressed, the main purpose of a pump is to pressurize and transport liquids. Compressors come in many types, including reciprocating, screw, scroll, centrifugal, axial-flow, and rotary vane compressors. Each type uses different methods to compress gases.

Reciprocating compressors use piston-driven cylinders, while screw compressors employ meshing helical screws. Scroll compressors utilize two interleaved spiral scrolls, while centrifugal models feature an impeller that spins at high speed to draw air into an annular chamber, where it is then discharged under increased pressure. Axial-flow compressors contain rotating blades that draw air into parallel passages where it is collected and discharged under increased pressure.

Rotary vane compressors feature sliding vanes that seal against the walls of a spinning chamber to trap pockets of air that are then compressed as they exit through an outlet port.

Read Another Post: How Snow Tires Work? Snow Tire Safety

Conclusion

How the Air Compressor Works An air compressor is a machine that increases the pressure of air by compressing it. This machine is powered by either an electric motor or a gasoline engine.

The compressor pumps the air into a storage tank, which increases the pressure inside the tank. When you use an air-powered tool, like a nail gun, the compressed air flows from the tank through a hose to the tool. The air pressure in the tank forces the nails out of the gun.