Author Archives: David V. Williamson

- Home

- Author's Archive:

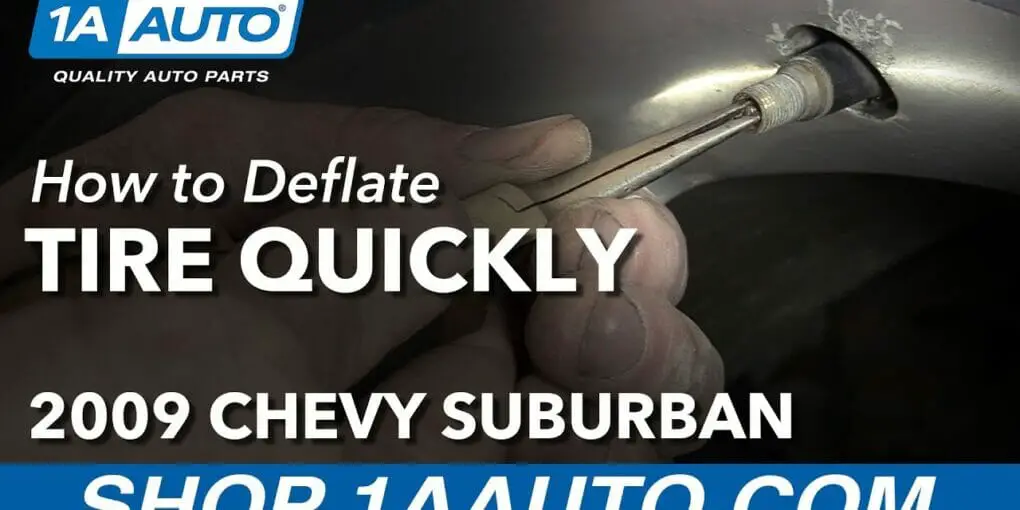

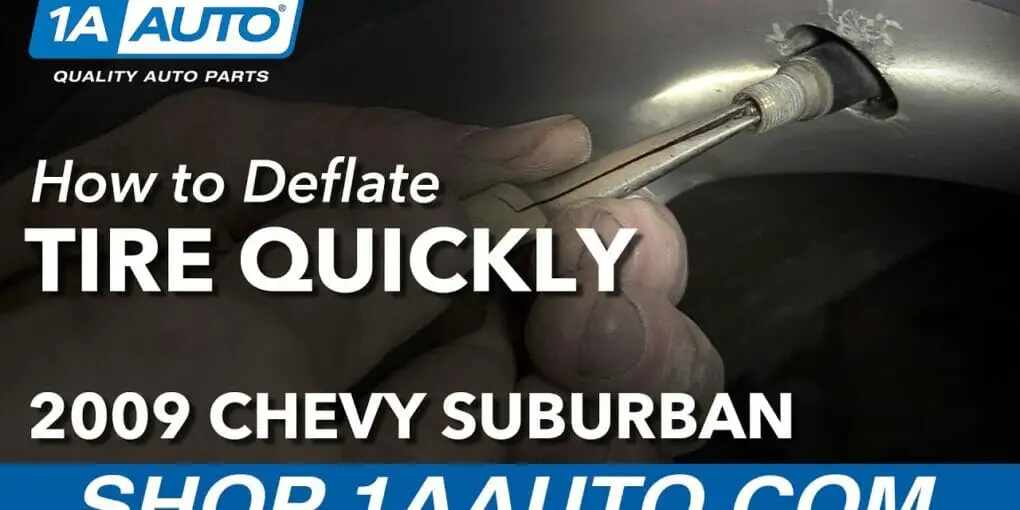

How to Decrease Air Pressure in Tires

If your car’s tires are inflated to a higher pressure than recommended by the manufacturer, you can decrease the air pressure in them by using a tire gauge to let out some of the air. You’ll want to check your owner’s manual or look for a placard on the doorjamb or inside fuel door to find the correct tire pressure for your car. Once you know that, use a digital or analog tire gauge to check the pressure in each tire.

If it’s above the recommended amount, press down on the valve stem with the gauge to release some of the air until it reaches the desired level.

Let Air Out of a Tire

- Locate the valve stem on your tire

- It is the metal part sticking out of the tire that has a cap on it

- Use a tire gauge to check the pressure in your tires

- You can find these at most gas stations

- If the pressure in your tires is too high, use a tire air pump to reduce the pressure

- Most pumps have a gauge built into them so you can pump air until the desired pressure is reached

- Remove the pump from the valve stem and replace the cap on the stem to keep dirt and debris out

How to Take Air Out of Tire Without Tool

It is very easy to take air out of a tire without using any tools. All you need is a sharp object like a nail or a screwdriver. Just insert the sharp object into the tire and press down on it.

The air will start to come out of the tire. Keep pressing until the desired amount of air has been released.

How to Reduce Tyre Pressure at Petrol Station

If your car has a tyre pressure monitoring system (TPMS), you’ll need to reset it when you reduce the tyre pressure. Here’s how to do it:1. Drive to a petrol station and park your car.

2. Switch off the engine and engage the handbrake.3. Find the valve on each tyre that you want to deflate and unscrew the cap.4. Press down on the valve with your thumb or a suitable object, such as a tire iron, until air starts escaping from the tyre.

5. Continue pressing down on the valve until the desired amount of air has escaped from the tyre. For most cars, this will be between 2-4 psi (pounds per square inch).6. Once you’ve let out enough air, screw the cap back onto the valve and repeat steps 3-5 for each remaining tyre that you want to deflate.

How to Get Air Out of Tires Quickly

If you’ve ever had a flat tire, you know how frustrating it can be. You’re either stuck on the side of the road or have to spend a lot of time and effort getting the air out of your tires. Luckily, there are a few ways that you can get air out of your tires quickly so that you can get back on the road.

One way to get air out of your tires quickly is to use a tire deflator. These devices attach to your tire valve and allow you to release all of the air from your tire at once. This is a quick and easy way to get all the air out of your tires, and it’s especially useful if you have multiple flat tires.

Another way to get air out of your tires quickly is by using a compressor. A compressor will pump all of the air out of your tires in just a few minutes. This is a great option if you only have one or two flat tires, as it will save you time and effort.

Finally, if you don’t have access to a deflator or compressor, you can always let the air out of your tires manually. This process will take longer than using a device, but it’s still relatively quick and easy. Simply remove the valve cap from your tire and use something sharp (like a nail) to puncture hole in the center of the valve stem.

Doing this will allow all of the air to escape from your tire slowly over time. Just be sure not monitor your progress so that you don’t accidentally let too much air out!

How to Lower Tire Pressure Without a Gauge

If you’re wondering how to lower tire pressure without a gauge, there are a few methods you can try. One is to use the pressure release valve on the tire itself. Another is to remove the valve stem cap and depress the valve with your finger.

If you have an air compressor, you can also use that to release some of the pressure in the tire. Just be sure not to overdo it, as too much pressure can cause problems with your tires.

How to Let Air Out of Tire Without Screwdriver

It is very common for tires to become inflated over time. When this happens, you will need to let some air out of the tire in order to bring it back down to its proper pressure. You can do this without a screwdriver by using a tire pressure gauge.

First, locate the valve stem on the tire. This is the small metal cap that sticks out from the side of the tire. Once you have found it, unscrew the cap and keep it handy.

Next, take your tire pressure gauge and place it over the valve stem. Press down firmly until you hear a hissing sound. This means that air is escaping from the tire.

Keep pressing down until the desired amount of air has been released. Finally, screw the cap back onto the valve stem to prevent any further air loss.

Credit: www.youtube.com

What Happens If My Tire Pressure is Too High?

If your tire pressure is too high, it can cause a blowout. This is when the tire suddenly loses all its air, causing the rim of the wheel to come into contact with the ground. This can be extremely dangerous as it can lead to loss of control of the vehicle.

How Do You Deflate a Tire Fast?

If you have a flat tire, the best way to deflate it quickly is to use a tire inflator. If you don’t have one, you can deflate your tire by using a screwdriver or a pen.To deflate your tire with an inflator, first remove the cap from the valve stem.

Next, insert the nozzle of the inflator into the valve stem and press down on the trigger. The air will start to flow out of the tire and it will deflate quickly.If you are using a screwdriver or a pen to deflate your tire, first find the small hole in the center of the wheel.

This is where the air goes in and out of the tire. Once you find this hole, insert the tip of your chosen tool into it and twist until you hear hissing noise. This means that air is escaping from the tire and it will be fully deflated in no time!

Is 40 Psi Too High for Tires?

No, 40 psi is not too high for tires. In fact, most tires require at least 32 psi to function properly. While 40 psi may be higher than necessary, it is not too high and will not cause any damage to your tires.

Conclusion

In order to decrease the air pressure in your tires, you will need to use a tire gauge. You can purchase a tire gauge at most auto parts stores. Once you have a tire gauge, insert the metal end into the valve stem on your tire.

Turn the knob on the tire gauge until it is snug against the valve stem. Then, press down on the handle of the tire gauge in order to release air from your tires. Continue pressing down on the handle of the tire gauge until you have reached your desired air pressure.

How to Crown Urethane Bandsaw Tires

Urethane bandsaw tires are an important part of any woodworking shop. They provide a smoother cut and a more consistent finish than traditional rubber tires. While they are more expensive, they will last longer and save you money in the long run.

Here is how to crown urethane bandsaw tires:First, clean the surface of the tire with rubbing alcohol. This will remove any dirt or debris that could prevent the urethane from bonding properly.

Next, apply a thin layer of adhesive to the surface of the tire. Be sure to use an adhesive that is compatible with urethane. We recommend Loctite 454 Prism Adhesive for this application.

Now it’s time to apply the urethane band. Start in the center of the tire and work your way outwards. Apply even pressure as you go to avoid creating creases or bubbles in the material.

Once you’ve reached the edge of the tire, use a sharp knife to trim away any excess urethane.Allow the adhesive to cure for at least 24 hours before using your bandsaw again. And that’s it!

You’ve successfully crowned your urethane bandsaw tires!

- First, you’ll need to remove the old tires from the bandsaw wheels

- To do this, use a putty knife or other flat tool to pry the tire away from the wheel

- Next, clean the surface of the wheel with a degreaser or alcohol wipes

- This will ensure that the new tires adhere properly

- Now it’s time to install the new urethane tires onto the bandsaw wheels

- Start by stretching one end of the tire over the lip of the wheel

- Then work your way around, using your fingers to press and smooth out any wrinkles in the tire

- 4 Finally, use a roller or some other heavy object to press down on each tire and seat it firmly onto the wheel surface

Bandsaw tire crowning method

How Do You Put a Crown on a Band Saw Tire?

If your band saw tires are worn down, you may need to replace them. You can do this yourself with a few tools and a little know-how. Here’s how to put a crown on a band saw tire:

1. Remove the old tires. First, you’ll need to remove the old tires from the wheels. To do this, loosen the bolts that hold them in place.

Then, use a tire tool or crowbar to pry the tires off of the wheels.2. Clean the wheels. Once the old tires are off, clean the wheels so that there is no dirt or debris on them.

This will help ensure that the new tires adhere properly.3. Install the new tires. Place the new tire on the wheel and then secure it in place with the bolts you loosened earlier.

Make sure that the tire is snug and doesn’t have any gaps between it and the wheel.4. Inflate the new tires . Use an air compressor to inflate your new tires to their proper pressure levels indicated by their manufacturer .

Do Urethane Bandsaw Tires Need Glue?

Bandsaw tires are one of the most important parts of a bandsaw, as they provide the surface that the blade runs against. There are two main types of bandsaw tires: urethane and rubber. While both types of tires have their own advantages and disadvantages, urethane tires are generally considered to be superior to rubber tires in terms of durability and performance.

One of the main advantages of urethane tires is that they do not require glue to stay in place on the wheel. This is because urethane is a much more flexible material than rubber, so it can conform to the shape of the wheel without needing to be glued down. This makes changing urethane tires much easier than rubber tires, as you don’t need to worry about applying or removing glue from the tire surface.

Urethane also has better resistance to heat and chemicals than rubber, meaning that it will last longer before needing to be replaced.The only real downside to urethane tires is that they can be more expensive than rubber tires. However, considering their superior performance and longevity, they are often worth the extra investment.

What Adhesive Works for Bandsaw Tires?

There are a few adhesives that work well for bonding bandsaw tires to wheels. We have had good success with Bostik’s Best Adhesive, Loctite Power Grab Express Adhesive, and 3M Super 77 Multipurpose Adhesive.Bostik’s Best is a premium grade adhesive that has been formulated for high strength bonding.

It provides a strong initial grab and sets up quickly, making it ideal for bonding bandsaw tires. Loctite Power Grab Express is a construction adhesive that is designed for quick setting and high bond strength. It can be used on a variety of surfaces, including wood, metal, concrete, and ceramic.

3M Super 77 is an all-purpose adhesive that can be used on a variety of materials, including paper, cardboard, fabric, and plastic film.

Why are Bandsaw Wheels Crowned?

Bandsaw wheels are crowned in order to keep the blade tracking in the center of the wheel. If the blade were to track off-center, it would quickly wear down both the side of the wheel and the blade, causing reduced cutting performance and premature failure.

Credit: woodworker.com

Bandsaw Wheel Rubber Replacement

If your bandsaw’s wheels are looking worn out, it might be time to replace the rubber. This is a fairly easy process that anyone can do at home with a few simple tools. Here’s how to do it:

1. First, you’ll need to purchase some new rubber. You can find this at most hardware stores or online. Make sure you get the right size for your wheels!

2. Once you have the new rubber, use a sharp knife to cut off the old rubber from the wheels. Be careful not to damage the metal beneath.3. Next, clean off any dirt or debris from the surface of the wheel using a rag and some rubbing alcohol.

4. Now it’s time to attach the new rubber. Start by applying a generous amount of glue around the edge of one side of the wheel. Then, firmly press on one end of the new piece of rubber, holding it in place until the glue dries (this should only take a few minutes).

Bandsaw Drive Wheel Rubber

If you own a bandsaw, chances are you will eventually need to replace the drive wheel rubber. The drive wheel is the large wheel that sits at the back of the saw and drives the blade. Over time, the rubber on this wheel can become hardened and cracked, which can cause it to slip or even break.

There are a few things to keep in mind when replacing drive wheel rubber. First, make sure you get the right size for your saw. Second, be sure to install it correctly – if it’s not tight enough, it can come off while you’re using the saw.

Finally, be careful not to over-tighten the bolts – this can strip the threads or break thewheel.With a little care and attention, replacing your bandsaw’s drive wheel rubber is a fairly easy task that anyone can do!

How to Trim a Bandsaw Tire

If your bandsaw’s tires are looking worn, it’s time to give them a good trimming. Here’s how to do it:1. Remove the bandsaw from its stand and unplug it.

2. Use a screwdriver or Allen wrench to remove the blade guard.3. Loosen the tension on the blade by turning the tensioning knob counterclockwise.4. Remove the old tire by prying it off with a flat-head screwdriver or other tool.

Be careful not to damage the wheel in the process.5. Cut a new tire to size out of vulcanized rubber (you can find this at most hardware stores). Make sure that it is slightly larger than the old tire so that it will fit snugly on the wheel.

+ 6Use super glue or another type of strong adhesive to attach the new tire to the wheel, being careful not to get any glue on the part of the wheel that contacts the blade (this could cause premature wear). Allow plenty of time for the glue to dry before moving on to Step 7. If you’re having trouble getting one side ofthe new tireto adhere, try heating up that part ofthe wheel with a heat gun or hair dryer; this will help softenthe surface and make for a stronger bond.

.7Oncethe glue is completely dry, re-installthe blade and tighten its tension usingthe tensioning knob clockwise until there is no slack inthe blade (but don’t overtighten).8 Re-attachthe blade guardand put yourbandsaw backon its stand..

And that’s all there isto it!

Conclusion

How to Crown Urethane Bandsaw TiresIf your bandsaw is producing less than perfect cuts, it might be time to crown the urethane tires. This simple adjustment can make a big difference in cutting performance.

Here’s how to do it:First, loosen the bolts that hold the urethane tires in place. Next, use a flathead screwdriver to slightly pry up on one side of the tire until you see a small gap open up between the tire and wheel.

Do the same on the other side of the tire.Now gently push down on the center of the tire until you hear a popping noise. This indicates that the tire has seated itself properly on the wheel.

Once you’ve done this, tighten down all of the bolts and check your work by spinning the wheel by hand—it should spin smoothly without any wobbling.

How to Buy Tires from China

If you’re looking to buy tires from China, there are a few things you need to keep in mind. First of all, you need to make sure that the company you’re buying from is reputable. There are a lot of fake companies out there that will try to sell you counterfeit or inferior products.

Do your research and make sure you’re buying from a reputable source. Secondly, you need to be aware of the different types of tires available. There are passenger car tires, light truck tires, and off-road tires, so make sure you know what type of tire you need before making your purchase.

Finally, be prepared to pay shipping costs. Tire sizes can vary greatly between manufacturers, so it’s important to get the right size for your vehicle. Shipping costs can also add up, so be sure to factor that into your budget when making your purchase.

- Identify the type of tires you need

- There are many different types of tires, each designed for a specific purpose

- You will need to know the size, load rating, and speed rating of the tires you need before you can purchase them

- Research tire manufacturers in China

- Once you know the specifications of the tires you need, you can begin looking for Chinese manufacturers that produce them

- Be sure to read reviews and compare prices before choosing a manufacturer

- Place an order with a Chinese tire manufacturer

- Once you have selected a manufacturer, you will need to place an order for the tires you need

- Most manufacturers will require payment in advance before shipping the tires

- Wait for your shipment of tires to arrive from China

- Depending on the shipping method chosen, it may take several weeks for your shipment to arrive from China

CHEAP CHINESE TIRES REVIEW SHOULD I BUY THEM?

China Tire Brands

There are many tire brands that come from China. Some of the most popular brands include: Advance, Aeolus, Apollo, Falken, Giti, Goodyear, Hankook, and more. These tires are known for their quality and performance.

They offer a variety of sizes and tread patterns to choose from. Whether you need all-season or winter tires, you can find a great set of tires from a Chinese brand.

Credit: www.youtube.com

Are Tires from China Any Good?

There’s a lot of debate surrounding tires from China. Some people swear by them, while others have had less than ideal experiences. So, are tires from China any good?

It depends. There are some high-quality tire manufacturers in China, such as Linglong and Double Coin. However, there are also some lower-quality brands that produce subpar products.

That being said, it’s important to do your research before purchasing tires from China. Read reviews and compare prices to ensure you’re getting a good product for your money.If you’re looking for a quality set of tires at an affordable price, then purchasing from China may be a good option for you.

Just be sure to do your homework first!

What is the Best Chinese Tire Brand?

There are many tire brands that manufacture tires in China. Some of the most popular Chinese tire brands include: Linglong, Double Coin, Sailun, and Giti. These brands all offer a variety of different types of tires that are suitable for a wide range of vehicles.

Linglong is one of the largest tire manufacturers in China. The company offers a wide range of passenger car tires, light truck tires, commercial truck tires, off-road tires, and motorcycle tires. Linglong also has a strong presence in the global market with products being exported to over 130 countries worldwide.

Double Coin is another leading Chinese tire manufacturer that specializes in producing radial tyres for passenger cars, light trucks, commercial trucks, and buses. The company’s products are exported to over 80 countries around the world.Sailun is a Chinese tire brand that focuses on manufacturing high-quality all-steel radial tyres for passenger cars, light trucks, SUVs, and vans.

The company’s products are exported to more than 120 countries globally.Giti is a leading Chinese manufacturer of passenger car tyres, truck and bus tyres as well as off-road tyres. The company’s products are exported to over 130 countries across six continents.

All four of these brands offer reliable and high-quality products that are suitable for a variety of vehicles. When choosing the best Chinese tire brand for your needs, it is important to consider what type of vehicle you will be using the tires on as well as your budget.

Are Tires Imported from China?

There is no definitive answer to this question as it largely depends on the specific tires in question and where they are being sold. However, it is worth noting that a large number of tires are indeed imported from China. This is because tire manufacturing is one of China’s many strengths and the country has been able to produce high-quality tires at very competitive prices.

As a result, many tire brands – both big and small – source their tires from China. So, if you’re looking to buy new tires, it’s quite likely that at least some of the options you’re considering will be imported from China. Of course, there are also plenty of other tire-producing countries out there, so it’s definitely worth doing your research before making any final decisions.

Are Michelin Tires Made in China?

Yes, Michelin tires are made in China. In fact, Michelin has been manufacturing tires in China since 1984, when it opened its first factory in the country. Today, Michelin has four factories in China, located in the cities of Shenyang, Tianjin and Wuxi.

Together, these factories produce more than 10 million tires per year for the Chinese market.Michelin is not the only tire company with a presence in China. In recent years, a number of other international tire brands have also set up production facilities in the country.

This is due to a number of factors, including the large and growing size of the Chinese market, as well as favorable government policies towards foreign investment.

Conclusion

Planning to buy tires from China? Here’s what you need to know!First, research the quality of the tires you’re interested in.

There are many counterfeit products on the market, so it’s important to make sure you’re getting a good product.Second, find a reputable seller. Once you’ve found a few potential sellers, compare prices and reviews to choose the best one.

Third, pay attention to shipping costs. Tires can be heavy and bulky, so shipping can be expensive. Make sure to factor in shipping costs when comparing prices between sellers.

Fourth, be prepared for a long wait. Shipping from China can take several weeks, so don’t expect your tires to arrive immediately.Finally, enjoy your new tires!

With a little bit of planning and research, buying tires from China can be a great way to save money on your next purchase.

How to Cut Fenders for Bigger Tires

Have you ever been driving down the road, minding your own business, when all of a sudden a huge puddle appears out of nowhere? Or maybe you hit a pot hole that was hidden by leaves and now your tire is shredded. These are just a few examples of why it might be necessary to cut your fenders.

If you have ever wondered how to cut fenders for bigger tires, then this blog post is for you!

- Decide how much you want to cut off the fenders

- This will depend on the size of the tires you are planning to install

- Use a measuring tape to measure and mark where you will make your cuts

- Cut along the lines you have marked, using a jigsaw or similar tool

- Test fit your new tires to make sure they clear the newly cut fenders

- If necessary, trim off more material until they fit properly

Cutting truck fenders (to make more tire clearance)

How Do I Cut My Truck for Bigger Tires?

There are a few different ways that you can go about cutting your truck for bigger tires. The most popular method is to simply cut the fenders. This will allow you to fit much larger tires on your truck without any rubbing or clearance issues.

Another way to achieve this is by installing body lift kits. This will raise the body of your truck up, giving you more room to fit larger tires. Keep in mind that both of these methods will require some additional work in order to maintain a clean and finished look.

How Do You Cut Inside Fenders?

Assuming you would like tips on how to cut inside fenders:One of the most difficult and tedious bodywork jobs is cutting out fender wells. It’s a job that’s often put off because it seems so daunting, but with the right tools and a little bit of patience, it’s not as bad as it looks.

Here are a few tips on how to cut inside fenders:-Start by removing any trim or molding that might be in the way. This will give you a clear area to work with.

-Use a razor knife or something similar to score along the line where you want to make your cut. This will help prevent the material from chipping or cracking when you start cutting.

-Now it’s time for the power tools.

A small handheld circular saw is ideal for this job. Start by making shallow cuts along your scored line until you’ve gone all the way through the material. Be careful not to go too deep, or you’ll damage whatever is on the other side of the fender well.

-After you’ve made your initial cuts, switch to a jigsaw to finish up the job. This will allow you to make tighter turns and get into those hard-to-reach places. Again, be careful not to damage anything on the other side of the fender well.

How Do You Cut Front Fenders?

Assuming you mean how to cut and replace front fenders on a car:Removing the old fender is relatively easy, especially if it’s already been damaged. First, remove all of the bolts holding the fender in place.

There should be four bolts on the top of the fender near the hood, and two on each side near the door. Once these are removed, the fender should pull right off.Installing the new fender is a bit more difficult, but still not too complicated.

Start by lining up the new fender with the holes where the old one was attached. Once it’s in place, bolt it down using the same screws that held on the old fender. You may need to adjust it a bit to get everything lined up perfectly before tightening all of the bolts down.

Do You Need to Cut for Fender Flares?

If you’re looking to install fender flares on your vehicle, you might be wondering if you need to cut the factory fenders to do so. The good news is that in most cases, you won’t need to cut anything at all. Many fender flare kits come with hardware that bolts directly onto the existing fenders, making installation a breeze.

However, there are some circumstances where cutting may be necessary. If your vehicle has very wide tires, for example, or if you’re going for a particularly aggressive look, cutting the factory fenders may be the best way to go. Keep in mind that this will require more work and some specialized tools, so it’s not a decision to be made lightly.

But if you’re up for the challenge, it can definitely give your car a unique look.So there you have it – in most cases, no cutting is required when installing fender flares. But if you’ve got a specific vision for your car, don’t let that stop you from going for it!

Credit: offroading.com

Best Tool to Cut Fenders

If you’re looking to cut your fenders, there are a few things you’ll need to consider. What kind of car do you have? What is the make and model?

What year is it? These are important factors to think about when choosing the best tool to cut your fenders.There are a few different ways that you can go about cutting your fenders.

You can use a power drill, a sawzall, or even a Dremel tool. Each has its own advantages and disadvantages. The power drill will be the quickest way to get the job done, but it can be tricky to control and may cause more damage than necessary.

The sawzall will take longer, but it’s much more precise and won’t damage the surrounding area as much. The Dremel tool is somewhere in between, taking slightly longer than the power drill but being more precise than the sawzall.ultimately, it’s up to you which tool you use to cut your fenders.

Just make sure that you take into consideration what kind of car you have and what will work best for your particular situation.

Fender Roller

A fender roller is a tool that allows you to roll the fenders on your car. This can be helpful if you have installed new wheels and tires that are wider than the stock ones, or if you just want to give your car a more aggressive stance. Fender rolling is not difficult, but it does require some patience and attention to detail.

Here’s a step-by-step guide to help you get started.First, park your car on a level surface and engage the emergency brake. You’ll also want to remove any hubcaps or wheel covers so that you have clear access to the fender lip.

Next, use a tape measurer or ruler to mark the center of the fender lip. This will be your starting point.Now it’s time to start rolling the fender lip.

Begin at the center point that you marked earlier, and slowly work your way outwards. Use even pressure as you go, and try not to apply too much force – you don’t want to damage the paint or bodywork. As you reach the end of the fender lip, gently bend it downwards so that it sits flush with the tire.

Repeat this process on the other side of the car, and then take it for a test drive! With proper care and attention, rolled fenders can last for years without issue.

Fender Trimming near Me

If you’re looking for a great place to get your fender trimmed, look no further than your local body shop! Most body shops offer this service and can usually do it while you wait. This is a great way to improve the look of your car and make it stand out from the crowd.

Conclusion

If you’re looking to add some bigger tires to your ride, you’re going to need to cut the fenders. It’s not a difficult process, but there are a few things you’ll need to keep in mind. First, make sure you have the right tools for the job.

You’ll need a good pair of scissors and a sharp knife. Next, take your time and measure twice before you cut. Once you’ve made your cuts, test fit the tires to make sure everything looks good.

Finally, enjoy your new found clearance and go hit the trails!

How to Cut a Tire off a Rim

If you’ve ever had a flat tire, you know the frustration of dealing with a deflated wheel. Most people take their car to a mechanic to have the tire replaced, but this can be an expensive fix. If you’re looking to save some money, you can remove the tire from the rim yourself.

It’s a fairly simple process that only requires a few tools.

- First, you will need to gather all of the necessary tools

- You will need a wire cutters, a hammer, and a chisel

- Next, you will need to remove the valve stem from the tire

- To do this, simply use the wire cutters to snip off the stem

- Once the valve stem has been removed, deflate the tire completely using a air compressor or by letting all of the air out manually

- Now it’s time to start cutting! Use your hammer and chisel to start pounding away at the edge of the tire where it meets the rim

- Keep working your way around until eventually the entire tire has been separated from the rim

The best and safest way to remove tire from Rim for scrap

What Can I Use to Cut a Tire off the Rim?

If you need to cut a tire off the rim, you can use a variety of tools. A sharp utility knife or box cutter can work, but it’s best to use a dedicated tire iron. You can find these at most auto parts stores.

Place the tip of the tire iron under the lip of the tire and pry it up. Work your way around the circumference of the tire until it pops off the rim. If the tire is particularly stubborn, you may need to use a hammer to tap on the end of the tire iron.

What Can I Use to Cut a Tire?

There are a few things you can use to cut a tire. The most common and effective way is to use a utility knife. You can also use a saw, but it will take longer and be more difficult.

If you have a power drill, you can use a metal cutting bit to make the job easier. Whatever method you choose, be very careful not to damage the rim of the tire.

What is the Easiest Way to Get a Tire off a Rim?

It is usually easiest to use a tire lever to remove a tire from a rim. First, insert the lever under the edge of the tire and pry it up. Then, work your way around the circumference of the tire until it is completely removed from the rim.

How Do You Get a Tire off a Rim Without a Machine?

If you find yourself in a situation where you need to remove a tire from a rim but don’t have access to a machine, there are a few methods you can try. With the right tools and some patience, you should be able to get the job done.The most important tool you’ll need is a tire lever.

This is a long, thin piece of metal or plastic that’s designed specifically for removing tires from rims. You’ll also need something to prop up the tire so you can work on it more easily – an old piece of wood or a block of concrete will do the trick.Once you have your tools ready, start by loosening the bead of the tire from the rim.

This can be tricky, and may take some trial and error before you get it right. Once the bead is loose, insert your tire lever under it and pry upwards gently until the tire pops off the rim.If all goes well, this should leave you with just the inner tube exposed.

To remove it completely, simply deflate it and pull it out through one of the openings in the rim. Now all that’s left is to put everything back together again!

Credit: www.reddit.com

Can You Cut a Tire off a Rim

When it comes to changing a tire, most people know that you can’t just cut the tire off the rim. However, there are some situations where you may need to remove a tire from a rim, such as when you’re changing a flat tire or getting new tires. So, how do you cut a tire off a rim?

First of all, you’ll need some basic tools, including a sharp knife or razor blade. You’ll also need a strong pair of pliers. Start by deflating the tire completely so that it’s easier to work with.

Then, use your knife or razor blade to score around the circumference of the tire at the point where it meets the rim.Next, insert your strong pair of pliers into the scored line and twist them back and forth until the tire pops off the rim. If necessary, use your knife or razor blade to help pry the Tire away from The Rim .

Finally , dispose of The Tire properly .

How to Get a Tire off a Rim by Hand

There are a few reasons why you might need to remove a tire from a rim by hand. Maybe you got a flat tire and don’t have access to a air compressor or other tools. Or maybe you’re changing tires and don’t want to wait for a service station.

Whatever the reason, it’s not as difficult as it may seem. With a little elbow grease, you can get that tire off in no time.Here’s what you’ll need:

– A flat surface (a driveway or sidewalk will do)

– A piece of wood or metal at least 2 feet long

– A Phillips head screwdriver (optional)

– Something to wedge under the tire (a rock or brick will work)First, remove the wheel cover, if there is one. Then use the screwdriver to loosen the lug nuts about half a turn each.

You don’t need to remove them completely, just enough so they’re loose. Next, position the board or piece of metal under the center of the tire. Wedge whatever you’re using under the other end of the board so it doesn’t slip out when you start prying up on the tire.

Now it’s time to start prying! Put your weight into it and slowly work your way around the circumference of the tire until it pops off the rim. If it’s really stuck, try hitting the board with something heavy like a rock or hammer (wrapped in cloth first).

Once the tire is free, put all your lug nuts back on loosely so you don’t lose them and then put your wheel cover back on if applicable. That’s it – now you know how to remove a tire from a rim by hand!

Cut Tire off Rim Sawzall

If you’ve ever had a flat tire, you know the frustration of trying to remove the tire from the rim. The traditional method is to use a jack to lift up the car and then use a lug wrench to loosen the lug nuts. But what if your lug nuts are too tight or your jack doesn’t work?

You can always resort to the brute force method – using a sawzall to cut the tire off the rim.This may seem like a crazy idea, but it’s actually not that difficult. Just be sure to wear eye protection and gloves, and have a few rags handy to clean up the mess.

Here’s how it’s done:1. Position the sawzall blade so it’s perpendicular to the tire tread. You don’t want to damage the wheel, so be careful not to angle the blade too much.

2. Start cutting through the tire at one end of the tread. It’s important to keep a steady hand as you cut through all four layers of rubber. If you need help, rest your elbow on something solid like your car door or fender.

3. Continue cutting until you’ve gone all around the circumference of the tire. Once you’re finished, gently pull on each side of the cut tire until it comes off completely fromthe rim..

4 If there are any stubborn pieces remaining, use pliers or another toolto pry them loose.. 5 And that’s it!

Conclusion

If you’ve ever had a flat tire, you know the drill. You have to remove the tire from the rim so you can patch or replace it. It’s not as difficult as it sounds, and with a little practice, you can do it in minutes.

Here’s how to cut a tire off a rim:First, loosen the lug nuts on the wheel. Then, use a jack to lift up the car so you can work on the tire.

Next, use a pry bar to loosen the bead of the tire from the rim. Once the bead is loose, use a utility knife to cut through the sidewall of the tire. Finally, pull the tire off of the rim and dispose of it properly.

With these simple steps, you’ll be able to change a flat tire in no time!

How to Deflate a Tire Fast

When you get a flat tire, it’s important to know how to change it quickly. It’s also important to know how to deflate a tire fast. There are a few different ways to do this, and the best method will depend on the type of tire you have.

If you have a tubeless tire, you can use a special tool to puncture the tire and release the air. If you have a tube-type tire, you can use a screwdriver or other sharp object to puncture the tube and release the air. You can also use a compressor or CO2 cartridge to quickly release the air from your tires.

How to Quickly Deflate A Car, Truck or SUV Tire

- The following steps will detail how to deflate a tire quickly:1

- Locate the valve stem on the tire

- This is the small black or silver knob sticking out of the tire

- Unscrew the cap from the valve stem

- Place the end of a tire gauge onto the valve stem and press down to release air from the tire

- You may need to do this multiple times to fully deflate the tire

- Once you have released all of the air from the tire, screw the cap back onto the valve stem to prevent more air from entering

How to Deflate a Tire Without Tools

It’s happened to all of us. You’re out on the road, and you get a flat tire. But don’t worry, changing a tire is easy, and you don’t even need any tools.

Here’s how to do it:First, find something to prop up your car. A rock or a piece of wood will work fine.

Then, loosen the lug nuts on your wheel with your hands. Once they’re loose, remove the wheel and set it aside.Now take a look at the tire.

You’ll see a valve stem sticking out of it – that’s what you need to deflate the tire. To do that, simply use your thumb and index finger to pinch the valve stem and release the air inside the tire. Keep doing this until the tire is completely flat.

Now all that’s left to do is put the wheel back on and tighten the lug nuts. And that’s it! You’ve successfully changed a flat tire without any tools whatsoever.

How to Puncture a Car Tire Silently

If you’re planning on puncturing a car tire silently, there are a few things you’ll need to take into account. First, you’ll need to find the right type of object to use for puncturing the tire. A sharp metal object like a screwdriver or ice pick will work well.

You’ll also need to be sure that the object you’re using is long enough to reach the inner wall of the tire. Otherwise, you may end up making too much noise when trying to puncture the tire.Once you have your materials ready, it’s time to get started.

Begin by positioning yourself next to the tire you want to puncture. Then, insert the sharp object into the side of the tire at a 45 degree angle. Apply pressure and push the object through the sidewall of the tire until it comes out on the other side.

If done correctly, this should cause minimal noise and won’t alert anyone nearby that something is happening.Now that you know how to puncture a car tire silently, put this knowledge to good use! This can come in handy if you ever need to disable a vehicle without drawing attention to yourself.

How to Deflate a Tire Bike

Assuming you have a bike with tires that can be deflated:To deflate a tire on a bike, you will need a valve stem cap remover and a hand pump. First, use the valve stem cap remover to take off the cap from the valve stem.

Next, place the hand pump on the valve stem and start pumping air out of the tire. Once the tire is fully deflated, put the valve stem cap back on and you’re done!

How to Let Air Out of Tire Without Screwdriver

It’s happened to all of us. You’re out on the road and you get a flat tire. The first thing you think is “how am I going to get this air out without a screwdriver?”

Well, here’s how.All you need is a pen or a sharp object that can fit into the valve stem on your tire. Stick it into the valve and push down.

You may have to do this several times to get all the air out. Once the air is out, remove the object and put on your spare tire.So there you have it!

Now you know how to let air out of your tire without a screwdriver.

How to Deflate Tyres at Petrol Station

It’s a hot summer day and you’re out on the open road, enjoying the feel of the wind in your hair. But as the sun beats down, you start to notice that your tyres are looking a bit low. You pull into the next petrol station and decide to top them up.

But how do you know how much air to put in? And what’s the best way to go about doing it?Here’s a quick guide on how to deflate tyres at petrol stations:

1. Check your tyre pressure first. Use a tyre pressure gauge to check that your tyres are sitting at the correct pressure. If they’re not, then you’ll need to adjust accordingly.

2. Find an air compressor. Most petrol stations will have an air compressor that you can use to fill up your tyres. Simply attach the hose and turn it on.

3. Fill up your tyres slowly. Don’t try and fill them up too quickly as this could cause damage or uneven wear patterns. Instead, fill them up slowly until you reach the desired pressure level.

Credit: www.amazon.com

How Do You Let Air Out of a Tire Slowly?

Assuming you need to let air out of a tire slowly for some reason, there are a few ways to go about it. If you have access to an air compressor, you can use the release valve on the compressor head to bleed off pressure gradually. If you don’t have an air compressor handy, or if the release valve is damaged, you can remove the valve stem cap and press down on the stem with a small tool to release pressure gradually.

Finally, if all else fails, you can puncture the tire with a sharp object like a nail or screwdriver and let the air hiss out slowly that way. Whatever method you choose, be careful not to let too much air out at once or you’ll risk damaging your tire.

How Long Does It Take to Manually Deflate a Tire?

It takes about 5-10 minutes to manually deflate a tire. You will need a tire gauge and an air compressor. First, use the tire gauge to check the pressure of the tire.

If it is above 30 psi, then you can start to let the air out. Use the air compressor to slowly release the air from the tire. Once the pressure is below 30 psi, you can remove the tire gauge and finish letting the air out by pressing on the center of the valve stem with your thumb.

What Can You Use to Deflate a Tire?

There are a few different ways that you can deflate a tire. You can use a tire iron to remove the valve stem cap and then use a tire lever to press on the valve stem in order to release the air. Alternatively, you could use a power drill with a deflation attachment.

Another option would be to use a CO2 cartridge to quickly release all of the air from the tire.

Is It a Crime to Deflate Someone’S Tires?

It is not a crime to deflate someone’s tires. However, depending on the circumstances, it could be considered malicious mischief or criminal damaging. For example, if you were to deliberately let the air out of someone’s tires in order to disable their vehicle, that would likely be considered malicious mischief.

Likewise, if you were to slash someone’s tires, that would be considered criminal damaging. In either case, you could potentially face charges if caught and convicted.

Conclusion

It’s happened to all of us at some point – you’re driving along and suddenly, you have a flat tire. It can be a pain to deal with, but it doesn’t have to be. With a few simple steps, you can deflate your tire fast.

First, find a safe place to pull over. Once you’re stopped, put on your hazard lights so that other drivers will know to beware. Next, locate your jack and spare tire.

If you don’t know where they are, consult your car’s owner’s manual.Now it’s time to get down to business. First, loosen the lug nuts on your flat tire using the wrench (most cars have one in the trunk).

Once they’re loose, use the jack to lift up the car so that the flat tire is off the ground. Now simply remove the lug nuts and wheel and put on the spare tire. Tighten everything back up and lower the car back down.

You’re now ready to hit the road again!

How to Cut a Bumper for Tires

Any car enthusiast knows that one of the most important things to keep in check on your vehicle is the alignment of the tires. This is because misaligned tires can cause a number of problems, ranging from decreased fuel efficiency to premature wear and tear. And while there are a number of ways to tell if your tires are out of alignment – such as uneven tire tread or steering that pulls to one side – sometimes the only way to know for sure is to get an alignment check from a professional.

But what if you’re not able to get your car aligned right away? One temporary solution is to cut your bumper for tires.

- Park your car on a flat surface and place jack stands under the frame to support it

- Measure the distance from the ground to the bottom of the bumper

- This will be the height you need to cut off the bumper

- Draw a line across the bumper at the desired cutting point using a pencil or marker

- Cut along the line with a saw, being careful not to damage any other parts of the car

- Test fit your new tires and make sure they clear the bottom of the bumper before driving off!

THE RIGHT WAY TO TRIM YOUR BUMPER!

What Can I Use to Cut My Bumper?

When it comes to cutting your bumper, there are a few different options that you can choose from. You can either use a jigsaw, a handheld saw, or even a power drill with the right attachment.If you’re going to be using a jigsaw, then you’ll want to make sure that you have a sharp blade and that you’re following the lines of your template as closely as possible.

It’s also important to go slowly and steadily when cutting with a jigsaw so that you don’t end up with any uneven edges.A handheld saw can also be used to cut through your bumper, but it’s important to be extra careful when doing so. Make sure that the blade is nice and sharp before starting, and take your time while cutting so that you don’t accidentally slip and damage the surrounding area.

Finally, if you have access to a power drill then you can actually use this tool to make the cuts for your bumper. All you need is an attachment called a hole saw, which is specifically designed for making clean cuts in plastic and other materials. Just make sure that the hole saw is the right size for the job before getting started.

How Do You Cut Fenders?

When it comes to fender cutting, there are a few different ways that you can go about doing it. The most common method is to use a sawzall or an oscillating tool with a metal-cutting blade. You’ll want to make sure that you have a good, sharp blade before starting this project.

Another option is to use a plasma cutter. This will give you a cleaner cut and is generally quicker than using a sawzall. However, it does require more setup and you’ll need to be careful not to overheat the metal.

If you’re not comfortable with either of these methods, you can always take your car to a professional who can do it for you. Just be prepared to pay for their services.

How Do You Shape a Bumper?

Bumpers are one of the most important parts of a car, yet often go overlooked. They are designed to protect the car and its occupants in the event of a collision, and as such need to be strong and durable. But how exactly do you shape a bumper?

The first step is to create a mold for the bumper. This is usually done by combining two pieces of wood or metal into a rectangular shape, with the desired dimensions for the bumper. Once the mold is created, it needs to be covered in something that will allow the plastic or fiberglass to adhere to it – this is typically silicone or wax.

Once the mold is ready, it’s time to start shaping the bumper. This is usually done by layering sheets of plastic or fiberglass over each other until the desired thickness is achieved. The number of layers will depend on how strong you want the bumper to be – typically, 4-5 layers should suffice.

Once all the layers are in place, they need to be bonded together. This can be done with epoxy resin, which will create a strong and durable bond between all the layers. Once cured, your bumper is now ready for installation!

How Do You Cut a Fibreglass Bumper?

Assuming you would like tips on how to cut a fibreglass bumper:One option is to use a jigsaw with a fine-toothed blade designed for cutting metal. Another is to use a rotary tool with a abrasive cutting disc.

To make the cuts, start by marking the areas you need to remove with painter’s tape. Then, using either the jigsaw or rotary tool, slowly and carefully cut along the lines. Be sure to wear protective gear, such as gloves and safety glasses, when working with power tools.

Once you’ve made the cuts, smooth out any rough edges with sandpaper. And that’s it! With a little patience and care, you can easily cut a fibreglass bumper yourself.

Credit: trail4runner.com

How to Cut Bumper for Exhaust

If you’re looking to cut your bumper for an exhaust, there are a few things you’ll need to consider. First, you’ll need to make sure that the cutting is done symmetrically so that your car looks balanced. Secondly, you’ll want to be extra careful not to damage the paint or underlying metal when cutting through the bumper.

Assuming you have all the necessary tools ready, begin by measuring out where you want to make your cuts. Once you have your lines marked, use a drill to create pilot holes at each corner of the rectangle you’re planning to cut out. This will help prevent your saw from slipping as you make your cuts.

Next, use a jigsaw fitted with a metal-cutting blade to slowly and carefully cut along your lines. Be sure to wear gloves and eye protection while doing this step. Once the cutting is complete, use a file or sandpaper to smooth out any rough edges around the hole.

Now it’s time to install your exhaust tips! If they don’t fit snugly into the hole you’ve cut, trim them down as needed until they do. Finally, stand back and admire your handiwork – with a little effort, you’ve now got an stylish exhaust setup!

Best Tool for Cutting Plastic Bumper

If you’re looking for the best tool for cutting plastic bumper, look no further than the Dremel Ultra-Saw. This powerful little saw is perfect for quickly and easily cutting through plastic bumper material. It’s also great for other materials like wood, metal, and tile.

The Ultra-Saw has a 3-position handle that makes it easy to maneuver and control, and its compact size means it can be used in tight spaces. Plus, its variable speed feature allows you to adjust the blade speed to match the material you’re cutting.

Bumper Cutting Tool

A bumper cutting tool is a power tool that is used to cut through the bumper of a car. This type of tool is typically used by mechanics or body shops in order to remove the bumper from a car so that it can be repaired or replaced. The cutter itself is usually a handheld device that looks similar to a circular saw, and it has a blade that is specifically designed for cutting through plastic and metal.

Bumper cutting tools can be powered by either electricity or compressed air, and they are typically very easy to use. In most cases, all you need to do is line up the blade with the edge of the bumper and then start the engine. The tool will do the rest of the work for you.

Conclusion

If you’re looking to cut a bumper for tires, there are a few things you’ll need to keep in mind. First, you’ll need to make sure that the area you’re cutting is clean and free of debris. Second, you’ll want to use a sharp knife or razor blade to make your cuts.

Third, be sure to measure twice and cut once – you don’t want to end up with an uneven cut. Finally, when cutting the bumper, be sure to leave enough material so that it can be reattached later if needed.

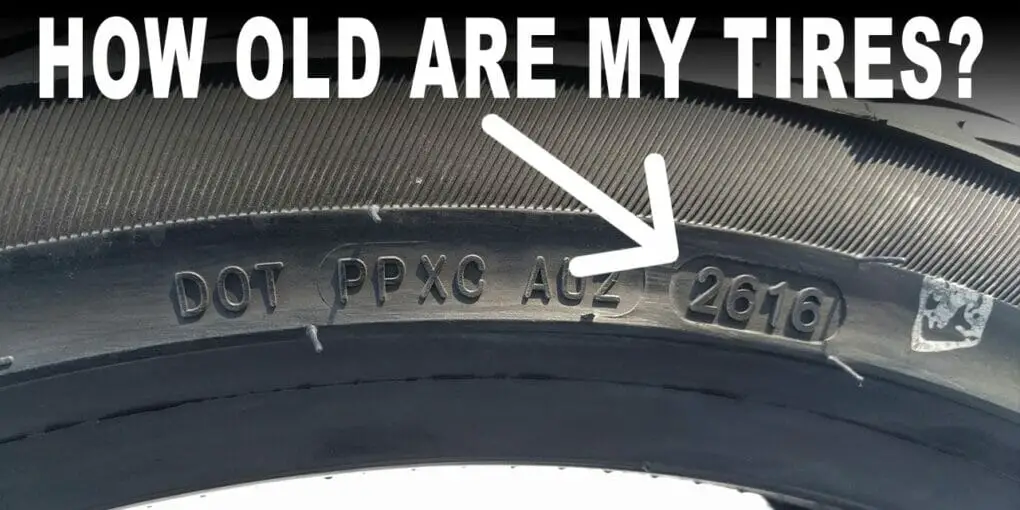

How to Check Expired Tires

If you’re like most people, you probably don’t think about your tires until there’s a problem. But did you know that tires have a limited lifespan? Even if they look fine on the outside, they may be past their prime.

That’s why it’s important to know how to check expired tires.Here are four things to look for when checking your tires:

1. The sidewall of the tire should have the date code stamped on it.

This code will tell you when the tire was made.

2. Look for cracks or cuts in the sidewall of the tire. These can weaken the tire and cause a blowout.

3. Check the tread depth of the tire with a penny. Stick the penny into the tread groove with Lincoln’s head facing down. If you can see all of Lincoln’s head, then the tread is worn down and needs to be replaced.

4. Finally, make sure there is no excessive wear on either side of the tire treads (known as feathering).

- Check the date of manufacture on the tire

- The date is usually located on the sidewall of the tire

- Compare the date to the current month and year

- If the tire is more than six years old, it is considered expired

- Examine the tread depth of the tire using a tread depth gauge

- If the tread depth is less than 1/16th of an inch, the tire needs to be replaced

- Inspect the sidewalls of the tires for any cracks or cuts that are deeper than 1/8th of an inch

- Feel for any bulges in the sidewalls of the tires

- Have a professional examine your tires if you are unsure about their condition

Credit: www.nairaland.com

How Do You Know When a Tire is Expired?

It’s important to know when your tires are expired because driving on expired tires is dangerous. Here are a few ways to tell if your tire is expired:1. Check the DOT code on the sidewall of the tire.

This code has four numbers followed by two letters. The first two numbers indicate the week of the year that the tire was manufactured, and the last two numbers indicate the year. For example, if the DOT code on your tire says 1210, that means it was manufactured in the 12th week of 2010.

2. You can also tell if a tire is expired by its tread depth. Most new tires have a tread depth of 10/32 or 11/32 of an inch. Once the tread depth gets down to 2/32 of an inch, it’s time to replace the tire.

You can check tread depth by inserting a quarter into the tread grooves – if you can see all of Washington’s head, then your tread depth is 4/32 and you need new tires ASAP!3. Another way to tell if your tires are expired is by looking for cracks and cuts in the sidewall or tread area. Expired tires are more susceptible to damage, so if you see any cracks or cuts, it’s time for new tires.

How Many Years the Tire Will Expire?

Most tires have a lifespan of around 10 years. However, this can vary depending on the type of tire, how often it is used and how well it is maintained. For example, off-road tires may only last for 5 years while racing tires can last up to 15 years.

Ultimately, it is important to consult your owner’s manual or the tire manufacturer to get an accurate estimate for how long your specific tires will last.

How old are my tires? // How to check tire age

Tire Expiry Date

We all know that tires have a limited lifespan, but did you know that there’s actually an expiration date for them? Yep, it’s true! Just like food items in your pantry, tires have a shelf life and will eventually go bad.

The question is, how do you know when your tires need to be replaced?Here are a few things to keep in mind:1. Check the sidewall of your tire for the “born-on” date.

This is the date that the tire was manufactured and is typically represented by four digits. The first two digits represent the week of production and the last two digits represent the year. For example, if you see a code that reads “2413,” this means that the tire was made in the 24th week of 2013.

2. Most experts agree that tires should be replaced every six years, regardless of tread depth or other visual indicators.

3. Pay attention to your car’s handling. If you notice any strange vibrations or pulling to one side, it could be time to get your tires checked out (or replaced).

4. Use a penny test to check tread depth. Place a penny upside down in several different spots on each tire – if you can see all of Abraham Lincoln’s head, then it’s time for new rubber!

5 .

Keep an eye on your Tire Pressure Monitoring System (TPMS) light – if it comes on, it could mean low air pressure or another issue with your tires.So there you have it – everything you need to know about tire expiry dates!

Conclusion

If your tires are expired, it’s important to check them to see if they need to be replaced. You can check the expiration date of your tires by looking for a four-digit code on the sidewall of the tire. This code represents the week and year that the tire was manufactured.

For example, a tire with a code of 1210 was made in the 12th week of 2010.If you can’t find this code, or if your tires are more than 10 years old, it’s time to replace them. Additionally, even if your tires aren’t expired, you should still check their tread depth regularly.

You can do this by inserting a penny into the tread groove with Lincoln’s head upside down. If you can see all of Lincoln’s head, your tread depth is less than 2/32nds of an inch and it’s time to replace your tires.

How to Deflate Car Tires at Home

Most people know that it’s important to keep their car tires inflated. But did you know that you can actually save money by inflating your car tires at home? Inflating your own car tires is a great way to save money on gas, and it’s also a good way to be sure that your tires are properly inflated.

Let Air Out of a Tire

- To deflate car tires at home, you will need a tire pressure gauge and an air compressor

- First, use the tire pressure gauge to check the current pressure of your tires

- Next, use the air compressor to slowly release air from your tires until they are at the desired pressure

- Finally, recheck the pressure of your tires with the tire pressure gauge to ensure they are properly inflated

How to Deflate a Tire Without Tools

It’s happened to all of us. You’re out on the road, and you get a flat tire. But don’t worry, changing a tire is easy – even if you don’t have any tools with you.

Here’s how to do it:First, find something to use as a jack. A piece of wood or a rock will work in a pinch.

Then, place the jack under the car at one of the points where the frame meets the ground. Slowly lift the car until the tire is off the ground.Next, use your hands or feet to unscrew the lug nuts that hold the wheel on.

Once they’re loose, remove them completely and set them aside. Now you can pull off the old wheel and put on the new one.Tighten up the lug nuts by hand as much as you can before lowering the car back down onto its tires.

Once it’s back on the ground, use your foot or body weight to finish tightening them up. That’s it – you’re done!

How to Let Air Out of Tire Without Screwdriver

Are you looking for a way to let air out of your tire without using a screwdriver? If so, you’ve come to the right place! There are actually several ways that you can do this, and we’re going to share them all with you today.

One way to let air out of your tire is by using a pin or needle. Simply insert the pin or needle into the valve stem and then turn it counterclockwise until the desired amount of air has been released. Another way to do this is by using a pencil eraser.

Just push the eraser onto the valve stem and twist it until air starts coming out. yet another option is to use a ballpoint pen. Remove the ink cartridge from the pen and then screw it onto the valve stem.

Turn it counterclockwise until air begins escaping.Whichever method you choose, releasing air from your tire without a screwdriver is easy and only takes a few seconds!

How to Let Air Out of Tire Without Gauge

It’s happened to all of us before – you’re driving along and suddenly realize that one of your tires is low on air. If you’re lucky, you have a portable air compressor or an aerosol can of compressed air in your trunk. But what if you don’t have either of those things?

You can’t just keep driving on a low tire, but you also can’t exactly leave your car stranded by the side of the road while you go searching for help. So what do you do?If you find yourself in this situation, don’t worry – there is a way to let air out of your tire without a gauge.

All you need is something sharp (a nail, a screwdriver, etc.) and something to use as a plug (a piece of gum, a wad of paper towel, etc.). Here’s how to do it:1) Use your sharp object to poke a hole in the sidewall of the tire.

The hole doesn’t need to be big – just big enough for air to start escaping from the tire.2) Put your plug material over the hole. This will help prevent more air from escaping than necessary.

3) Let some air out of the tire until it is at the desired pressure. Check your car’s owner manual or look online to find out what the recommended tire pressure should be for your particular vehicle.

How to Puncture a Car Tire Silently

If you’re looking to puncture a car tire silently, there are a few things you can do. First, use a sharp object like a nail or screwdriver. Second, find the right spot on the tire – look for where the metal meets the rubber.

Finally, apply pressure and twist until you’ve made a hole in the tire. And that’s it! With these simple steps, you can puncture a car tire without making any noise.

How to Get Air Out of Tires Quickly

If you’ve ever been driving down the road and suddenly felt your car start to shake, it’s likely because you have air in your tires. While having a little bit of air in your tires is normal, too much air can cause problems. Not only will it make your ride less comfortable, but it can also lead to premature tire wear.

So how do you get rid of the excess air in your tires? The best way is to use a tire gauge to check the pressure and then use a tire inflator to add or remove air as needed. But what if you’re in a hurry and don’t have time to mess with all that?

Here’s a quick and easy way to get the air out of your tires:1. Park your car on level ground and turn off the engine.2. Remove the valve cap from each tire.

3. Place one end of a garden hose over the valve stem on one tire and turn on the water.4. As the water starts flowing into the tire, it will push the air out through the valve stem. Keep an eye on the pressure gauge until it reaches zero (or close to zero).

Credit: carroar.com

How Do You Let Air Out of Car Tires Fast?

Most people know that car tires should be inflated to the manufacturer’s recommended pressure. But did you know that tire pressure changes with temperature? In fact, for every 10-degree Fahrenheit change in temperature, your tire’s air pressure will change by about 1 PSI.

So, if it’s a hot day and you just checked your tire pressure and it was fine, by the end of the day it could be low.Under-inflated tires not only make your car less fuel efficient, but they can also be dangerous. If you’re ever unsure about your tire’s air pressure, it’s always best to err on the side of caution and add more air rather than letting any out.

Now that we’ve gotten that safety disclaimer out of the way, let’s talk about how to properly deflate a car tire. The first thing you need is a tire gauge. You can pick one up at any auto parts store for a few bucks.

Once you have your gauge, locate the valve stem on your tire and unscrew the cap. Put the tip of the gauge onto the valve stem and press down firmly until you hear or feel air escaping from around the edge of the gauge. This lets you know that it is seated properly.

Now simply hold down on the gauge and release air from your tire until it reaches the desired PSI reading indicated by your vehicle’s placard or owner’s manual (usually between 32-35 PSI). Don’t forget to put the cap back on when you’re finished!

What is the Fastest Way to Deflate a Tire Tube?

There are a few ways to quickly deflate a tire tube, and the best method may depend on the type of tire you have. For example, if you have a tubeless tire, you can use a valve stem remover to loosen the valve stem core and release all the air at once. If you have a traditional tire with an inner tube, you’ll need to remove the wheel from the bike and then use a hand pump or an air compressor to let all the air out of the tube.

Either way, it’s important to know how to properly deflate a tire tube so that you don’t damage the wheel or cause a flat spot on the tire.

How Do You Pop Someones Tires Without Getting Caught?

There are a few ways that you can pop someone’s tires without getting caught. One way is to use a tire puncture device. This is a tool that you can insert into the tire to create a hole.

Another way is to use a nail or screw. You can simply drop this onto the ground in front of the tire and it will puncture the tire when they drive over it.

Is It a Crime to Deflate Someone’S Tires?

Generally speaking, it is not a crime to intentionally deflate someone’s tires. However, there are some circumstances in which tire deflation could be considered a criminal act. For example, if you were to deliberately puncture someone’s tires in order to cause them harm or prevent them from driving, that would likely be considered criminal mischief or vandalism.

Additionally, if you were to let the air out of someone’s tires as part of a prank and they ended up getting into an accident as a result, you could be held liable for any damages or injuries that occurred. So while generally it is not a crime to simply let the air out of someone’s tires, there are some potential consequences that you should be aware of before doing so.

Conclusion

It’s important to know how to deflate car tires at home in case of a flat tire. It’s also a good idea to keep a small compressor in the trunk for emergencies. Here are the steps for deflation:

1. Park your car on a level surface and set the emergency brake.2. Remove the hubcap or wheel cover, if necessary.3. Loosen the lug nuts with a wrench, but don’t remove them yet.

4. Place a jack under the frame of the car and raise it until the tire is off the ground.5. Finish removing the lug nuts and take off the tire.

6 If you have an older model car, use a tire iron to pry out the valve stem cap and then depress the pin inside with your thumb or another object (like a nail).

Newer models usually have Schrader valves that can be depressed with your thumb without having to remove anything first.. Either way, hold onto the tire so it doesn’t fall off when you remove air from it!

For all models- once air starts hissing out, put on your spare tire quickly! Make sure not to over-tightenthe lug nuts when putting everything back – just snug them up until they’re hand tight..

How to Cut Loader Tires

Most loader tires are made of solid rubber and can be cut with a power cutter. However, if the tire is too thick, you may need to use a saw. Always wear gloves and safety glasses when cutting tires.

Start by cutting the tire in half width-wise. Then, cut each half of the tire length-wise into quarters.

- Using a tire cutter, cut the sidewall of the tire from one end to the other

- Repeat this process on the other side of the tire

- Once both sides have been cut, remove the center portion of the tire using a sharp knife or a Tire Bead Cutter

- Cut along the tread of the tire from one end to the other, being careful not to cut too deeply and damage the rim

- Remove any remaining bits of rubber from the tire using a wire brush or similar tool

DIY/HOW TO CUT A USE LOADER TIRE

What Can You Cut a Tractor Tire With?

When it comes to cutting a tractor tire, there are a few different options that you can go with. For instance, you can use a power saw or a rotary cutter. However, before you start cutting, it is important to make sure that the area around the tire is clear and free of debris.

This will help to prevent any accidents from happening.Once the area is clear, you can begin cutting the tire. If you are using a power saw, it is important to be very careful as you cut through the tough material.

Make sure that you have a firm grip on the saw so that it does not slip and cause any injuries. If you are using a rotary cutter, be sure to follow the manufacturer’s instructions carefully so that you do not damage the machine.After the tire has been cut, remove any sharp edges with sandpaper or a file.

Once this is done, your tractor tire will be ready to use again!

What is the Best Tool to Cut Rubber Tires?

One of the most important tools in any tire shop is a good quality rubber cutter. There are many different types and brands of rubber cutters on the market, but not all are created equal. When it comes to choosing the best tool to cut rubber tires, there are a few things you need to keep in mind.

First and foremost, you need to make sure that the cutter you choose is designed specifically for cutting rubber tires. Many general-purpose knives and scissors can damage or even destroy a tire if used incorrectly. Second, you need to consider the size of the tires you’ll be working with.

Some cutters are only meant for smaller passenger car tires while others can handle larger truck or tractor tires. Make sure to get a cutter that’s appropriate for the size of tires you’ll be dealing with.Third, take into account what type of blade is best suited for cutting rubber.

Some blades are made from harder materials like carbon steel or tungsten, while others use softer metals like aluminum or brass. The hardness of the blade will determine how easily it can slice through tough rubber without dulling too quickly. fourth, pay attention to how easy (or difficult) the cutter is to use.

If you’re constantly having to adjust your grip or fight with the tool, it’s going to make your job a lot harder than it needs to be. Choose a cutter that feels comfortable in your hand and is easy to control.fifth and finally, don’t forget about safety when choosing a tire cutter!

Always opt for a model with some sort of guard around the blade to protect your fingers (and anyone else who might come in contact with the tool). And make sure that the blade itself is securely locked into place when not in use – you don’t want it accidentally slipping out and causing injury.With all these factors in mind, let’s take a look at three popular models of tire cutters and see how they stack up against each other:

The first option is The Original Pink Box 3-Way Knife .

What is the Easiest Way to Cut a Tire?

There are a few ways to cut a tire, but the easiest way is to use a tire cutter. A tire cutter is a handheld tool that has a sharp blade that quickly and easily cuts through tires. Simply place the blade of the cutter on the sidewall of the tire and push down with firm, even pressure to make a clean cut.

Will an Angle Grinder Cut a Tire?

An angle grinder is a power tool that can be used for a variety of different projects, including cutting through materials like metal and tile. So, can an angle grinder cut through a tire?The answer is yes, an angle grinder can be used to cut through a tire.

However, it’s important to use the right type of blade or disc on your angle grinder in order to avoid damaging the tool or the tire. For instance, you should never use a metal-cutting blade on a tire, as this could cause the blade to shatter. Instead, opt for a carbide-tipped or abrasive cutoff wheel specifically designed for cutting tires.

When using an angle grinder to cut through a tire, always take safety precautions such as wearing eye protection and gloves. In addition, be sure to keep thegrinding wheel properly lubricated with water or coolant to avoid overheating and premature wear. With these tips in mind, you can safely and effectively use an angle grinder to cut through a tire.

Credit: www.amazon.com

Best Tool for Cutting Up Tires

If you’re looking for the best tool to help you cut up tires, look no further than the trusty old handsaw. A handsaw is the perfect tool for this job because it’s small and maneuverable, so you can get into all those tight spaces between the tire treads. Plus, it’s sharp enough to easily slice through tough rubber.

So next time you need to recycle an old tire or two, reach for your handsaw and put it to good use!

How to Cut Tractor Tires for Pulling

If you’re looking to get the most out of your tractor, then you need to know how to cut tractor tires for pulling. This process is relatively simple and only requires a few tools and materials. Here’s what you’ll need:

-Tire cutting tool (chop saw, hand held grinder, etc.)-Protective gear (gloves, glasses, etc.)-Marking pen or chalk

Once you have all of your supplies gathered, follow these steps:1. Park the tractor on a level surface and set the parking brake. You don’t want the tractor moving while you’re working on it.

2. Remove the wheel from the tractor. Depending on your model of tractor, this may require a few different steps. Consult your owner’s manual for specific instructions.

3. Use your marking pen or chalk to mark a line around the circumference of the tire where you want to make your cut. This line should be about 1-2 inches from the edge of the tire tread.

4 .

Put on your protective gear and start cutting along the marked line with your chosen tool. Be sure to work slowly and carefully so that you don’t damage the tire beyond repair.

5 .

Once you’ve made your cuts, reattach the wheel to the tractor and enjoy increased traction when pulling!

Best Way to Cut Tire Tread

One of the best ways to cut tire tread is by using a rotary cutter. This type of cutter is designed to quickly and easily cut through thick material, making it ideal for cutting through tire tread. Rotary cutters are available in a variety of sizes, so you can choose one that will fit your specific needs.

When using a rotary cutter, be sure to follow the manufacturer’s instructions carefully to avoid damaging the tool or your tires.

Conclusion

If you’re looking to cut your own loader tires, there are a few things you’ll need to keep in mind. First, you’ll need to make sure that the tire is properly inflated. If it’s not, you risk damaging the tire and causing a potential safety hazard.

Second, you’ll need to use a sharp knife or tire cutter to make clean cuts through the sidewall of the tire. And finally, you’ll want to be sure to wear gloves and eye protection while performing this task. With these tips in mind, cutting your own loader tires can be a quick and easy process.